The difference between metal fiber laser tube cutting machine and plate tube integrated fiber laser cutting machine

The output and demand of stainless steel pipes and plates in my country are relatively large at present, and pipe cutting processing technology naturally needs to keep pace with the times.

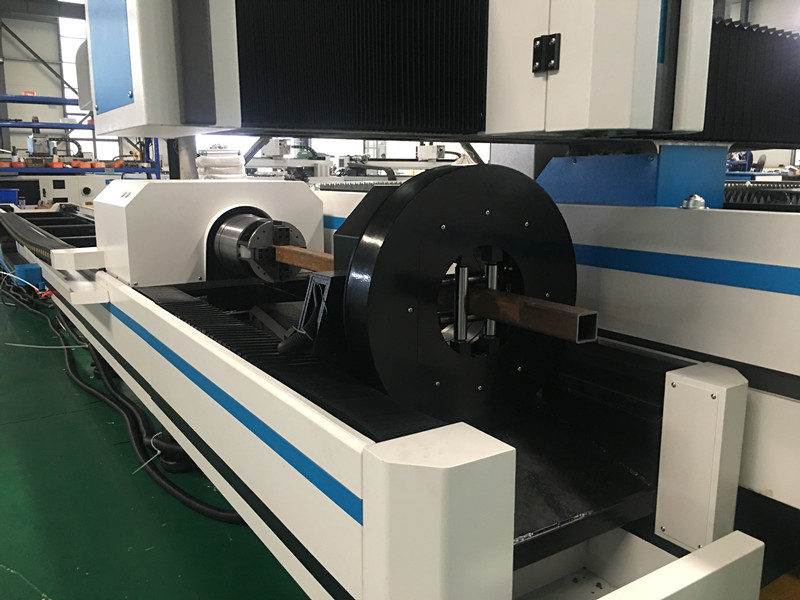

Pipe processing technology also develops rapidly, especially the advent of metal fiber laser pipe cutting machine Processing has brought an unprecedented qualitative leap. As a special metal fiber metal fiber laser cutting machine, the metal fiber laser pipe cutting machine is mainly used for metal fiber laser cutting of metal pipes. It is suitable for cutting various shapes of pipes: square pipes, round pipes, T-shaped pipes, U-shaped pipes, Various pipes such as grooved pipes and angle pipes. The metal fiber laser pipe cutting machine has the following functions: hole drilling, bevel cutting, 45 degree cutting, butt cutting, bevel cutting, hollow punching, etc. Many pipe processing manufacturers should have doubts before purchasing equipment that “the difference between metal fiber laser pipe cutting machine and plate and tube integrated fiber laser cutting machine”, let’s talk about this next!

Sheet and tube integrated fiber laser cutting metal fiber metal fiber laser cutting machine can cut plates and tubes with high accuracy. Metal fiber laser tube processing has higher accuracy especially for thin-walled tubes. This kind of tube is drilled, milled or sawed in accordance with the traditional The cutting method may be deformed. Cost-saving. Manufacturers whose products include both 3m or 6m tubular and metal plate components can process both on one machine tool, thus saving costs and being used in two separate metal fiber metal fiber laser cutting machines. Trouble back and forth.

The difference between metal fiber laser tube cutting machine and plate tube integrated fiber laser cutting machine

The plate and tube integrated fiber laser cutting machine has been widely used in modern industry due to its advantages of wide cutting range, fast cutting speed, narrow cutting seam, good cutting quality, small heat-affected zone, and large amount of addition. Metal fiber laser cutting technology has also become one of the more mature technologies in metal fiber laser processing technology. The plate and tube integrated fiber laser cutting machined pipe fittings achieve zero backlog inventory, and the actual flexibility of metal fiber laser processing can meet the convenient changes in use, effectively prevent the differentiated production of products, and reduce the risk of product backlogs and defects. Metal fiber laser cutting machine is especially for materials with high hardness, high brittleness and high melting point.

Metal fiber laser pipe cutting machines have made continuous breakthroughs in the development of recent years. Major manufacturers have successively introduced metal fiber laser pipe cutting machines that can achieve various pipe cutting effects. In terms of the diversity of pipe cutting, it is metal The fiber laser plate and tube integrated fiber laser cutting machine is incomparable. In the tube cutting, the metal fiber laser tube cutting machine is naturally superior. When cutting some special pipes, the tube-sheet integrated fiber laser cutting machine cannot replace it.

If you are a manufacturer focusing on pipe cutting, it is recommended to choose a professional pipe cutting machine.

In recent years, the tube-sheet integrated fiber laser cutting machine has become more and more perfect, and its own control software has a wealth of cutting technology and cutting experience.

If CNC workers operate the plate and tube cutting integrated fiber laser cutting machine proficiently, it can realize very good cutting of plates and pipes. It has a two-way cutting function. The manufacturer can realize multiple uses of a machine, save space, and have the best of both worlds.

Metal fiber laser tube cutting machine and tube sheet integrated fiber laser cutting machine each have their own advantages. It still needs to be determined according to the user’s own cutting process. Focus on tube cutting and choose metal fiber laser tube cutting machine. If both tube and sheet cutting are involved, purchase The tube-sheet integrated fiber laser cutting machine is

also a good choice.