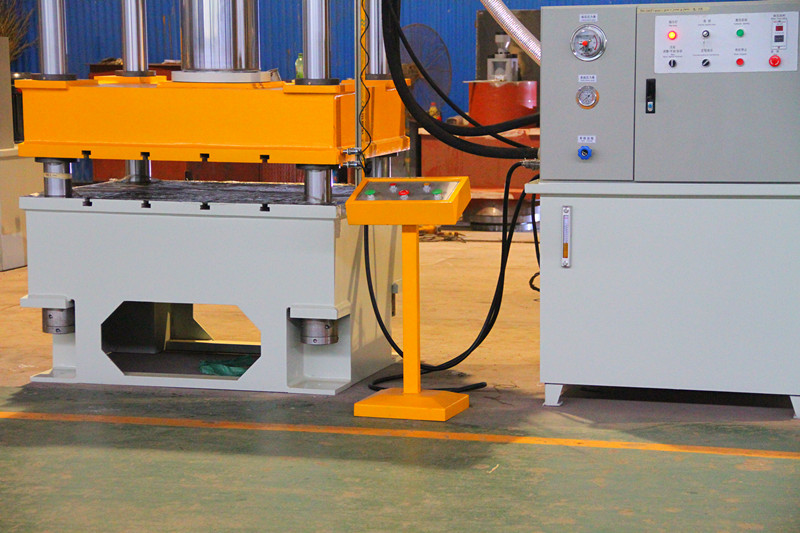

Working principle, performance and characteristics of sheet metal four-column hydraulic press machine

For hydraulic press machinees, our friends who have used them are certainly not unfamiliar. I believe there are many friends who can use hydraulic press machine proficiently,

but they don’t know how to explain hydraulic press machine. What is a hydraulic press machine?

- As the name suggests, a hydraulic press machineuses a special hydraulic oil as the working medium, a hydraulic pump as a power source, and a one-way valve to make the hydraulic oil circulate in the oil tank to make the cylinder/piston cycle work to complete certain mechanical actions as a part of productivity. Kind of machine.

- Various stamping processes, such as drawing, punching, bending, flanging, cold extrusion, metal forming, transverse pressing, bending pressing, turning through, nd correction of metal materials, can be applied to the forging forming by hydraulic press machine. It is suitable for the pressing process of plastic materials such as correction, pressing, pressing of powder products and abrasive products, and pressing of plastic products and insulating products. It is used for correction, pressing, packing, pressing and pressing. Such as powder product

- molding, plastic product molding and so on. hydraulic press machinees include hydraulic press machinees and hydraulic press machinees.

- The water-based liquid as the working medium is called a hydraulic press machine, and the oil as the working medium is called a hydraulic press machine. The specifications of

- hydraulic press machinees are generally expressed in terms of nominal working force (kN) or nominal tonnage (tons). Most hydraulic press machinees for forging are hydraulic press machinees with relatively high tonnage. In order to reduce the size of the equipment, large forging hydraulic press machinees usually use higher pressures (about 35 MPa),

- and sometimes use ultra-high pressures of more than 100 MPa. hydraulic press machinees for other purposes generally use a working pressure of 6 to 25 MPa. The tonnage

- of hydraulic press machineis lower than that of hydraulic press machine.

- Liquid frame hydraulic press machinees are mainly divided into: four-column hydraulic press machine, single-column (C type) hydraulic press machine, horizontal

- hydraulic press machine, vertical frame hydraulic press machine, gantry hydraulic press machine, etc. Among them, the sheet metal four-column hydraulic press machineis the most common.

How is the pressure formed in the hydraulic system

The pressure in the hydraulic system does not come from the oil pump (power), nor from the cylinder (load), nor from the reversing valve (command), but from the overflow valve.

The hydraulic system is usually composed of “oil pump,” “control valve”, “cylinder”, and other auxiliary equipment. The circuit designed in the hydraulic system is a process of the

sequence of hydraulic oil flow. Generally, the position of stopping the oil flow is The final return tank is ideal. When the oil is artificially cut off at this position, the oil in the entire

system will generate pressure, and the oil in the entire system will be completely cut off. The internal pressure will increase indefinitely until it explodes. Properly opening and

closing the shut-off valve is enough. When different pressures are generated, work can be done. This stop valve is actually an overflow valve. The internal structure of the overflow

valve has a cone-shaped spool. There is an adjustable spring at the back of the spool. The combined pressure of the spring spool can be adjusted manually. The meter can adjust

the ideal pressure value. In automatic operation, when the pressure is greater than the spring behind the spool, the conical port will open up, otherwise it will shrink, and the

pressure in the system will be balanced by the overflow valve.

The performance and characteristics of the sheet metal four-column hydraulic press machine

This series of hydraulic press machinees are suitable for pressing processes of plastic materials, such as stamping, bending, flanging, sheet stretching, etc. In addition, it can also be

used for calibration, press-fitting, powder product molding, and non-metallic materials compression molding.

This series of hydraulic press machinees have two electrical control systems: relay control and PLC control. There are three operation modes: adjustment, manual and semi-automatic,

and can realize two process modes: constant pressure and constant range. The large and small table surface is 160T, when the constant pressure is formed, after the pressing, there is

a delay in pressure holding and automatic return action. An ejection device is installed in the middle of the workbench, except for ejecting products. It can still be used as a

hydraulic cushion in the forming process of reverse-stretched parts. Its working pressure and stroke can be adjusted within the specified range according to the process requirements.

dee

dee