Description

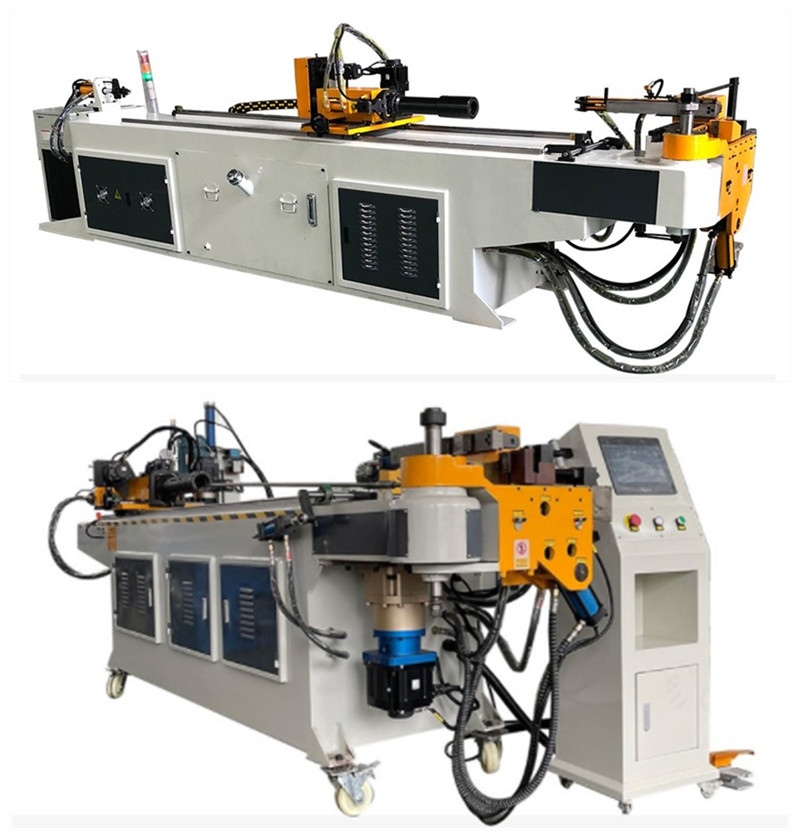

Hydraulic 3D CNC Tube Bender,Wheel Barrow Full Automatic CNC Tube and Pipe Bending Machine DW38CNC-2A1S

Brief Introduction on Pipe Bending Machine

Full-automatic pipe bending machine equipped with PLC or IPC which manage Bending (Y), Feeding (X) & Rotation (Z) in a complete automatic cycle.

Bending (Y-Axis): Controlled by Servomotor or by Hydraulic.

Feeding (X-Axis): Controlled by Servomotor.

Rotating (Z-Axis): Controlled by Servomotor.

We only use popular quality components in the production of our benders from such companies as JAPAN MITSUBISHI,TAIWAN WEINVIEW,

JAPAN YUKEN,JAPAN NEIMICOM,SKF AND ETC…

This value priced CNC Tube Bending Machine is an excellent choice for general purpose and any type of conventional tube bending applications.

Technical features:

1. Bending Servo Motor-Bending controlled by electric. We can make pipe bending machine that bending controlled by hydraulic or electric which based on your requirement.—–pipe tube bender | bending machine

2.Tooling Set-The whole tooling set including: Bending die,Clamp die,Pressure Die,Collet(CNC),Mandrel(optional),Wiper die(optional).—–pipe tube bender | bending machine

Features on Pipe Bending Machine

- Interactive PLC touch screen offers easy access to auto and manual operating modes…-(Pipe Curving Folding Machine)

- System diagnostics and multiple language capability…-(Pipe Curving Folding Machine)

- Standard clockwise bending direction…-(Pipe Curving Folding Machine)

- Fully hydraulic clamping on clamp die and pressure die.—–(Pipe Curving Folding Machine)

- Drop-way hydraulic clamping.——(Pipe Curving Folding Machine)

- Direct acting hydraulic pressure die with adjustable speed valve.–(Pipe Curving Folding)

- Maximum 100 sets of program storage,Maximum 32 bends for each program.

- With Independent programmable speeds Y, B, and C axes.—(Pipe Curving Folding Machine)

- Programmable material spring back settings for each bend angle.—(Pipe Curving Folding Machine)

- Automatic release of tube prior to final bend.–(Pipe Curving Folding Machine)

- Bending Axis-Driven by Cylinder,Feeding Axis-Driven by Servo Motor,Rotating Axis-Driven by Servo Motor.—(Pipe Curving Folding Machine)

- Obtain quality repeatable bends in steel, stainless, aluminum, titanium and brass.—(Pipe Curving Folding Machine)

- Foot Pedal Cycle start.–(Pipe Curving Folding Machine)

- With Air Cooling System or water cooling system.—-(Pipe Curving Folding Machine)

- One set of Tooling for Draw Bending.–(Pipe Curving Folding Machine)

- Wiper die Bracket.–(Pipe Curving Folding Machine)

- 1 Mandrel Rod.—(Pipe Curving Folding Machine)

- Operation and Maintenance Manual.—(Pipe Curving Folding Machine)

- Tool Box with Adjusted Tools.—(Pipe Curving Folding Machine)

- Electric: As required (3 phase 220V or 380V or 415V…)—-(Pipe Curving Folding Machine)

Optional

- Industrial Computer Controlling———————-(Pipe Curving Folding Machine)

- Anticipate Mandrel Extraction————————(Pipe Curving Folding Machine)

- Automatic mandrel/machine lubrication————(Pipe Curving Folding Machine)

- Anti-clockwise bending direction———————(Pipe Curving Folding Machine)

- Machine effective length over mandrel —————-(Pipe Curving Folding Machine)

- Safety Mat————————————————–(Pipe Curving Folding Machine)technical parameter for choice:

Model DW18CNC-2A1S DW25CNC-2A1S DW38CNC-2A1S DW50CNC-2A1S DW63CNC-2A1S DW75CNC-2A1S DW89CNC-2A1S DW114CNC-2A1S Maximum pipe diameter × wall thickness Φ19×1.5 Φ25×1.8 Φ38×2.0 Φ51×2.0 Φ63×2.5 Φ76×3.0 Φ89×3.0 Φ114×8.0 Standard feeding distance 1200mm 1800mm 2200mm 2500mm 2500mm 2600mm 3200mm 3600mm Feed type Straight feeding or jig Straight feeding or jig Straight feeding or jig Straight feeding or jig Straight feeding or jig Straight feeding or jig Straight feeding or jig Straight feeding or jig Maximum bending radius 90mm 120mm 175mm 200mm 250mm 300mm 350mm 400mm Maximum angel of bending 185° 185° 185° 185° 185° 185° 185° 185° Numbers of single pipe bends 16 16 16 16 16 16 16 16 Numbers of parts saved 400sets 400sets 400sets 400sets 400sets 400sets 400sets 400sets Rotation pace Max.270°/s Max.270°/s Max.270°/s Max.270°/s Max.270°/s Max.180°/s Max.180°/s Max.180°/s Feeding pace Max.1000mm/s Max.1000mm/s Max.900mm/s Max.900mm/s Max.900mm/s Max.700mm/s Max.700mm/s Max.700mm/s Rotation accuracy ±0.15° ±0.15° ±0.15° ±0.15° ±0.15° ±0.15° ±0.15° ±0.15° Feeding accuracy ±0.1mm ±0.1mm ±0.1mm ±0.1mm ±0.1mm ±0.1mm ±0.1mm ±0.1mm Rotation servo power 400W 400W 400W 750W 750W 1KW 1KW 1.5W Feeding servo power 750W 1KW 1KW 1KW 1.5W 2KW 2KW 3.5W Oil pressure motor power 3KW 3KW 4KW 5.5KW 5.5KW 7.5KW 11KW 15KW Total weight 1200KG 1350KG 2000KG 2500KG 2800KG 3600KG 4000KG 5000KG boundary dimension(mm) 2760×690×1000 3000×780×1100 3400×780×1160 4200×850×1160 4300×850×1160 5700×1080×1400