What are the advantages of 4kw 6kw fiber laser cutting machine over traditional cutters

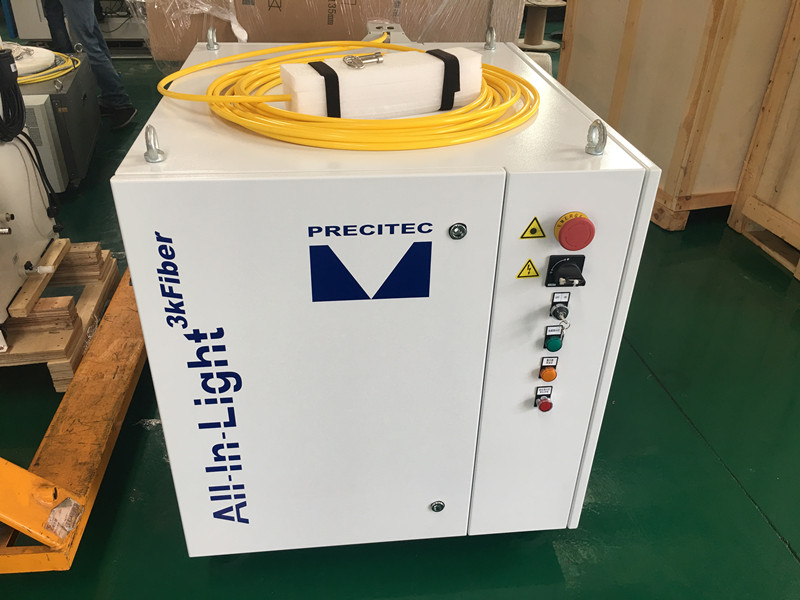

Although 4kw 6kw fiber laser cutting machine have been on the market for many years and have matured, many users do not understand the

advantages of laser cutters. 4kw 6kw fiber laser cutting machine as an efficient processing equipment, can completely replace the traditional cutting equipment.

Many users say the machine is better suited for modern product processing. So what are the outstanding advantages of this 4kw fiber laser cutting machine

over traditional types of tools?

- Cutting processing speed.

According to the actual test results of laser field, the cutting speed of 4kw 6kw fiber laser cutting machine is more than 10 times that of traditional cutting equipment.

For example, cutting 1mm stainless steel plate,4kw 6kw fiber laser cutting machine maximum speed can reach more than 30 meters per minute, which is not possible

with conventional cutting machines.

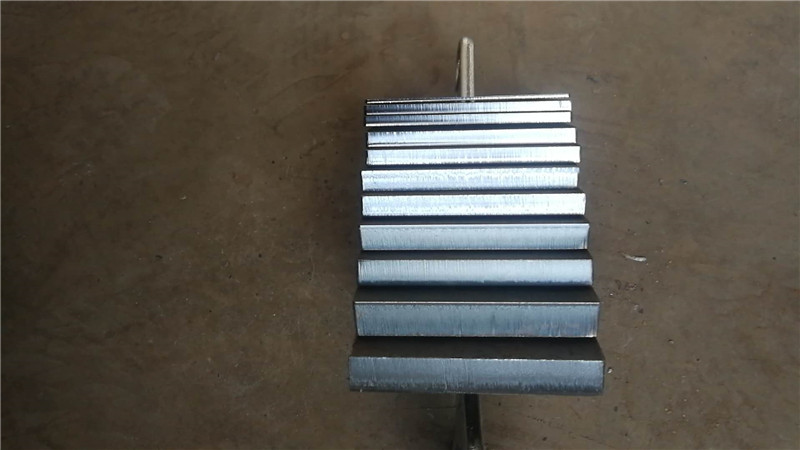

- The quality and precision of the cut.

Traditional flame cutting and CNC punches are contact-type processing methods, for the material damage is very large, cutting quality is very low, must go through

secondary processing to make the surface flat, and cutting accuracy deviation is very large. And the 4kw 6kw fiber laser cutting machine is a non-contact mechanic way,

for the material damage is almost zero, because the 4kw 6kw fiber laser cutting machine uses advanced accessories to make the equipment more stable in operation,

cutting accuracy more accurate, error even reached 0.01mm accuracy, cutting surface flat and smooth. For some demanding industries not only save costs but also processing time.

- The operation is simpler and more convenient.

Flame cutting and CNC punches are required to intervene in the operation of the machine, especially CNC punches, it is necessary to design a mold before cutting.

4 kw laser cutting machine only need to design a good cutting pattern in the computer, any complex pattern can be imported into the laser cutting machine’s work station,

the equipment will be automatically processed, the whole automation without human intervention.

- Fast cutting speed, high degree of automation, easy to operate, low labor intensity, no pollution.

Now is a efficiency-demanding society, everything needs to be fast and good. In the cutting of materials, more efficiency is required. Traditional cutting machine

because of heavy operation, slow work efficiency has been gradually eliminated by the market, 4kw 6kw fiber laser cutting machine is now the darling of the market.

Because this machine not only in the line cutting more uniform precision, but also improve productivity, bring more production value.