Description

W12- four roller plate rolling machine 4 rolls Hydraulic Rolling Machine with Touch screen CNC Control

New Design 4 rolls Hydraulic Rolling Machine

Product Application:

Four-roll plate bending machine, due to its full-featured, high-precision, and easy-to-use operation, this device is the ideal contemporary CNC coiling device. It is the ideal model for rolling circular and arc-shaped workpieces in energy, transportation, petroleum, chemical, boiler, shipbuilding, hydropower, and metal structure industries.

W12- four roller plate rolling machine Configuration of Hydraulic Plate Rolling machine is follows:

Main electronic elements: Schneider made in France;

Axletree:Double-row self-aligning bearing from Germany

Main motor: Siemens Electrical made in Germany

Programmable logic controller PLC:OMRON products from Japan

Hydraulic system: Bosch – Rexroth made in Germany

Oill pump: Sunny from USA ;

Work Roller:Material of work roller with 42CrMo Alloy steel.

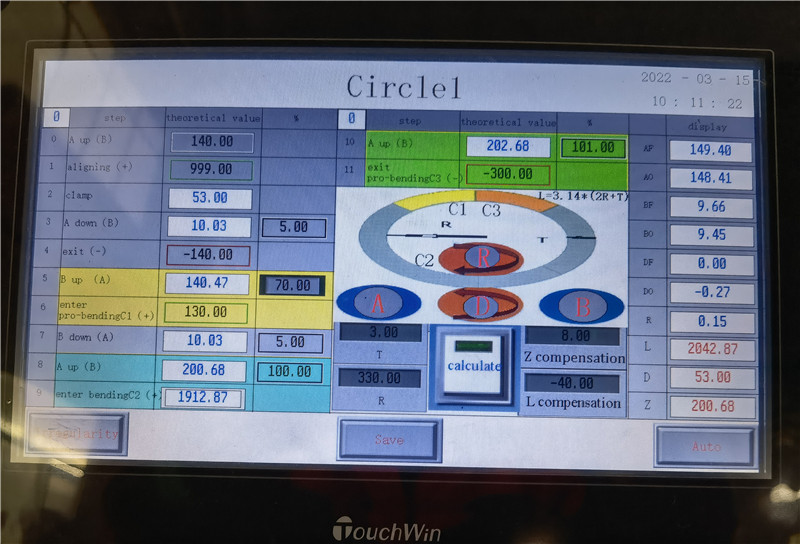

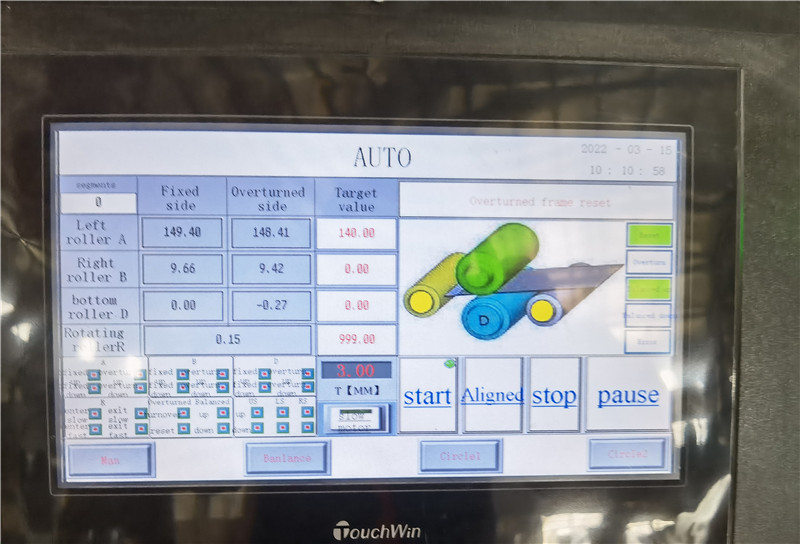

Digital display system:Touch Screen for Delta

Transducer:OMRON,Made in Japan

Automatic lubrication system:Sino-Japanese joint,which has block alarm

|

Model

|

Max bergulir ketebalan * panjang

|

Diameter Roll Utama

|

Diameter Sisi Roll

|

Bergulir Kecepatan

|

Motor utama

|

|

MM

|

MM

|

MM

|

M/min

|

KW

|

|

|

W12-4×1500

|

4×1500

|

140

|

120

|

4

|

2.2

|

|

W12-4×2000

|

4×2000

|

160

|

140

|

4

|

2.2

|

|

W12-4×2500

|

4×2500

|

190

|

150

|

4

|

3

|

|

W12-4×3000

|

4×3000

|

210

|

170

|

4

|

7.5

|

|

W12-4×4000

|

4×4000

|

270

|

210

|

4

|

5.5

|

|

W12-6×2000

|

6×2000

|

190

|

150

|

4

|

5.5

|

|

W12-6×2500

|

6X2500

|

210

|

170

|

4

|

7.5

|

|

W12-8×1500

|

8×1500

|

200

|

170

|

4

|

5.5

|

|

W12-8×2000

|

8×2000

|

210

|

180

|

4

|

7.5

|

|

W12-10X2000

|

10×2000

|

230

|

180

|

4

|

7.5

|

|

W12-10X2500

|

10×2500

|

270

|

210

|

4

|

11

|

|

W12-12×2000

|

12×2000

|

245

|

200

|

4

|

11

|

|

W12-12×2500

|

12×2500

|

265

|

220

|

4

|

11

|

|

W12-16×2000

|

16×2000

|

250

|

210

|

4

|

15

|

|

W12-16×2500

|

16×2500

|

300

|

240

|

4

|

15

|

|

W12-20×2000

|

20×2000

|

300

|

250

|

4

|

18.5

|

|

W12-20×2500

|

20×2500

|

350

|

280

|

4

|

18.5

|

|

W12-25X2000

|

25×2000

|

360

|

250

|

4

|

15

|

|

W12-25X2500

|

25×2500

|

390

|

300

|

4

|

18.5

|

|

W12-30×2500

|

30×2500

|

410

|

340

|

4

|

22

|

|

W12-30×3000

|

30×3000

|

450

|

380

|

4

|

30

|

|

W12-35×2000

|

35×2000

|

430

|

330

|

4

|

30

|

|

W12-35×2500

|

35×2500

|

460

|

360

|

4

|

30

|

|

W12-40×2500

|

40×2500

|

500

|

420

|

4

|

37

|

|

W12-40×3000

|

40×3000

|

540

|

440

|

4

|

45

|

|

W12-45×2500

|

45×2500

|

460

|

420

|

4

|

30

|

|

W12-45×3000

|

45×3000

|

510

|

460

|

4

|

37

|

|

W12-50×2500

|

50×2500

|

560

|

450

|

4

|

45

|

|

W12-50×3000

|

50×3000

|

600

|

480

|

4

|

55

|

|

W12-60×2500

|

60×2500

|

610

|

500

|

4

|

55

|

|

W12-60×3000

|

60×3000

|

650

|

520

|

4

|

75

|

|

W12-65×3000

|

65×3000

|

650

|

550

|

4

|

55

|

|

W12-85×3000

|

85×3000

|

760

|

680

|

4

|

75

|