Several factors to consider before buying a metal fiber laser cutting machine

1. The materials processed by the company and the scope of business needs

First of all, you must consider your business scope, what materials you need to cut, the thickness of the cutting material and other factors, and then determine the power size of the purchased equipment and the size of the worktable according to your needs. At present, the power of the metal fiber laser cutting machine on the market is from 1000W-30000W In between,

manufacturers of average workbench sizes can customize it according to customer needs.

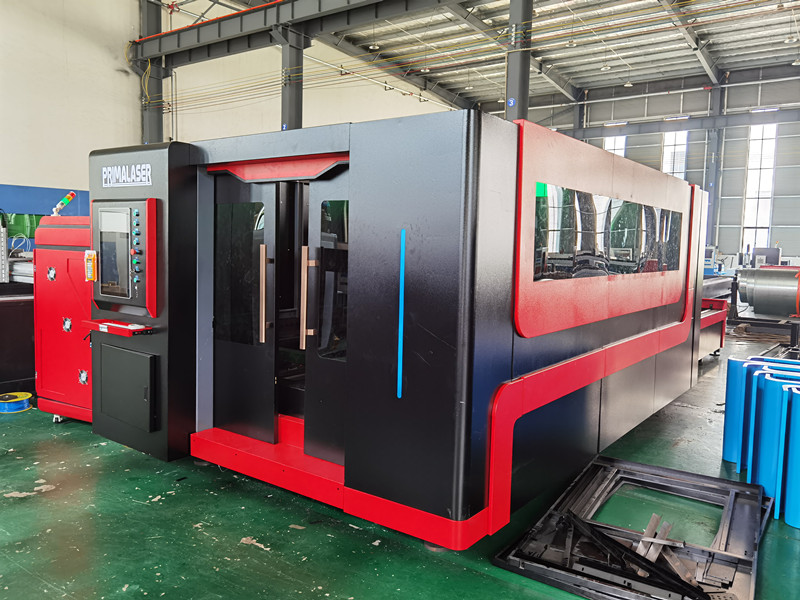

2. The initial selection of the manufacturer

To determine the needs, you can go to the market to find out or go to the peers who have bought a metal fiber laser cutting machine to see the machine performance and basic parameters first. Choose a few powerful manufacturers with preferential prices for early communication and proofing. Later, you can conduct on-site inspections, and conduct more detailed discussions on equipment prices, equipment training, payment methods, and after-sales service.

To

3. The size of the laser power

When choosing the performance of the metal fiber laser cutting machine, it is important to fully consider your own environment and the size of the laser power. If you often cut thin metal plates below 10mm, then choose a metal fiber laser cutting machine of 1000W-2000W It can meet the needs of production. If you cut materials over 6mm, you need to consider more powerful equipment, which will help companies control costs.

4. The core part of the metal fiber laser cutting machine

Pay special attention to some important parts of metal fiber laser cutting machine when purchasing. Especially the laser generator, laser cutting head, servo motor, guide rail, water tank and

other accessories. These components will directly affect the cutting speed and accuracy of the metal fiber laser cutting machine. It is necessary to distinguish whether it is imported or domestic, because many domestic manufacturers use domestically-made fake imported parts to deceive customers.

To

5. Equipment quality and stability in use are also very important metrics

Today’s product upgrades are getting faster and faster. Because of the short product development cycle, there are more product diversity, sample trial production, and mass production. How to complete customer orders with quality and quantity, enhance corporate competition, and maintain corporate reputation is also every time A business operator has to face arduous tasks, so purchasing processing equipment with stable performance is the prerequisite and basis. Try to choose a brand with a high market share, a sound after-sales service system, a large number

of after-sales service outlets, and long-term market testing. Buying products with low quality and no after-sales service at low prices will have a great negative impact on the processing of enterprises.

6. After-sales service

Each manufacturer’s after-sales service is different, and the warranty period varies. For machines and laser software, there must be a professional training system to help customers get started as soon as possible. No matter how well a metal fiber laser cutting machine is done, it will encounter various problems in the process of use. If a customer encounters a problem that cannot be solved, it is particularly important that the manufacturer can provide a solution in time, so This is also an important factor to consider when purchasing a metal fiber laser cutting machine.

Nowadays, there are more and more domestic companies producing metal fiber laser cutting machines. When choosing equipment to purchase, you must conduct field inspections based on your own needs and the laser equipment produced by the company with the above points, and choose the most cost-effective and most suitable one. Metal fiber laser cutting machine.