Description

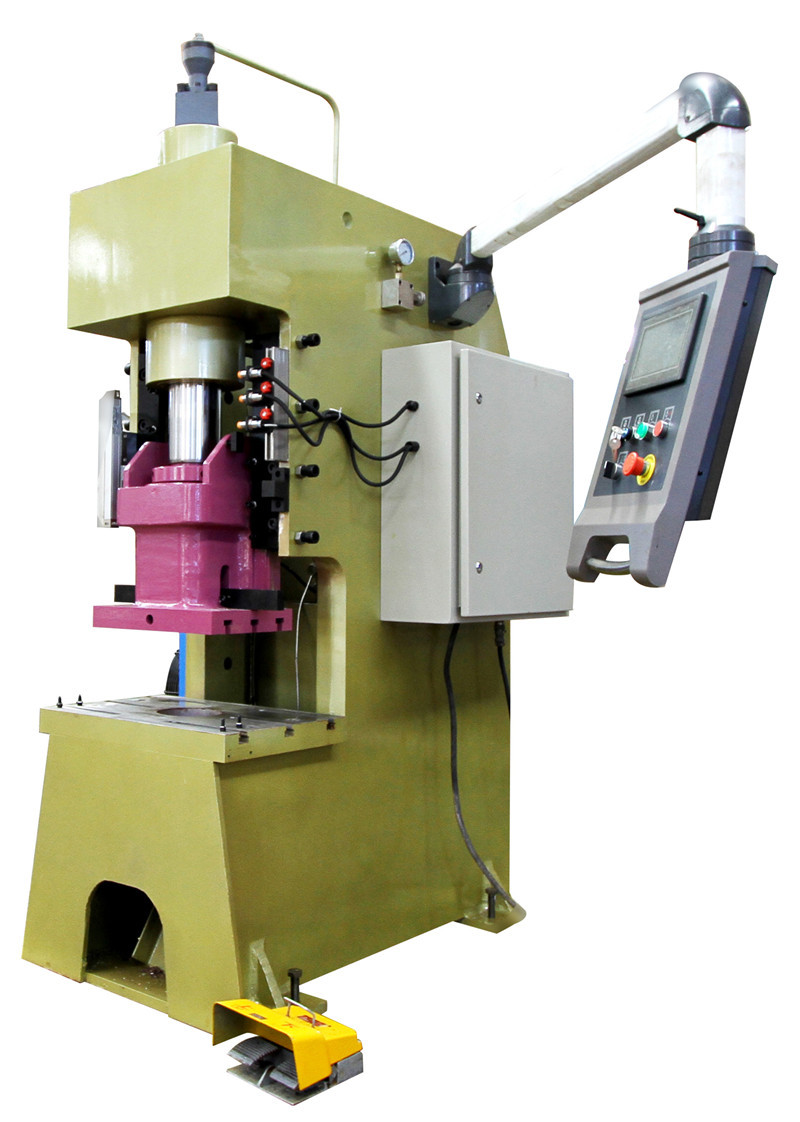

High speed deep drawing Hydraulic press machine, single column hydraulic press

Video link:

Performance, Features Overview:

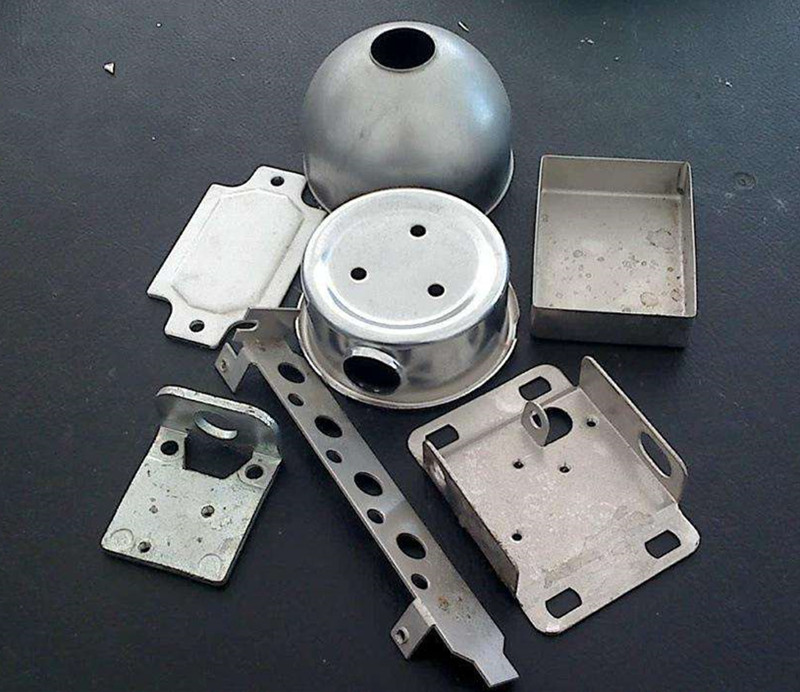

CNC hydraulic press is a replacement for mechanical punch, which combines the advantages of punch and single column hydraulic press. Can be punching, cutting angle, cutting, pressing, can also do stretching, forming. Truly realized a machine multi-purpose.

CNC hydraulic presses used plc centralized control, full touch screen operation. Can be manual and automatic free control, the machine running more stable, low noise, high precision. The hazard coefficient is zero.

If coupled with automatic feeding without manual operation, the real realization of a multi-machine operation, but also network using computer remote operation.

Equipment All technology is used program operation, travel, speed, pressure, stretching, the number of times, without manual adjustment.

Applicable to the following:

Automotive metallurgy aviation ship daily hardware household appliances building materials LED lighting screen punching signs

Accessories: pressure display, counting display, travel display, speed display, time display, fault display

Action sequence: ordinary punch use

Fast down — pressure punching – quick return — restore far point

Ordinary press used

Fast down —- fast turn slowly —- start to suppress — packing —– fast return —- restore the origin .

Technical Specifications:

| Model | 25T | 40T | 63T | 80T | 100T | 125T | 160T | 200T | 250T | 315T | 400T | |

| Force KN | 250 | 400 | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3150 | 4000 | |

| Stroke mm | 10-100 | 10-120 | 10-120 | 10-140 | 10-150 | 10-150 | 10-180 | 10-200 | 10-200 | 10-200 | 10-200 | |

| Max stroke mm | 120 | 120 | 130 | 140 | 180 | 180 | 180 | 200 | 200 | 200 | 200 | |

| Mold adding height mm | 100-200 | 140-200 | 160-270 | 180-280 | 200-320 | 220-320 | 260-420 | 280-430 | 280-440 | 300-480 | 350-500 | |

| Stroke times l/min | 40-70 | 30-65 | 30-60 | 30-60 | 20-50 | 20-50 | 20-50 | 20-45 | 20-45 | 20-35 | 18-30 | |

| Air force Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | |

| Down speed m/s | 225 | 230 | 220 | 220 | 210 | 250 | 230 | 240 | 240 | 240 | 230 | |

| Work speed m/s | 10 | 10 | 8 | 8 | 8 | 8 | 8 | 8 | 6 | 6 | 5 | |

| Back speed m/s | 180 | 180 | 180 | 160 | 160 | 150 | 150 | 140 | 130 | 130 | 130 | |

| Worktable | L-R | 500 | 590 | 650 | 760 | 820 | 840 | 940 | 940 | 1000 | 1100 | 1100 |

| F-B | 390 | 440 | 450 | 500 | 580 | 580 | 700 | 750 | 800 | 900 | 1000 | |

| Hole | 100 | 150 | 150 | 180 | 180 | 200 | 220 | 250 | 250 | 300 | 300 | |

| Throat depth | 200 | 250 | 260 | 260 | 300 | 310 | 380 | 400 | 400 | 450 | 500 | |

| Stroke | L-R | 220 | 280 | 320 | 560 | 400 | 400 | 420 | 600 | 700 | 800 | 840 |

| Mold bar | 40 | 50 | 50 | 60 | 60 | 60 | 70 | 70 | 70 | 80 | 80 | |

| Hole | 330 | 440 | 320 | 350 | 610 | 610 | 720 | 720 | 800 | 900 | 920 | |

| Worktable height mm | 500 | 550 | 550 | 600 | 660 | 680 | 700 | 750 | 750 | 800 | 840 | |

| Motor KV | 5.5 | 5.5 | 5.5 | 7.5 | 11 | 11 | 15 | 15 | 22 | 30 | 37 | |

| Dimensions | L-R | 1100 | 1100 | 1250 | 1370 | 1350 | 1600 | 1700 | 1800 | 1900 | 2000 | 2200 |

| F-B | 1150 | 1260 | 1450 | 1630 | 1630 | 1850 | 2000 | 2100 | 2200 | 2300 | 2500 | |

| Height | 1800 | 1960 | 2270 | 2500 | 2600 | 3400 | 3500 | 3600 | 3750 | 3900 | 4000 | |

| NotesL we can costomerise the request,including stroke, throat depth,and cushion device and so on. | ||||||||||||