What are the factors of metal fiber laser cutting machine processing accuracy?

Compared with the traditional processing technology, the metal fiber laser cutting machine has higher processing accuracy and better cross-sectional effect without secondary processing. This is also the reason why many companies choose the metal fiber laser cutting machine. However, many companies have found that the cutting accuracy of fiber laser cutting equipment is sometimes not ideal, which affects the subsequent processing flow. So what factors affect the machining accuracy?

1. Processing material

When the fiber laser cutting machine processes metal, the cutting accuracy is different for different materials. Even if it is the same material, if the composition of the material is different, the cutting precision will be different. Therefore, the material of the workpiece also has a certain influence on the accuracy of fiber laser cutting. Generally, the smoother the material, the higher the processing accuracy.

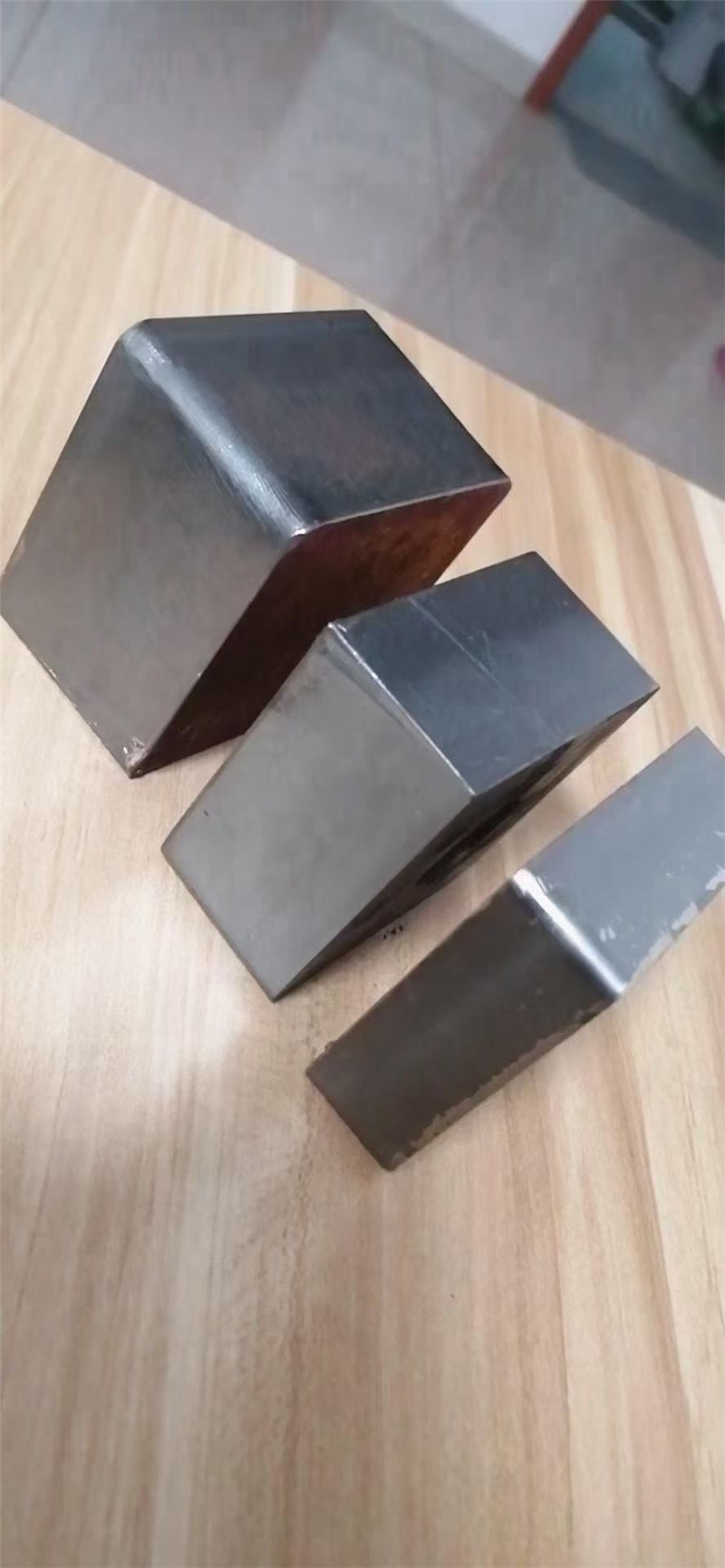

Therefore, when processing different metal materials, you can make samples in advance to find out the parameter settings that are more suitable for this type of material.

2. The shape of the fiber laser beam

The light beam emitted by the fiber laser of the metal fiber laser cutting machine is tapered, so the cut gap is also tapered. The shape of the fiber laser beam is also a major factor affecting the cutting accuracy of the metal fiber laser cutting machine. The smaller the spot of the fiber laser beam is, the smaller the slit and the higher the processing accuracy.

Under the condition of this tapered fiber laser beam, the greater the thickness of the workpiece, the lower the accuracy, and therefore the larger the slit. Therefore, when processing metals of different thicknesses, choosing the appropriate fiber laser power can achieve better results.

3. The accuracy of the workbench

When the metal fiber laser cutting machine is processing, the worktable vibrates with the vibration of the fiber laser head. A high-precision worktable with stable linear guides and stepping motors will have higher cutting accuracy; if the worktable is uneven or other reasons, it will also affect the processing accuracy of the fiber laser cutting machine.

4. Auxiliary gas and nozzle

During the processing of the metal fiber laser cutting machine, the auxiliary gas and the nozzle play the role of cleaning and controlling the cutting speed. The uneven pressure and temperature in the air flow will cause changes in the density of the air flow field, thereby constricting the focus of the beam energy, causing refocusing or beam divergence, and affecting the accuracy of metal cutting.