The function and acceptance criteria of automatic servo turret CNC punch machine

The automatic servo turret CNC punch machineing machine can be used for the processing of various metal sheet parts, and can automatically complete a variety of complex hole patterns and shallow drawing forming processing at one time. The small die punches large round holes, square holes, waist-shaped holes and various shapes of curved contours by nibbling.

Through simple die combination, compared with traditional stamping, a lot of die costs can be saved, small batches and diversified products can be processed at low cost and short cycle time, and it has a large processing range and processing capacity, so as to timely adapt to the market with product changes.

Acceptance standard for automatic servo turret CNC punch machine press

- The parts are complete and the quality meets the standard.

- The control handle and buttons of the automatic servo turret CNC punch machinepress are intact.

- The surface of the CNC turret punch press is smooth and has no serious touching, pulling and grinding.

- Automatic servo turret CNC punch machineclamp, lubrication pump, hydraulic pipeline, oiler, CNC turret mold, globe valve, etc. are complete and easy to use.

- The limit switch, press insurance, lead screw safety raft, etc. are complete and reliable.

- The CNC turret punch press operates normally and has good performance.

- The main machining accuracy of the servo turret CNC punch machinepress meets the specified requirements.

- The performance and efficiency of CNC machine tools maintain the original design capabilities or meet customer process requirements.

- The transmission system has a sensitive response, normal operation, no noise and vibration.

- The CNC turret punch is flexible and accurate in operation, and the turret positioning is stable and reliable.

- The electrical and hydraulic systems of the machine tool are in normal operation and have good performance.

- The technical information is complete and accurate.

- The random manual, certificate of conformity and other materials are complete.

- The technical files, operation records, maintenance records and other information of the CNC turret punch press are complete and accurate.

- After-sales service personnel are in place, and installation training is serious.

- The environment of servo turret CNC punch machinepress is neat and clean.

- The surface of the servo turret CNC punch machinepress is clean, free of grease, rust, large-area paint stripping, and the feeding brush platform has no hair removal phenomenon.

- The surroundings of the servo turret CNC punch machinepress are neat, clean, and free of accumulation of stamping waste and debris.

- The CNC turret punch press accessories and special tools are complete, well kept and neatly placed.

An introduction to the components of a CNC punch and how to use it

In the machining industry, a punch press is an essential piece of equipment. By using a punch, we are able to produce parts in batches. So, how much do you know about the punch itself? Today we will talk about some things about the punch. Now, let’s take a look at it together. The following is an introduction to the “introduction to the components of CNC punch presses and their use”.

【How to master the main points of CNC punching machine】

- The structure is mainly composed of three parts: a special deep throat punch, a platform feeding body and a special automatic mold.

- Deep throat pneumatic clutch punch, welded body, stable performance.

- The control unit adopts an industrial-grade integrated workstation, which is anti-vibration and anti-interference, and is suitable for working in harsh environments. The software uses ST-V8.5, independent research and development, free upgrade, easy to learn, more user-friendly; no programming required, AutoCAD graphics are automatically converted into processing programs, self-contained mold library management, automatic plate repositioning, one-click operation batch Processing, breakpoint processing, piece count display, simulation display processing track, equipment dry run diagnosis and other functions.

- The work table adopts the universal ball work table, the feeding is smooth and no resistance, and the board will not be scratched.

- Deep throat start clutch punch, welded body, stable performance.

- The feeding body has an ultra-wide guide rail spacing, which runs smoothly and ensures the feeding accuracy. CNC bending machine

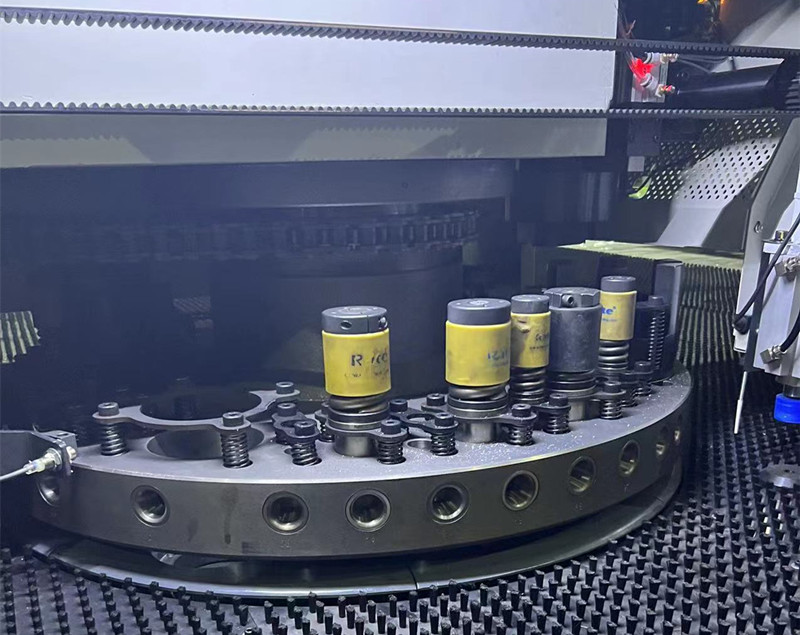

- The turret mold has a special structure, simple design and sophisticated conception. The upper and lower mold plates are precisely locked and positioned at one time to ensure the coaxiality, and the mold can be quickly changed by rotating the striking head.

- The main transmission components and electrical appliances are imported configuration.

- Thin oil is automatically circulated and lubricated to reduce the friction of each motion pair.

【Application of CNC punching equipment】

With the rapid development of science and technology, CNC punching equipment has been applied to machine tools, machinery, sheet metal and other industries. High technology leads all industries to gradually move towards automation and numerical control. The processing equipment from the original manual to the current computer control, this is a qualitative leap, and the mechanical accessories are also strict at the same time. Let’s analyze the application of punching sieve plate in CNC punching machine.

Since the rise of the numerical control industry, machinery has been numerically controlled. Numerical control is also applied in the punching screen industry. The thickness of the CNC punching screen plate is small, which has nothing to do with the external force. Because of this factor, we can zero the self-stress of the vertical plate surface. principal stress.

Due to the small thickness of the plate, these two principal stresses are generally considered to be uniformly distributed in the direction of the thickness force. Under the action of these two forces, the tension of the punching screen plate can play a role.

The above introduction to “how to master the main points of CNC punching machine” and “the application of CNC punching machine equipment”, I hope to help you understand the “introduction of the components of CNC punching machine and how to use it.