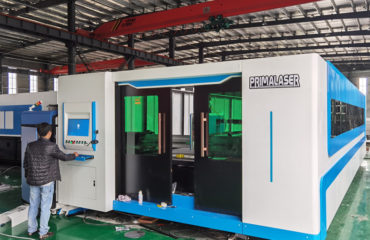

The relationship between cutting speed and cutting effect of metal fiber laser cutting machine

As we all know, the metal fiber laser cutting machine has a good cutting effect for most types of metal materials, whether it is a high-hardness or thicker plate, the metal fiber laser cutting machine can efficiently complete the cutting process. Except for some highly reflective metal materials, such as copper and aluminum, the use of metal fiber laser cutting machines for cutting can have an ideal cutting effect.

The metal fiber laser cutting machine adds auxiliary vapor suitable for the material to be cut during the cutting process. When steel is cut, oxygen is used as an auxiliary vapor to produce an exothermic chemical reaction oxidizing material with molten metal, and at the same time, it helps blow away the slag in the slit. Compressed air is used to cut polypropylene and other plastics, and inert vapor is used to cut flammable materials such as cotton and paper. The auxiliary vapor entering the nozzle can also cool the focusing lens, preventing smoke and dust from entering the lens holder to contaminate the lens and cause the lens to overheat.

Laser cutting has no burrs, wrinkles, and high precision, which is better than plasma cutting. For many electromechanical manufacturing industries, because the modern laser cutting system controlled by the computer program can easily cut workpieces of different shapes and sizes, it is often preferred to the punching and molding processes; although the processing speed of laser cutting is slower than that of molds. However, it has no mold consumption, no need to repair molds, and save time for mold replacement, thereby saving processing costs and reducing production costs, so it is more cost-effective to consider overall.

The relationship between cutting speed and cutting effect of metal fiber laser cutting machine

The choice of cutting speed for CNC metal fiber laser cutting machine is also very important when cutting. The best cutting speed range can be selected according to the equipment description or determined by experiment. Due to the thickness of the material, the material is different, the melting point is high, and the thermal conductivity Factors such as the size and surface tension after melting, the cutting speed also changes accordingly.

main performance:

- A moderate increase in the cutting speed can improve the quality of the incision, that is, the incision is slightly narrower, the surface of the incision is smoother, and the deformation can be reduced.

- The cutting speed is too fast so that the cutting line energy is lower than the required value, and the jet in the cutting seam cannot quickly blow off the molten cutting melt immediately and form a large back drag, accompanied by cutting slag and cutting The surface quality is degraded.

- When the cutting speed is too low, because the cutting site is the anode of the plasma arc, in order to maintain the stability of the arc itself, the anode spot or anode area must find a place to conduct current near the slit closest to the arc, and it will flow to the jet at the same time. More heat is transferred in the radial direction, so that the incision becomes wider. The molten material on both sides of the incision gathers and solidifies at the bottom edge, forming dross that is not easy to clean, and the upper edge of the incision becomes rounded due to excessive heating and melting.

- When the speed is extremely low, the arc may even go out due to the wide incision. It can be seen that good cutting quality and cutting speed are inseparable.

How to improve the smoothness of the cutting surface of the fiber metal fiber laser cutting machine

- Check whether the belt tension of the fiber metal fiber laser cutting machine is proper. If not, please adjust in time.

- Check whether the cutting speed of the fiber metal fiber laser cutting machine is too fast, which affects the non-smooth section of the material to be cut. If so, please appropriately reduce the operating speed of the fiber metal fiber laser cutting machine.

- Check whether the lens of the fiber metal fiber laser cutting machine is too dirty and the molding section is smooth. If yes, cut off the power supply and clean with professional cleaning agent.

- Check whether the optical fiber metal fiber laser cutting machine is uneven due to loose optical path. If so, tighten this smooth road in time.

- Check whether the section of the fiber metal fiber laser cutting machine is not smooth due to the excessive vibration of the table. If so, please check whether the screws on the table to fix the floor are loose or fall off. If so, please deal with it in time.

After all the above situations are checked, the unsatisfactory surface finish of the general fiber metal fiber laser cutting machine can be effectively solved! To get a good cutting surface finish, you need to pay attention to the details of the equipment during the operation of the metal fiber laser cutting machine. If you have other questions about the fiber metal fiber laser cutting machine, you can contact Prima Laser in time!