The advantages of sheet metal fiber laser cuttingreplacing traditional cutting

In the past, the processing of such three-dimensional panels was mainly carried out using a press to press the production mold. This method is suitable for occasions with limited categories, single variety production, and large quantities. However, with the increasing variety and dispersion of customer workpieces, the traditional production method of presses requires a complete sequence of molds and presses (usually 3 to 6 presses) for each type of stamping part. Moreover, the stamping process is complex, and mold repair is time-consuming and labor-intensive. In terms of time and cost, this method is increasingly unable to meet the production needs of customers.

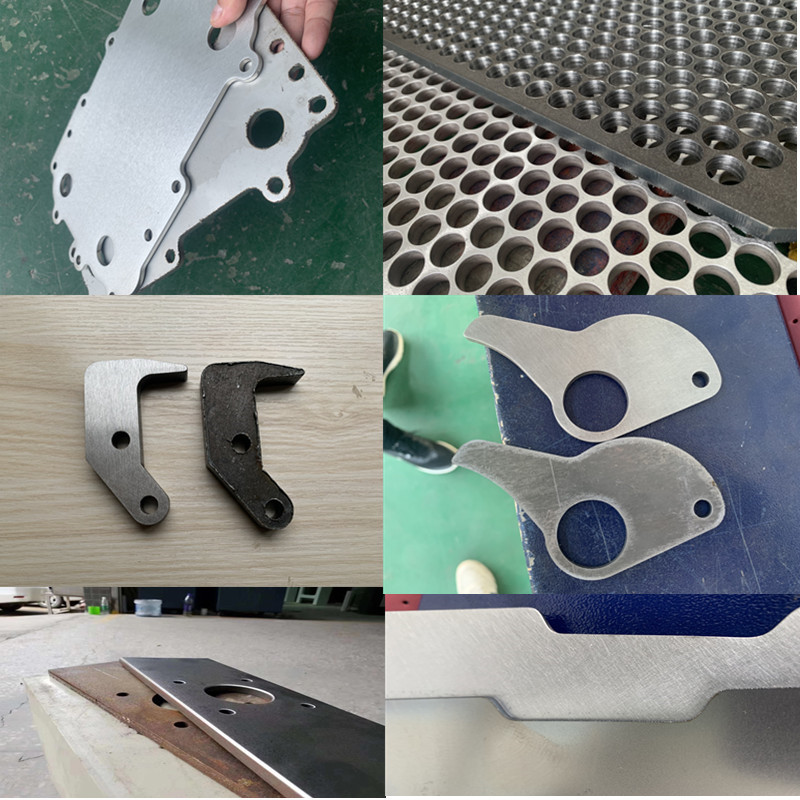

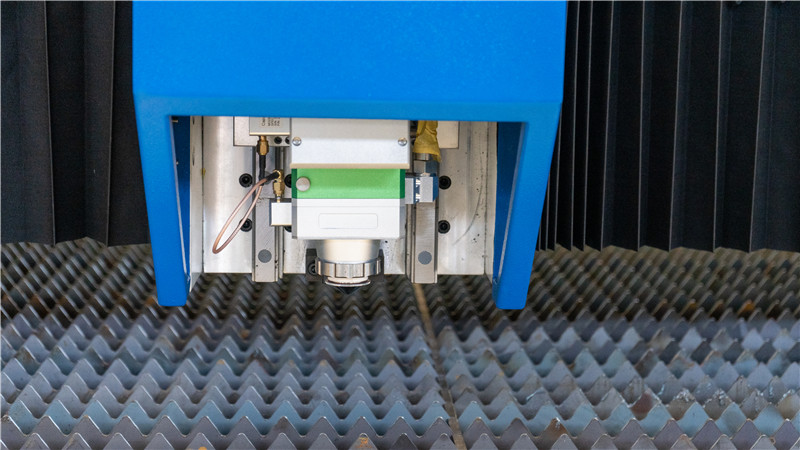

Traditional sheet metal fiber laser cuttingequipment can only cut flat plates or standard circular and square tubes. With the development of the sheet metal fiber laser cuttingindustry, there have been some changes, including the quality, thickness, and shape of the cutting materials; The improvement of machine power and efficiency has enabled sheet metal fiber laser cuttingto efficiently process components such as automobiles, rail transit, aircraft manufacturing, electromechanical bathrooms, 3D advertising signs, fitness equipment, and more with higher speed and accuracy.

Although the development of China’s laser industry is a preliminary development, it has achieved a leapfrog development under the leadership of international technology, with a stage of higher quality highlights than the same. As for sheet metal fiber laser cuttingmachines, the market demand is high, adding new vitality to the vast market. With the development of the laser industry, a complete set of laser industrial equipment has also entered the production market. It has freed itself from long-term dependence on foreign countries and solved the awkward situation in the domestic laser industry.

Those who understand the sheet metal fiber laser cuttingmarket are well aware that sheet metal fiber laser cuttingcan process multiple industries, and equipment for processing multiple industries is expensive. If you purchase single industry equipment, such as metal sheet metal fiber laser cuttingmachines, leather sheet metal fiber laser cuttingmachines, etc., these targeted industry equipment will not be as expensive. Small and micro processors who are new to the laser industry use laser equipment to process their products in a sheet metal fiber laser cuttingprocessing mode, but it is no longer advocated nowadays. Because this is a period of rapid development in the sheet metal fiber laser cuttingindustry, the advantages of flexible processing by sheet metal fiber laser cuttingmachines have replaced traditional metal processing methods. This high-precision laser processing method has been greatly popularized, and the price of laser equipment is no longer that high.

Nowadays, low-power equipment can also be used for processing, which eliminates the need to borrow someone else’s equipment for processing when purchasing a sheet metal fiber laser cuttingmachine. The gradual replacement of sheet metal fiber laser cuttingprocessing mode may be inevitable and also a future market. In terms of its processing effect, the processing effect of a single industry is definitely the best for a single industry, and it can also meet the requirements of this industry to a greater extent. And generally, large-scale manufacturing enterprises will provide equipment operation training to customers who purchase equipment, as long as the company has some technical processing background personnel, it is relatively easy to get started. Therefore, if you want to use sheet metal fiber laser cuttingprocessing for BOSS, you can try using sheet metal fiber laser cuttingequipment to directly purchase and process, which can help you achieve and solve many problems!