Use problems and solutions of hydraulic swing beam sheet metal shearing machine

The hydraulic swing beam sheet metal shearing machine is an important equipment in the forging industry. Whether the expected shearing action can be realized is the premise of ensuring the accuracy. In the past, the conventional design mainly relies on experience and analogy to the same type of machine, and the design is repetitive, the cycle is long, and the reliability is poor. The machine not only has the function of a common sheet metal shearing machine, but also has a side cutter, and can meet the trimming and shearing of long sheets. It has a relatively broad application prospect in steel rolling, boiler, shipbuilding and other industries.

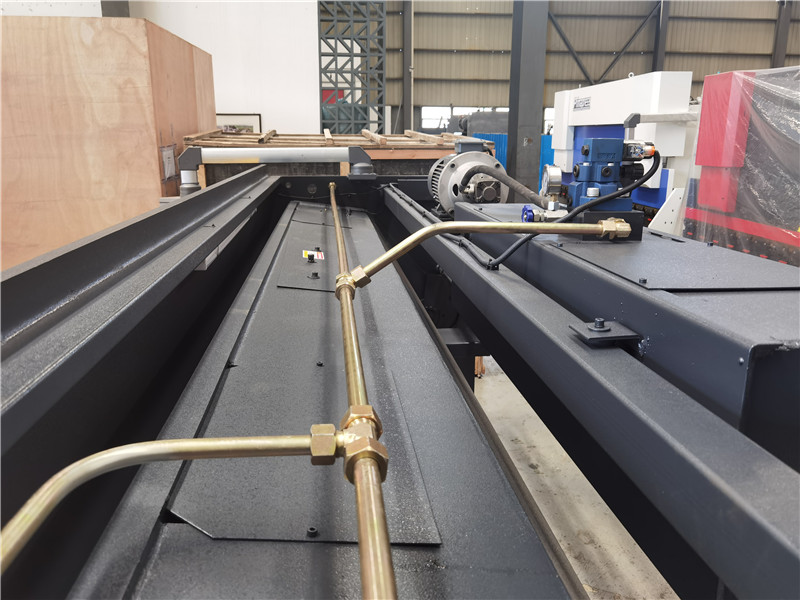

The hydraulic swing beam sheet metal shearing machine is mainly composed of frame, tool rest, oil cylinder, pressing foot, alignment device, gap adjustment device, hydraulic system and electrical system. When the sheet metal shearing machine cuts the sheet, the pressure setting value of the hydraulic system and the cutting edge clearance value directly affect the quality of the incision. The hydraulic system is composed of an integrated block valve, motor, oil pump and its pipelines in a cartridge structure. The hydraulic directional control valve, pressure control valve and flow control valve can no longer meet the parameter requirements of this system, so the cartridge valve structure is adopted. Hydraulic system. The hydraulic system of the cartridge valve is a combination of several cartridge components and corresponding pilot control stages to form control valves such as directional control, pressure control, flow control and compound control. It has obvious advantages such as automation, so it has become the leading control product in the field of high pressure and large flow.

Since most of the hydraulic swing beam shears are manufactured with a simplified process, the blade mounting surface is simplified from a space helical surface to a plane, resulting in changes in the shearing gap and shearing back angle during the shearing process. The change of the shear gap will change the size of the shear force during the shearing process, and the shear quality will decrease; and the change of the shear back angle can aggravate the wear and even extrusion of the blade and the plate, thereby increasing the shear force. Therefore, the shear force value calculated by the Nosali formula is only used as a reference value for adjusting the shear force. The shear force required in the actual shearing process is obtained through continuous adjustment on the production site supplemented by shearing tests. of.

Therefore, when dealing with the hydraulic system failure of the cartridge valve structure, it is necessary to clearly understand the role of each element in the system, and if necessary, it can be equivalently simplified to an ordinary hydraulic valve, so as to more intuitively analyze the entire cartridge circuit. The function of the hydraulic system, so as to quickly and accurately find out the system fault and eliminate it in time.

During the use of the sheet metal shearing machine, it is necessary to strictly follow the operating procedures

sheet metal shearing machine is a kind of equipment that can cut the metal sheet, automatically count, and send it to the next process by the feeding car according to the processing requirements. It is a kind of shearing equipment that is widely used in machining. It can cut steel plate materials of various thicknesses and can be classified into three types: flat shearing, rolling shearing and vibration shearing.

The automatic sheet metal shearing machine is a kind of automatic processing equipment that precisely controls the processing size of the sheet, performs automatic cyclic shearing processing of large metal sheets, and transports it to the next process by the feeding car. This equipment is used for sheet metal cutting machine tools on the production line. It can cut the sheet metal according to the processing requirements, collect it by the feeder, and automatically ship it to the production line.

The maintenance method of the sheet metal shearing machine:

- Operate in strict accordance with the operating procedures.

- Add lubricating oil according to the requirements of the lubricating chart at regular time, fixed point, and quantitatively before each startup. The oil should be clean and free of precipitation.

- The machine tool needs to be kept clean frequently, and the unpainted part is rust-proof grease.

- The lubricating oil in the motor bearing should be replaced and refilled regularly, and the electrical parts should be checked regularly to see if they are working normally, safely and reliably.

- Regularly check whether the V-belts, handles, knobs and buttons are damaged. If they are seriously worn, they should be replaced in time and reported for spare parts.

- Regularly check and repair switches, insurances, handles, and ensure their reliable work.

- 10 minutes before leaving get off work every day, lubricate the machine tool and scrub and clean the machine tool.

- It is strictly forbidden for non-designated personnel to operate the equipment. Usually, people need to leave the machine and stop.

Precautions for the use of shears:

- This equipment requires special personnel to be responsible and operated by special personnel. The operator should be familiar with the structure and performance of the machine.

- This equipment is used to cut metal plates with a thickness of 1-12mm and a width smaller than the width of the shearable plate. The sheared plate is based on low carbon steel with a tensile strength of 450N/mm2 and an elongation of 25%. For shearing stainless steel plate, the shearing thickness is 1-6mm.

- Before starting the machine, check whether all parts of the machine are normal, and all sundries and tools should not be stacked on the workbench.

- The operator must not remove the guardrail, and must not put his hand deep between the upper and lower blades. It is necessary to stop the machine when picking up and cutting the workpiece, and at the same time avoid the moving parts at the rear of the machine from hurting people.