Description

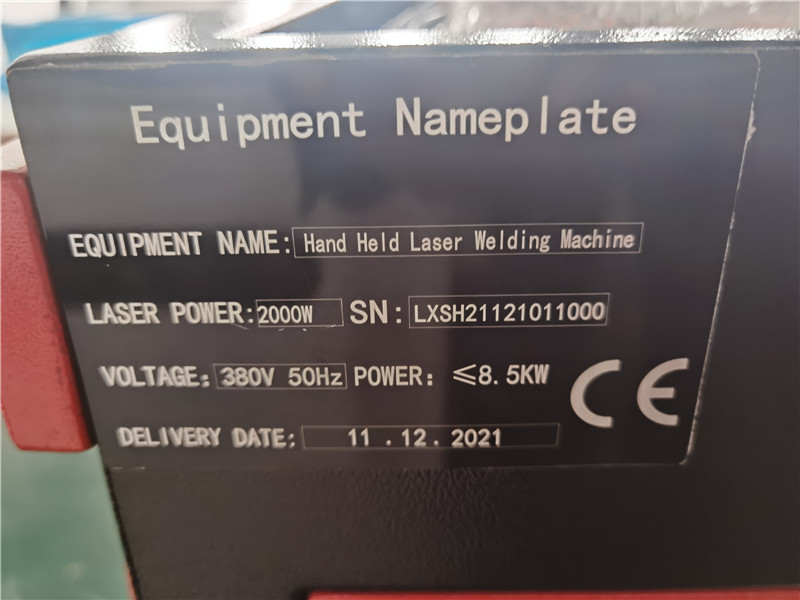

Stainless steel Hand laser welding machine aluminum portable metal fiber laser welding machine

Technical Specifications:

| Power / Material

Weld depth |

Stainless Steel | Mild steel | Galavinised Steel |

| Power / Material

Weld depth |

Stainless Steel | Mild steel | Galavinised Steel |

| 500W | 0.5-1mm | 0.5-1mm | 0.5-1mm |

| 750W | 0.5-1.7mm | 0.5-1.32mm | 0.5-1.2mm |

| 1000W | 0.5-2.7mm | 0.5-2.0mm | 0.5-2mm |

| 1500W | 0.5-3.6mm | 0.5-2.7mm | 0.5-2.8mm |

| 2000W | 0.5-4.6mm | 0.5-3.6mm | 0.5-3.5mm |

Model features:

★High energy density, low heat input, small amount of thermal deformation, and narrow melting depth in the heat and heat affected zone of the melting zone.

★The cooling rate is high, so that the weld structure can be fine and the joint performance is good.

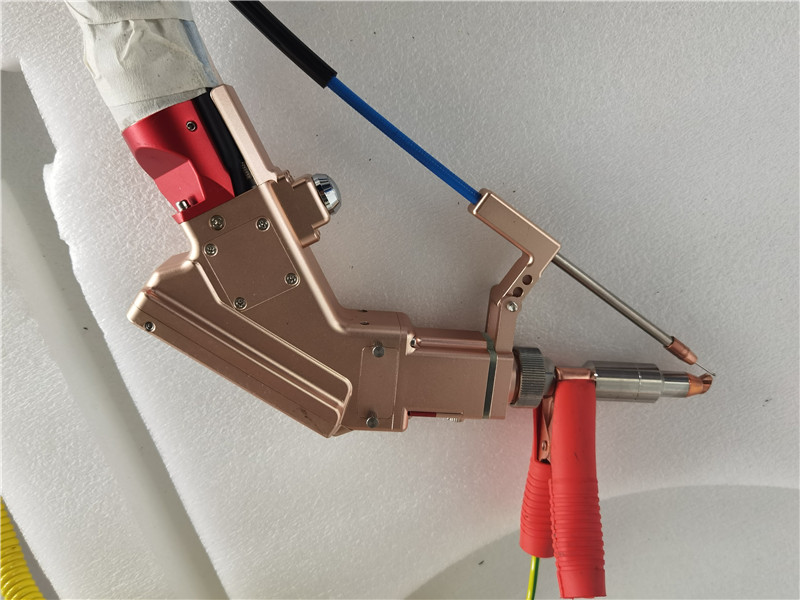

★ Compared with contact welding, laser welding eliminates the need for electrodes, reducing daily maintenance costs and greatly improving work efficiency.

★The weld is fine, the penetration is large, the taper is small, the precision is high, the appearance is smooth, flat and beautiful.

★ No consumables, small size, flexible processing, low operating and maintenance costs

★The laser is transmitted through the optical fiber and can work with the assembly line or the robot.

Product advantages:

The laser welding machine adopts 150-3000 watt fiber laser source, which has high photoelectric conversion efficiency and long life of 100,000 hours.

The energy provided by electric energy is 25%-30% converted into laser energy, and the photoelectric conversion rate is many times that of YAG laser.

Product Application :

This kind of machine is widely used in communications devices , IT ,medical , electronics , batteries tab-lead , fiber-optic coupling devices , CRT electronic gun , metal parts , cell phone vibrating motors , clocks precision parts , automotive sheet steel optical communications industry copper parts , aluminum parts etc precision welding .

welding results :

The welding seam is smooth and beautiful, the welding workpiece has no distortion, no welding scar, and the welding is firm and reduces the subsequent grinding process. Save time and cost.