What is sheet metal CNC turret punching machine and how to buy sheet metal CNC turret punching machine

What is the sheet metal CNC turret punching machine? Take it literally: digitally controlled punches. What is a number? It is a string of command codes, which is the programming code that our computers often say. The official explanation is: the sheet metal CNC turret punching machine is an automatic punching machine equipped with a program control system. The control system can logically process the program with control codes or other symbolic instructions, and decode it, so as to make the punching machine operate and process the parts.

To The core position of the sheet metal CNC turret punching machine is sometimes called the brain of the sheet metal CNC turret punching machine, which is the CNC unit. English is: CNC. The CNC system in a narrow sense is a functional unit that provides users with an interactive interface and realizes position control. It contains three parts, MMI (Man Machine Interface) human-computer interaction unit, NCK (Numerical Control Kernel) numerical control core unit and PLC (Programmable Logic Controller) programmable controller. NCK is the core part of CNC. The analysis of G code and the implementation of interpolation algorithm are all done in NCK. The role of PLC in CNC is mainly to control the tool change of the punch press, spindle speed change and other places that cannot be reached by servo control, and play an auxiliary role. In fact, PLC itself is quite a computer, and it can also realize motion control functions. However, in the sheet metal CNC turret punching machine, the NCK+ servo motor can better complete the motion control, so the PLC generally does not participate in the motion control.

To Metal plate CNC turret punching machine generally consists of the following parts:

- Host, it is the subject of sheet metal CNC turret punch machinery, including punch body, column, spindle, feed mechanism and other mechanical parts. It is a mechanical part used to complete various cutting processes. To

- Numerical control device is the core of sheet metal CNC turret punching machine, including hardware (printed circuit board, CRT display, key box, paper tape reader, etc.) and corresponding software, used to input digital part programs and complete the input Information storage, data transformation, interpolation calculation and realization of various control functions. To

- Drive device, which is the drive component of the mechanical actuator of the sheet metal CNC turret punch press, including the spindle drive unit, feed unit, spindle motor and feed motor. Under the control of the numerical control device, it realizes the spindle and feed drive through the electric or electro-hydraulic servo system. When several feeds are linked, the processing of positioning, straight line, plane curve and space curve can be completed. To

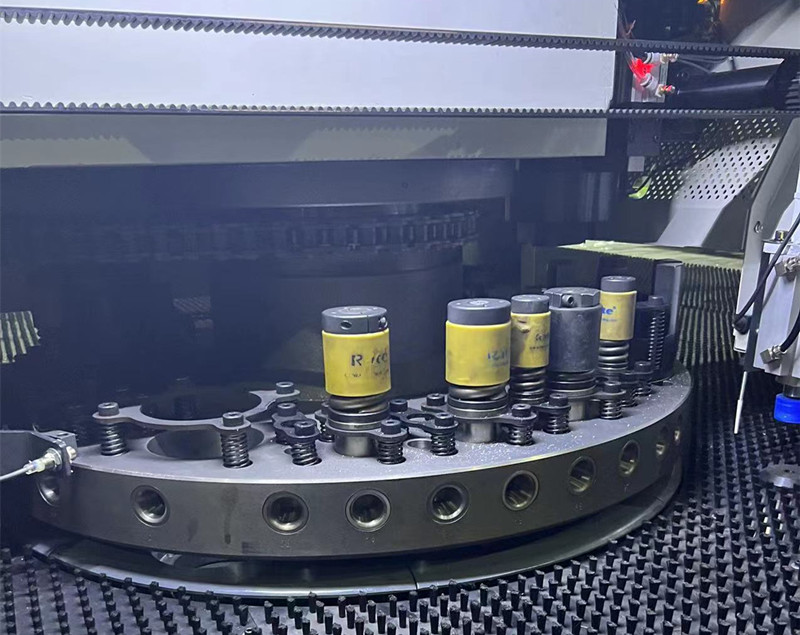

- Auxiliary device refers to some necessary supporting parts of the sheet metal CNC turret punching machine, used to ensure the operation of the sheet metal CNC turret punching machine, such as cooling, chip removal, lubrication, lighting, monitoring, etc. It includes hydraulic and pneumatic devices, chip removal devices, exchange tables, CNC turntables and CNC indexing heads, as well as cutting tools and monitoring and testing devices. To

- Programming and other ancillary equipment can be used to program and store parts outside the machine.

Metal plate CNC turret punching machine can be used for all kinds of metal sheet parts processing. It can automatically complete a variety of complex hole types and shallow stretch forming processing at one time. (Automatically process holes of different sizes and different shapes according to requirements Small punching dies can be used to punch large round holes, square holes, waist-shaped holes, and various shapes of curve contours, and special process processing, such as shutters, shallow stretching, countersinking, flanging holes, and reinforcing ribs can also be carried out. , Imprinting, etc.).

Primapress sheet metal CNC turret punching machine can be widely used in sheet metal processing, solar energy industry, building curtain wall decoration industry, electric cabinets, kitchenware, distribution boxes, food machinery, elevators, shipbuilding, trains, subways, high-speed rail, aerospace, Military industry, air conditioning, metal furniture, warehousing and logistics equipment, and other cold stamping processing fields.

Compared with ordinary punches, the advantages of metal plate CNC turret punching machines are: through simple mold combination, a large amount of mold costs can be saved, low-cost and short-period processing of small batches and diversified products can be used, with greater processing Scope and processing capacity, so as to adapt to market and product changes in time. To

The metal plate CNC turret punching machine is an abbreviation of digital control punching machine, which is an automated machine tool equipped with a program control system. The control system can logically process the program with control codes or other symbolic instructions, and decode it, so as to make the punching machine operate and process the parts. That is to say, the following aspects should be considered when choosing sheet metal CNC turret punching machine:

(1) Metal sheet CNC turret punching machines are distinguished from the source of power. At present, there are mechanical sheet metal CNC turret punching machines, hydraulic sheet metal CNC turret punching machines, and servo-type sheet metal CNC turret punching machines.

(2) According to the number of turret mold positions, there are small turret punches with 6-8 stations, large turret punches with 16 stations or more, and the number of stations tailored to customer needs.

(3) In terms of usage, it includes chassis cabinets, solar processing, auto parts, screens, kitchen utensils and various sheet metal processing.

(4) From the processing objects, it can be divided into: thin plate processing and thick plate processing metal plate CNC turret punching machine.

Metal plate CNC turret punching machine can be used for all kinds of metal sheet parts processing. It can automatically complete a variety of complex hole patterns and shallow deep drawing processing at one time. Through a simple mold combination, compared with traditional stamping, it saves a lot of money. For mold costs, low-cost and short-period processing can be used to process small batches and diversified products, with a large processing range and processing capabilities, so as to adapt to market and product changes in time. Save manpower and improve production efficiency.