What are the circular rolling processes for CNC plate bending rolling machines?

Primapress brand

Professional manufacturer of CNC Press brake, CNC shearing machine and CNC bending rolling machine

The rolling machine is mainly composed of a host, a transmission system, a control system, and auxiliary devices. Among them, the host is the main part of the rolling machine, including the upper and lower rollers.

By adjusting the distance and angle between the upper and lower rollers, the bending rolling degree and curvature of the metal sheet metal by the rolling machine can be controlled. The transmission system is mainly the power source of the plate rolling machine, responsible for driving the roller or drum components of the plate rolling machine for plate rolling processing.

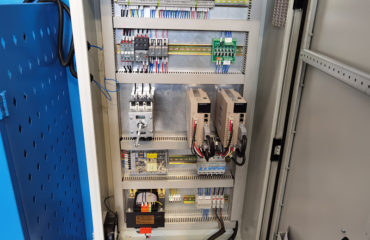

The control system is the core part of the rolling machine, which ensures the stability and safety of the rolling machine through control and monitoring. The auxiliary devices are mainly used to improve the production efficiency and quality of the rolling machine, including feeding devices, clamping devices, protective devices, etc.

There are two existing cylinder rolling processes.

The first method is to use a three roll bending rolling machine with pre bending rolling function. Press the head of the sheet metal into the required arc on the bending rolling machine, and roll the pre bent sheet metal into a circular cylinder on the bending rolling machine; Then perform straight seam welding, calibration, non-destructive testing, and heat treatment (as needed). Although the general bending rolling machine with pre bending rolling function can meet the requirements, the net space between the rollers of the bending rolling machine cannot meet the width size of the steel plate, so a large bending rolling machine is necessary.

The second method is to use a four roll bending rolling machine with pre bending rolling function to directly roll and form. The investment of a four roll plate rolling machine is also much greater than that of a regular three roll plate rolling machine. Both methods require significant equipment investment. Both of these traditional barrel rolling processes will increase production costs for enterprises.

The above are two common round rolling processes that enterprises can choose based on their own needs and budget.