Description

JM31/JMD31series gantry type single point press with high performance

Video link:

◆ Welded Steel plate framework with high intensity of machine body.

◆ Dry type friction clutch and brake,wet friction clutch and brake are optional for JM31-160~400 type.

◆ Equipped with hydraulic overload protecting device.

◆ Eight-side lengthened guide with high precision.

◆ Adopts electric shut height adjustment with digital display.

◆ Equipped with lifting balance cylinder.

◆ Duplex valves imported.

◆ Electric compelling grease lubrication system.

◆ Balancing cylinder adopts manual lubrication system.

◆ One set of blowing device.

◆ Controlled by PLC with international brand.

◆ Buttons, indicators, AC contactors, air circuit breakers and other controlling devices are imported from international brand.

◆ Electronic cam device with intelligent top dead center stop function and several safety function.

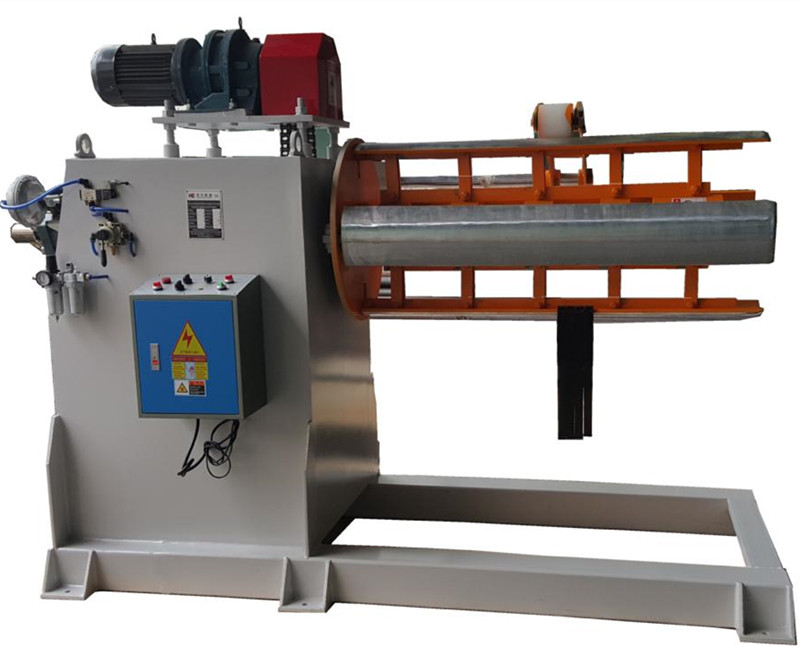

◆ Optional air cushion device, NC feeding machine, light curtain and inverter with international brand to fulfill stroke adjustment.

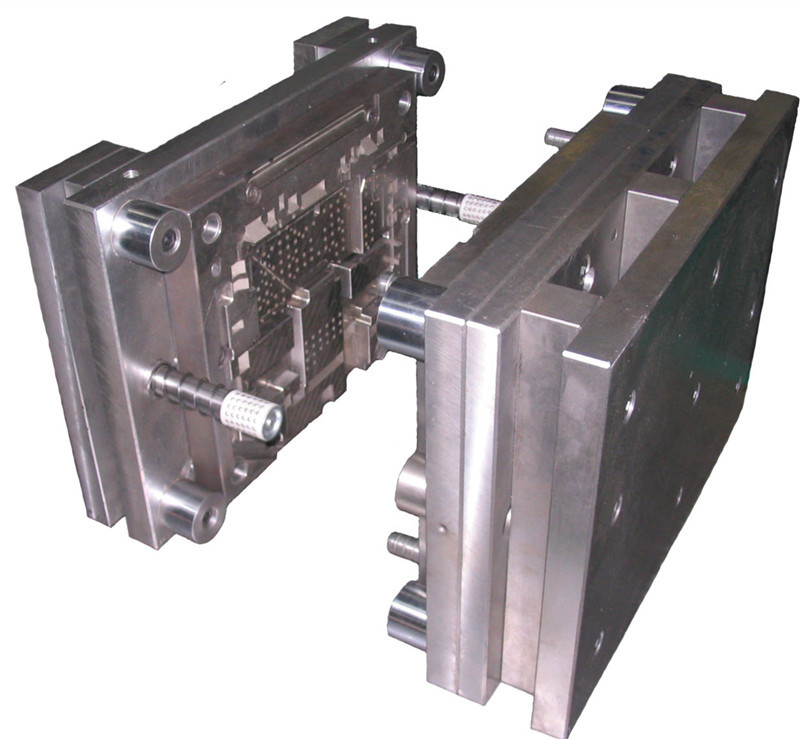

◆ JMD31 series equipped with multi pitmen framework, suitable for flat stretching.

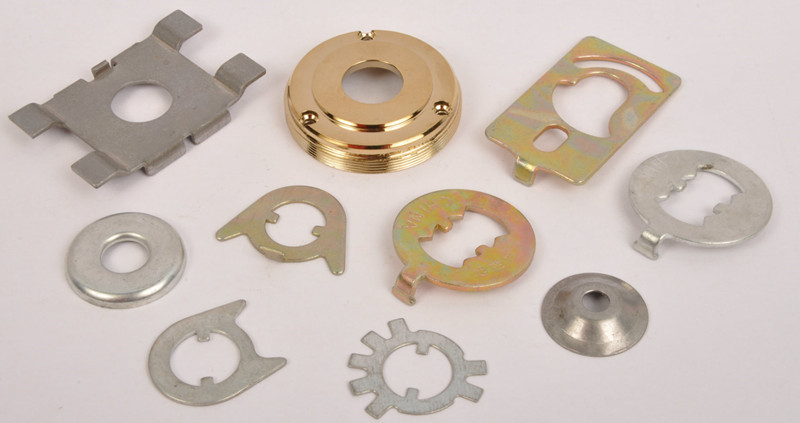

It is mainly for the high accuracy automatic punching line with progressiv die.

#punching machine hydraulic press # Pneumatic press Machine

#Press Machine

|

JM31-160 JMD31-160 |

JM31-200 JMD31-200 |

JM31-250 JMD31-250 |

JM31-315 JMD31-315 |

JM31-400 |

JM31-500 |

JM31-630 |

||||

|

Capacity |

kN |

1600 |

2000 |

2500 |

3150 |

4000 |

5000 |

6300 |

||

|

Nominal Stroke |

mm |

6 |

6 |

8 |

8 |

10 |

10 |

10 |

||

|

Slide Stroke |

mm |

160 |

180 |

200 |

200 |

200 |

200 |

250 |

||

|

SPM |

Fixed |

min-1 |

40 |

35 |

30 |

30 |

25 |

20 |

18 |

|

|

Variable |

35~50 |

30~40 |

25~35 |

25~35 |

20~30 |

/ |

/ |

|||

|

Max. Die Height |

mm |

350 |

450 |

500 |

550 |

600 |

650 |

700 |

||

|

Die Height Adjustment |

mm |

110 |

110 |

120 |

120 |

120 |

120 |

120 |

||

|

Bolster (FB×LR) |

mm |

740×1050 |

760×1130 |

800×1200 |

850×1250 |

900×1350 |

1000×1500 |

1200×1700 |

||

|

Bolster Thickness |

mm |

150 |

160 |

170 |

170 |

180 |

190 |

200 |

||

|

Slide Area (FB×LR) |

mm |

650×800 |

650×850 |

700×900 |

750×950 |

1050 |

900×1200 |

1100×1450 |

||

|

Shank Hole (Dia.×Dpth) |

mm |

φ65×90 |

φ65×90 |

φ70×90 |

φ70×90 |

φ80×90 |

φ80×90 |

φ90×100 |

||

|

Between Columns |

mm |

1150 |

1200 |

1320 |

1370 |

1550 |

1700 |

1900 |

||

|

Side Opening (FB×H) (Up Bolster) |

mm |

760×300 |

800×370 |

820×430 |

880×480 |

920×520 |

1020×600 |

1100×650 |

||

|

Between Up Bolster & Floor |

mm |

1020 |

1030 |

1050 |

1050 |

1050 |

1060 |

1050 |

||

|

Main Motor Power |

kW |

15 |

18.5 |

22 |

30 |

37 |

45 |

75 |

||

|

Cushion (Option) |

Qty. |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

||

|

Ejecting Force |

kN |

160 |

160 |

250 |

250 |

250 |

250 |

250 |

||

|

Ejecting Stroke |

mm |

80 |

80 |

80 |

80 |

80 |

80 |

80 |

||

|

Ejecting Area |

mm |

φ350 |

φ350 |

340×540 |

400×540 |

400×540 |

400×540 |

400×540 |

||

|

Outline Size (FB×LR×H) |

mm |

2480×1750×3500 |

2570×1810×3610 |

2950×2080×3850 |

3150×2200×4000 |

3430×2400×2410 |

3670×2580×4600 |

4150×2900×5200 |

||

|

Net Weight |

kg |

16500 |

19500 |

24000 |

29000 |

37000 |

48000 |

62500 |

||