Why does a CNC sheet metal bending machine need a compensation system?

01

Bending accuracy

For bending workpieces, two precisions are the most important:

(1) Angle accuracy is mainly related to the deviation of the height direction of the mold system, see Ty in Figure 1.

(2) The dimensional accuracy is mainly related to the deviation of the front and rear direction of the mold system, see Tx in Figure 1.

Featured

This article focuses on the angle accuracy.

Figure 1. Diagram of Tx and Ty

The deeper the upper mold of the CNC sheet metal bending machine enters the lower mold, the smaller the bending angle. It can be calculated from Figure 2. When the V12 lower mold is used to bend 2mm carbon steel plates to 135°, the height direction of 0.045 mm The deviation can result in an angular deviation of 1.5°.

Figure 2. The effect of height deviation on angle deviation

02

Deflection and deformation of CNC sheet metal bending machine

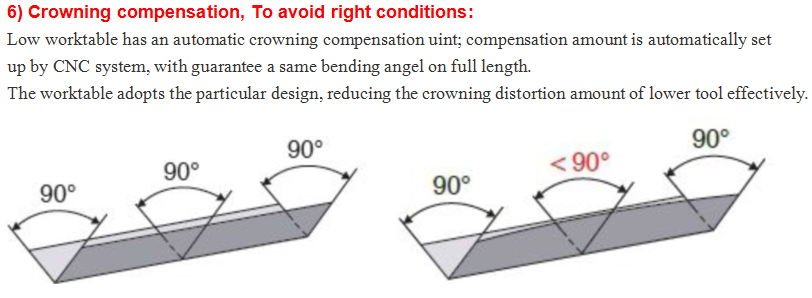

When the CNC sheet metal bending machine is bending the workpiece, due to its own structural characteristics, the upper and lower beams will be deformed due to the bending force, as shown in Figure 3.

Figure 3. Deflection and deformation of upper and lower beams

At this time, the depth of the opening of the upper mold entering the lower mold is inconsistent with the full length of the workpiece, which will cause the bending angle of the workpiece to deviate too much in the full length direction. The typical phenomenon is that the middle angle of the workpiece is large, and the angle at both ends is small, such as Shown in Figure 4.

Figure 4. Schematic of bending angle.

this is motorised cnc crowning axis of cnc electric hydraulic press brake machine.

this is manual crowning axis of NC press brake bending machine.