Description

Y27 series 500 ton 630 ton 800 ton three-beam four-column deep drawing hydraulic press machines

Product introduction:

Y27 series 500 ton 630 ton 800 ton three-beam four-column deep drawing hydraulic press machines body adopts three-beam four-column structure. Rack accuracy is adjusted by adjusting nut

Features: ★Mechanical part:

- Y27 series 500 ton 630 ton 800 ton three-beam four-column deep drawing hydraulic press machinesbody adopts three-beam four-column structure. The upper beam, middle sliding beam and worktable are combined into a fixed machine through the column, the fastening nut and the adjusting nut. Rack, the rack precision is adjusted by adjusting nut, and has good strength, rigidity and precision retention.

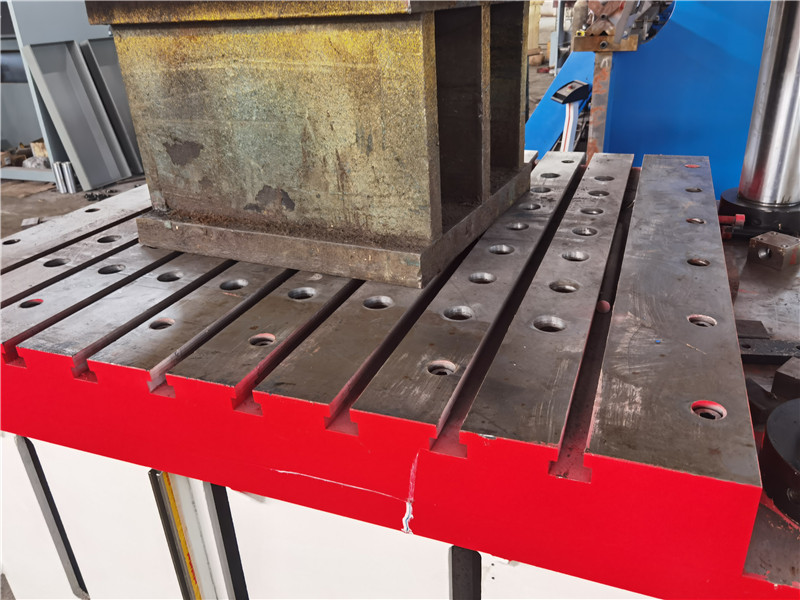

- Large parts such as upper beam, worktable and slider are steel plate welded parts, and the material is high-quality steel. The computer-optimized design meets the requirements of strength and rigidity. Carbon dioxide gas shielded welding and manual arc welding are used for welding and tempering. Treatment, eliminate internal stress, the lower plane of the slider and the upper plane of the worktable are machined with “T” grooves to fix the mold.

- Oil cylinder; the main oil cylinder is arranged along the center line of the upper sliding beam, the oil cylinder is fastened in the upper beam hole by the cylinder shoulder and the lock nut, the lower end of the piston rod of the master cylinder is fastened with the flange and the slider, and the oil cylinder is sealed with high quality pieces. The piston rod is made of high-quality carbon structural forged steel material, and the surface of the piston rod is plated with hard chrome, which is wear-resistant, long-life and durable.

- Column: The material is 45# steel, quenched and tempered, surface quenched, the hardness is HRC45-55, the surface is plated with hard chrome, and the wear resistance is increased. The nut material is 45# forged steel, which matches the thread on the column. Lock Tight body.

- Limit device: It is located on the right side of the host body. The non-contact proximity switch controls the upper and lower limit positions. Adjusting the upper and lower limit switches means adjusting the up and down movement position of the slider.

Optional accessories:

⑴ punching buffer device

⑵ Mobile workbench

⑶ light curtain safety protection device

⑷ Cooling device

⑸ There are floating guide rails and rolling brackets for changing molds

⑹ Touch mode industrial display

⑺ Feeding device (hydraulic and mechanical)

⑻ Work light

⑼ PLC programmable control system

★Hydraulic system:

- Y27 series 500 ton 630 ton 800 ton three-beam four-column deep drawing hydraulic press machineshas independent hydraulic power mechanism, which is composed of pump, motor, valve manifold, fuel tank, etc. The power mechanism includes oil filtration, liquid level display, etc. Various devices. The design of the hydraulic control system is reasonable, safe and easy to operate, and the advanced control method is adopted.

- The hydraulic system adopts a two-way cartridge valve; it has the characteristics of small size, compact structure, small flow resistance, large flow rate, sensitive action, reliable operation, good sealing performance, convenient maintenance and long service life.

- The main oil pump is a YCYI4-IB plunger pump, which changes with the pressure.

- The fuel tank is a welded steel plate, and the leakage test is qualified after welding. There is a cleaning window on the side of the fuel tank. Equipped with oil mark and adopts closed structure.

- The main hydraulic pipelines are connected by flanges and equipped with anti-vibration pipe clamps with reasonable layout to prevent vibration and leakage of high-pressure pipelines. Before installation, the pipelines are pickled and passivated to ensure the cleanliness of the oil.

- Pressure gauge: This machine uses an anti-seismic pressure gauge, which is not easy to be damaged.

- Pressure safety: The cartridge valve has its own pressure adjustment system. The pressure exceeds the set value and overflows back to the oil, so that the system is always kept within the set pressure and achieves overpressure protection.

- Oil filter: The oil is filtered through the oil filter and enters the two-way cartridge valve and enters the A cavity to better maintain the cleanliness of the oil.

- Cooling system: water-cooled circulating cooling device is adopted.

★Electrical system

- The Y27 series 500t 630t 800t three-beam four-column deep drawing hydraulic press machinesis equipped with an independent electrical control cabinet. The electrical control system part adopts PLC touch control, and the electrical control system part can realize two process methods of fixed stroke and constant pressure , The working pressure of the press liquid and the stroke of the slider can be adjusted according to the needs of the process, and it has the function of maintaining pressure.

- The machine adopts three-phase four-wire system, the three-phase AC power supply voltage is 380V/50HZ, the control circuit is AC 220V, and the solenoid valve control power supply is AC 220V.

- The main circuit is equipped with a circuit breaker, which can protect against overcurrent and short circuit, and a thermal overload protector, which can protect the motor from overloading.

★Operating system

- Manual, semi-automatic and fully automatic operation modes can be realized.

- Adjustment (jogging); Y27 series 500 ton 630 ton 800 ton three-beam and four-column deep drawing hydraulic press machineses operate the corresponding function buttons to complete the corresponding actions, each time the button is pressed to complete a jog of the corresponding action, mainly used for equipment When adjusting and changing molds.

This series of hydraulic press machineses are suitable for the pressing process of plastic materials, such as stamping and bending, flanging, sheet stretching, etc. In addition, it can also be used for calibration, press-fitting, powder product molding and non-metallic material pressing. This series of Y27 series 500 ton 630 ton 800 ton three-beam four-column deep drawing hydraulic press machines has two electrical control systems: relay control and PLC control. There are three operation modes: adjustment, manual and semi-automatic, which can realize constant pressure and fixed stroke. process method. During constant pressure forming, after pressing, there are pressure holding time delay and automatic return action. There is an ejector device in the middle of the worktable, which can also be used as a hydraulic pad for the forming process of reverse-stretching parts in addition to ejecting products. Its working pressure and stroke can be adjusted within the specified range according to the needs of the process.

The working pressure, pressing speed and stroke range of the Y27 series 500 ton 630 ton 800 ton three-beam four-column deep drawing hydraulic press machines products can be adjusted within the specified range according to the process needs, and two process modes of constant pressure and fixed stroke can be realized. During constant pressure forming, there is a pressure holding delay and automatic return after pressing. The middle of the worktable is equipped with an ejector device, which can be used as a hydraulic pad for the forming process of the stretched part in addition to ejecting the product. (Optional PLC control, grating protection, mobile table device).

- Maintenance

⑴ This Y27 series 500 tons 630 tons 800 tons three beams and four columns deep drawing hydraulic machine oil must be strictly filtered before it can be injected into the oil tank, and the oil level cannot be lower than the oil mark indication.

(2) The oil tank should be cleaned and replaced with new oil every six months. The time for immediate oil replacement should not exceed three months. The oil can be re-filtered and used again.

(3) The guide bush of the movable beam and the column should be lubricated with oil regularly.

⑷ It is recommended to use N46 anti-wear hydraulic oil or N46 low condensation hydraulic oil.

⑸ The pressure gauge should be checked every six months.

⑹ When the machine is out of use for a long time, the machined surfaces should be cleaned and coated with anti-rust oil.

- Safety operating procedures

(1) Those who do not understand the structural performance and operating procedures of the Y27 series 500-ton 630-ton 800-ton three-beam four-column deep drawing hydraulic press machines should not start the machine without authorization.

(2) If the machine is found to have serious oil leakage or abnormal phenomena during work (unreliable action, loud noise, and vibration level), stop immediately to check and analyze the cause, and eliminate the fault. Do not emphasize the reason and make the machine run with illness.

(3) During the working process of the machine, it is not allowed to overhaul or adjust the mold.

⑷ Overload and partial load use are strictly prohibited.

⑸ Prohibit the use of over-travel and over-pressure of the oil cylinder.