Description

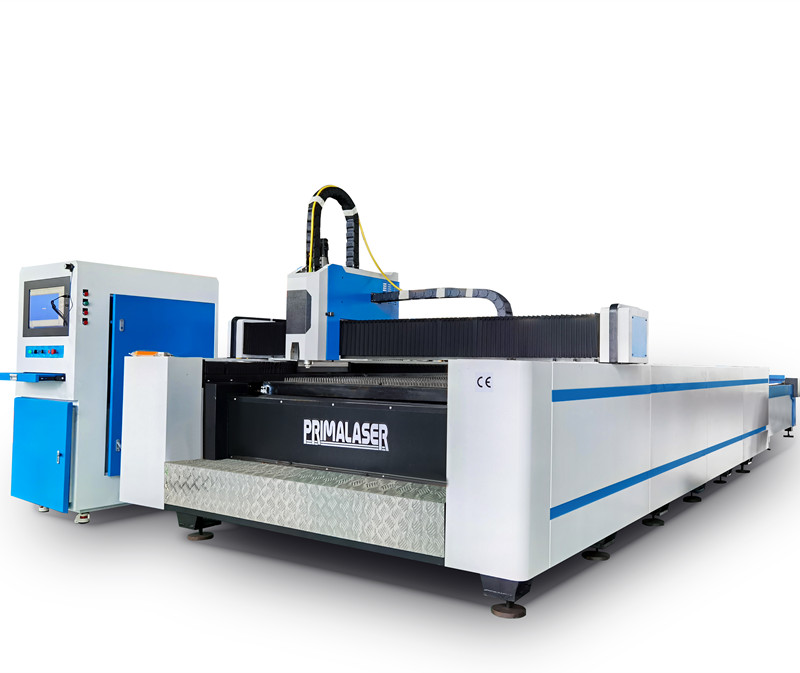

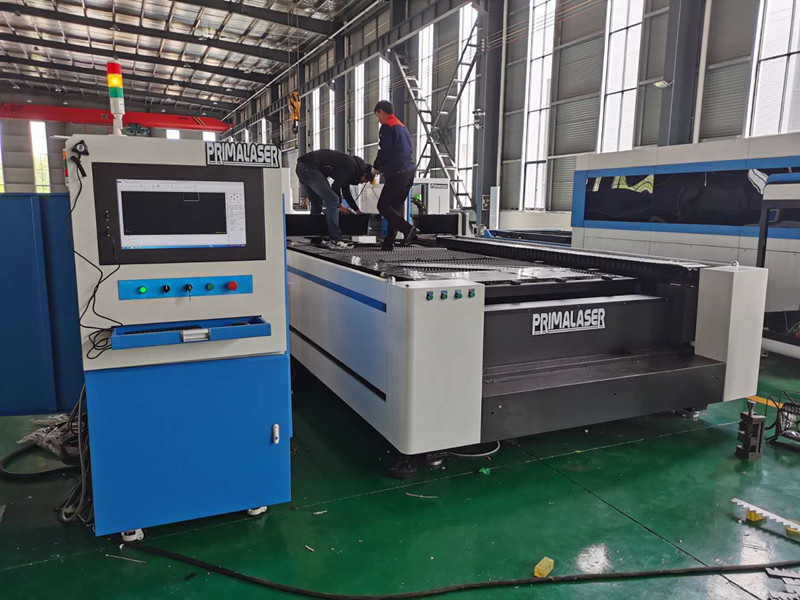

Shuttle Table fiber Laser Cutting Machine exchange table fiber laser cutting machine

Exchange table laser cutting machine will save metal sheet loading and unloading time, and safety for operators.

The machine power can be from 1000W~15000W, for metal sheet cutting thickness mild steel till 30mm, and stainless steel till 30mm

The advantages of our laser cutting machine Primalaser:

| 1. Air conditioner room: with all electrical parts and laser source inside, which will keep parts working stably even

24hours continued working, prolong lifetime of electrical parts, dust isolation

2. All machine tested by interferometer, to ensure the machine accuracy

3. Exchange table, frame with copper protection cover to protect the frame welded to machine main body not burned during cutting (for more than 2Kw) |

| 4. Monitor: during cutting it’ll monitor inside of cover enclosure for operator’s safety

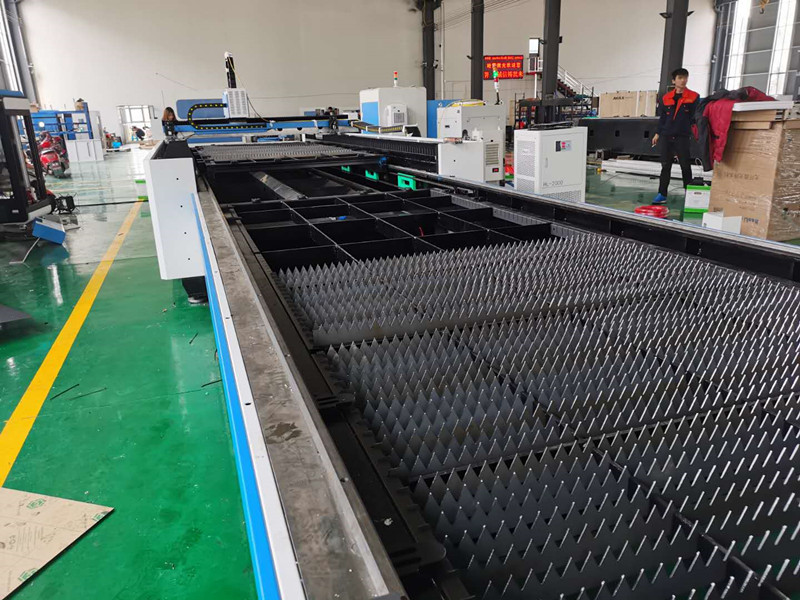

5. All table frames are produced by our own factory, strictly controlled, and tempered

6. Cylinder controlled by solenoid, segmented dedusting |

Product Details

The advantages of our laser cutting machine

| 1. Air conditioner room: with all electrical parts and laser source inside, which will keep parts working stably even 24hours continued working, prolong lifetime of electrical parts, dust isolation

2. All machine tested by interferometer, to ensure the machine accuracy

3. Exchange table, frame with copper protection cover to protect the frame welded to machine main body not burned during cutting (for more than 2Kw) |

| 4. Monitor: during cutting it’ll monitor inside of cover enclosure for operator’s safety

5. All table frames are produced by our own factory, strictly controlled, and tempered

6. Cylinder controlled by solenoid, segmented dedusting

|

Technical Parameter

| (一)、Main Electrical Collocation | ||

| Part Name & Descriptions | remark | |

| 3000W Laser Generator | IPG(German) | German Brand |

| Optical system | Import Media diaphragm | UK |

| Laser cutting head | Quelle with Auto focus

Precitec(German brand) autofocus Optional |

|

| Reducer | Shimpo | Japan |

| Water chiller | Over-flow protection, temperature stability ± 0.5 ℃, green two-cycle water-cooled machine, titanium evaporation control cold | Wuhan, China |

| Mechanical driving system | Rack and Pinion

Bevel type, Atlanta |

German |

| Button Module | Schneider | German |

| AC Contactor | Schneider | German |

| Solenoid Valve | Airtec | Taiwan |

| High precision auto-sensor | Accuracy ±0.1mm | China |

| PC System | Industrial control | EVOC, Taiwan |

| X axis servo unit | 2.2Kw servo single driving | Yaskawa, Japan |

| Y axis servo unit | 4.4Kw*2 servo dual driving | Yaskawa, Japan |

| Z axis servo unit | 750W for head with auto focus | Yaskawa or Fuji, Japan |

| Electric Proportion | Schneider | German |

| Cutting Software | Cypcut (loop model)

(support English language, file formate .dxf, PLT, Gerber, AI and so on) |

Shanghai, China |

| Table | 1. Extruded aluminum gantry beam

2. Strictly make table with hardening, tempering treatment to ensure no deformation during long time production Body welded sheet thickness 16mm for 2060 |

Primapress, China |

| Technical Parameter | ||

| 1 | Laser Wavelength | 1070nm |

| 2 | Maximum Power | 3000W |

| 3 | Accelaration | 1.5G |

| 4 | Power Consumption | 30Kw |

| 5 | Max Speed | 170m/min(complex speed), 120m/m(single axis) |

| 6 | Min Linewidth | 0.15mm (for materials with thickness less than 0.4mm), depends on the sheet thickness |

| 7 | Cutting Thickness | MS: max 22mm, mass production 18mm; SS: max 12mm, mass production 10mm;

|

| 8 | Max.Cutting Dimension | Exchange Table

1500*3000mm 1500*6000mm 2000*4000mm 2000*6000mm 2500*6000mm 2000*6500mm 2500*8000mm(Fargo solution) |

| 9 | Cutting Table Mechanical Accuracy: ±0.05mm | |

| 10 | X,Y,Z Repeated Positioning Precision:±0.02mm | |

| 11 | Power Supply:Three-phase 5 wires AC 380V±5%,50Hz±1% | |

Cutting Parameter List

| Material | thickness/mm | speed mm/s | Focus | Pressure | Nozzle | Power | Gas |

| SS | 1 | 800 | 0 | 1.2Mpa | 2.0单 | 100% | N2 |

| 2 | 300 | 0.5 | 1.6Mpa | 2.0单 | |||

| 3 | 130 | 2 | 1.8Mpa | 2.0单 | |||

| 4 | 80 | 3 | 2.4Mpa | 3.0单 | |||

| 5 | 60 | 3.5 | 2.4Mpa | 3.0单 | |||

| 6 | 40 | 4 | 2.4Mpa | 4.0单 | |||

| 8 | 25 | 4.5 | 2.4Mpa | 4.0单 | |||

| 10 | 18 | 7 | 2.4Mpa | 4.0单 | |||

| 1 | 600 | 0 | 9bar | 1.0双 | 60% | O2 | |

| 2 | 160 | -4 | 8bra | 1.0双 | |||

| 3 | 100 | -5 | 4bar | 1.5双 | |||

| 4 | 80 | -4 | 4bar | 1.5双 | |||

| 5 | 50 | -6 | 4bar | 1.5双 | |||

| 6 | 30 | -6 | 1.5bar | 1.5双 | |||

| 8 | 20 | -6 | 0.6bar | 1.5双 | |||

| 10 | 15 | -6 | 0.6bar | 1.5双 | |||

| 12 | 12 | -6 | 0.6bar | 1.5双 | |||

| Brass | 1 | 400 | 1.5 | 1.2Mpa | 2.0单 | 100% | N2 |

| 2 | 200 | 1.5 | 1.6Mpa | 2.0单 | |||

| 3 | 100 | 3 | 1.6Mpa | 2.0单 | |||

| 4 | 60 | 3.5 | 1.8Mpa | 2.0单 | |||

| 5 | 40 | 3 | 1.8Mpa | 3.0单 | |||

| 6 | 30 | 4.5 | 2.0Mpa | 3.0单 | |||

| 8 | 10 | 4.5 | 2.4Mpa | 3.0单 | |||

| Al. | 1 | 700 | 0 | 1.2Mpa | 2.0单 | ||

| 1.5 | 450 | 0 | 1.4Mpa | 2.0单 | |||

| 2 | 330 | 0.5 | 1.6Mpa | 2.0单 | |||

| 3 | 150 | 1 | 1.8Mpa | 2.0单 | |||

| 4 | 60 | 2 | 1.8Mpa | 3.0单 | |||

| 5 | 45 | 2.5 | 2.0Mpa | 3.0单 | |||

| 6 | 35 | 2.5 | 2.4Mpa | 3.0单 | |||

| 8 | 15 | 3.5 | 2.4Mpa | 3.0单 | |||

| 10 | 10 | 4 | 2.4Mpa | 4.0单 | |||

| 12 | 8 | 5 | 2.4Mpa | 4.0单 | |||

| CS | 1 | 150 | -0.5 | 9bar | 2.0双 | 33% | O2 |

| 2 | 100 | -2.5 | 5bar | 2.0双 | 35% | ||

| 3 | 70 | -3 | 1bar | 1.0双 | 90% | ||

| 4 | 55 | -3 | 1bar | 1.0双 | 90% | ||

| 5 | 50 | -2.5 | 1bar | 1.0双 | 60% | ||

| 6 | 40 | -3 | 1bar | 1.0双 | 98% | ||

| 8 | 20 | -3 | 0.6bar | 2.0双 | 60% | ||

| 8 | 36 | -3 | 0.8bar | 1.2双 | 100% | ||

| 10 | 18 | -3 | 0.6bar | 3.0双 | 50% | ||

| 12 | 15 | -3 | 0.6bar | 3.0双 | 50% | ||

| 14 | 15 | -3 | 0.8bar | 3.0双 | 60% | ||

| 16 | 12 | -3 | 0.8bar | 3.0双 | 70% | ||

| 18 | 14 | -3.5 | 0.8bar | 4.5双 | 80% | ||

| 20 | 11 | -4 | 0.8bar | 4.5双 | 80% | ||

| 22 | 10 | -4 | 0.8bar | 4.5双 | 80% |

#sql fiber laser cutting machine #laser fiber cutting machine head

#fiber laser cutting machine 1kw #fiber laser cutting machine ipg2000w

#laser cutting machine 2000w fiber #fiber laser 2000watt cutting machine