Description

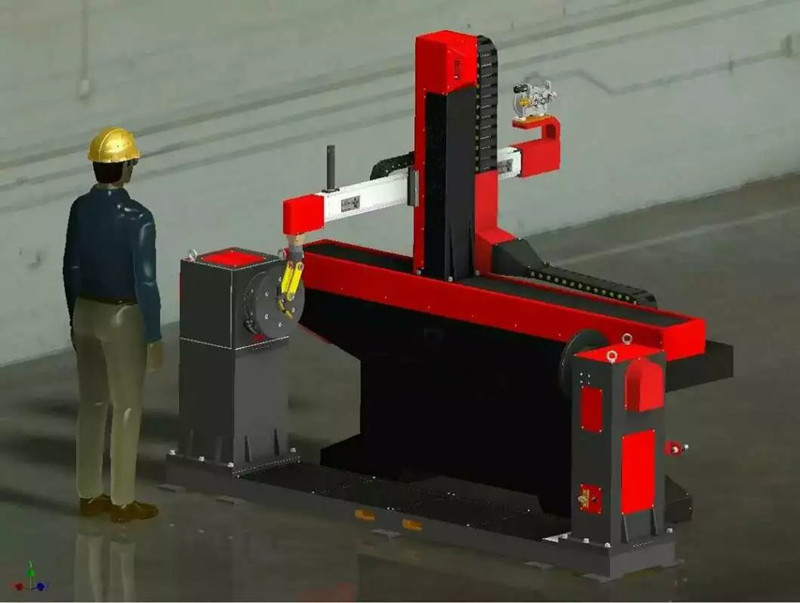

TIG or MIG 4 axis welding robot PM2500 with OTC Welding robots

Video in youtube:

Features:

- The system also controls the four servo axes at the same time movement; 2. Arc starting arc time precise control; 3. Welding start position can be precisely controlled;

- 4. According to the product of any programming; 5. Weld uniform beautiful fully.

The main technical parameters, Primapress can design robot according to customer requirement:

| X effective(mm) | 1700mm | 2500mm | 3000mm |

| Y effective(mm) | 800mm | 800mm | 800mm |

| Z effective(mm) | 500mm | 500mm | 500mm |

| R effective(mm) | 0-400 degree | 0-400 degree | 0-400 degree |

| MAX SPEED | 400mm/S or 24m/min | 400mm/S or 24m/min | 400mm/S or 24m/min |

| Repositioning accuracy | ±0.05mm | ±0.05mm | ±0.05mm |

| Programe | Teaching and manual | Teaching and manual | Teaching and manual |

| X、Y、Z、R motor | Taiwan Dongling Serbo | Taiwan Dongling Serbo | Taiwan Dongling Serbo |

| Transmission part | Taiwan TBI or HIWIN | Taiwan TBI or HIWIN | Taiwan TBI or HIWIN |

| Controller | 4 Axis movement ,scalable | 4 Axis movement ,scalable | 4 Axis movement ,scalable |

| Input and output | 24 input,12output,scalable | 24 input,12output,scalable | 24 input,12output,scalable |

| Programme storage | USB 30M | USB 30M | USB 30M |

| Main power | 220V 50HZ | 220V 50HZ | 220V 50HZ |

| Controller power | DC 24V | DC 24V | DC 24V |

| Welding way | MAG/MIG | MAG/MIG | MAG/MIG |

| Gas protection | CO2 or mixed gas | CO2 or mixed gas | CO2 or mixed gas |

| Size | 2.5×0.6*2.3m | 3.5*0.8*2.3m | 42*0.8*2.3m |

| Weight | 750KG | 950KG | 1250KG |

The whole module uses a walking mechanism:

1, linear guide + ball screw (Taiwan TBI),

2, electrical components (Schneider of France),

3, double valve solenoid valve (Taiwan Yadeke pneumatic hose (Japan), Yuan Long),

4, pneumatic components (Taiwan Yadeke),

5, cylinder (Taiwan Yadeke),

6, servo reducer (Taiwan East).

7, PLC (Korean LG),

8, intelligent man-machine interface touch screen (Wuxi xinje) .

Four-axis welding host description:

four-axis CNC welding host with X, Y, Z-axis linear motion and R-axis rotation movement, to achieve the welding of the linear line or curve movement and welding gun and workpiece welding angle adjustment. Thus completing the welding of various types of welding. X, Y, Z axis movement system using AC servo motor drive, ball screw drive, guide rail, to achieve the precise control of walking, R-axis AC servo motor drive, precision planetary reducer after the drive. Can accurately control the welding gun and the workpiece welding angle adjustment requirements, with X, Y, Z axis to achieve the completion of the welding process.

Four-axis motion control system features:

1.4 axis freedom degree space trajectory motion (straight line, arc, spiral curve). · Teaching track parameters, easy to operate, and support the teaching of graphics preview function, compared with the teaching of the document is consistent with the actual graphics.

- Can save multiple sets of welding process, 256M file storage space, the maximum storage 9999 processing files, each file can save up to 9999 file points. · Support AUTO CAD or Corel DRAW to convert PLT format graphics import function, simplify the teaching of complex graphics.

- Multiple I / O port arbitrary programming, to facilitate the full range of automated design. · Use the text file format to save the processing file, easy to modify through the computer. USB communication and RS232 communication interface, processing files can be downloaded directly through the U disk. · Single or automatic machining.

- During the welding process speed, acceleration, input and output ports can be flexible control adjustment. High precision welding, uniform track, welding stability, high efficiency. * The use of hardware interpolation, can achieve fast linear, circular interpolation and various complex trajectory movement.