Description

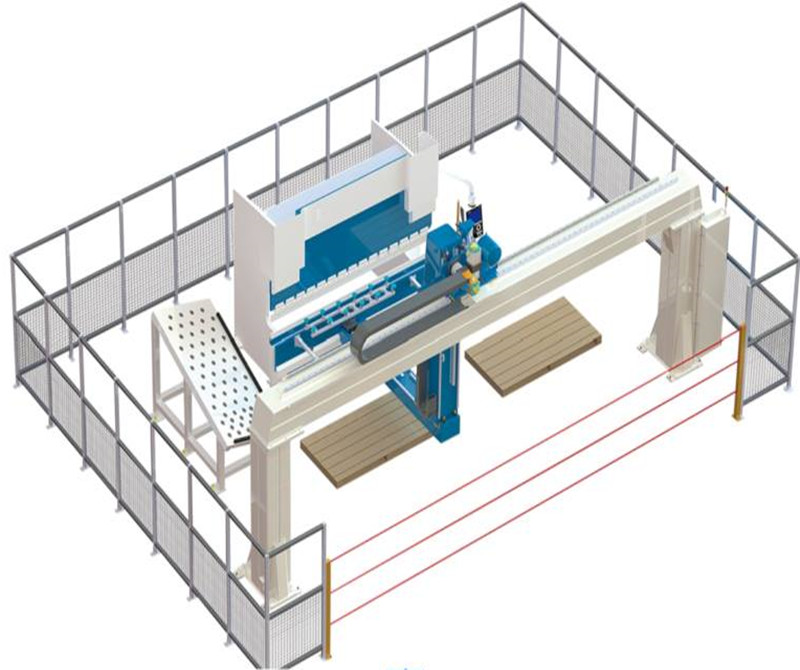

Gantry style 5-axis cnc press brake robot bending/turret punch press machine

The Gantry Style

The Gantry Style

The Gantry Style 5-axis CNC Robot Bending and CNC Turret Punch Press with the AP-50 load/unload automation system with part picking and stacking eliminates all manual sheet handling.

One of the most flexible automation systems available for punching & bending. The AP-50 system can handle small and large volume applications with common material type, thickness and size and small as well as large work pieces. AP-50 offers advanced load/unload, part picking and a large area for stacking punched parts directly onto the allocated pallet – with no operator intervention of additional automation required.

Featuring automatic load/unload and part picking functions designed with today’s high speed punching & bending capabilities in mind.and enabling automated production from stored raw material to stacked finished part.The AP-50 can run in a complete “lights out” manufacturing environment.

Quick Details

Condition: New

CNC or Not: CNC

Power Source: Mechanical

Place of Origin: Anhui, China (Mainland)

Brand Name: AccurL

Model Number: TC-MAX1250

Voltage: 380V/220V Optional

Power(W): 10.5Kw

Weight: 7850Kg

Dimension(L*W*H): 5190*3250*2550mm

Certification: CE ISO

Warranty: 2 years warranty time

After-sales Service Provided: Engineers available to service machinery overseas

Punch Force: 30 tons

Max. Processing Size: 5000*1250mm (With second position)

Max. sheet Thickness: 4mm

Max. Traversing Speed: 80m/min

Servo System: Siemens servo drive

CNC System: Siemens Sinumerik 840D Windows XP

linear guide and ball screw System: Germany Rexroth

Main motor: Siemens Electrical

Electrical components: Siemens Electrical

Programming software: CNCKAD from Israel

KEY FEATURES

•Automated production from stored raw material to stacked finished part

•Fast loading system

•Automatic sheet thickness control and automatic sheet separator devices ensure efficient material loading

•Intuitive touch screen graphical user interface

PRODUCTIVITY-ENHANCING OPTIONS

•Second loading pallet

•Part picking and sorting for scratch-free unloading

•Full integration with an existing warehouse

MODELS

•Available for SF/EM-20 Series punch presses

•Available for Smart Fab Series CNC press brake

SPECIFICATIONS

•Maximum sheet size: up to 60″ x 120″ (3050 x 1525 mm)

•Part sizes from 7.8″ x 3.9″ (200 x 100 mm)

•Maximum load table capacity: 6000 lbs (3000 kg)

•Maximum material thickness: 0.5″ (4 mm)

Standard Execution:

– ‘O’ Frame design tested by Finite Element Analysis software, precisely machined and stress relieved to ensure high precision

– Hydraulic punching with indexable tool station through 360° in increments of 0.001°

– Punching, cutting and forming processes subject to optional tooling fitted -controlled by the CNC according to material

– Capable of producing not only 2D components but when fitted with special tools can create 3D forms which wouldn’t be possible when using a profiling process

– High nibbling rate of 600 hits per minute in 1mm pitch

– High capacity motors and precision guides on all axes able to reach high operational speeds

– Rigid beam with fitted with two sheet clamps capable of positioning sheets of up to 8mm thickness

– Very accurate repeatability of 0.04mm

– Clamping force adjusted by CNC from 100kg to 1000kg

– Repositioning feature

– High processing speeds and data transfer rates

5-axis CNC Robot Bending and CNC Turret Punch Press with the AP-50 load/unload automation system with part picking and stacking eliminates all manual sheet handling.

One of the most flexible automation systems available for punching & bending. The AP-50 system can handle small and large volume applications with common material type, thickness and size and small as well as large work pieces. AP-50 offers advanced load/unload, part picking and a large area for stacking punched parts directly onto the allocated pallet – with no operator intervention of additional automation required.

Featuring automatic load/unload and part picking functions designed with today’s high speed punching & bending capabilities in mind.and enabling automated production from stored raw material to stacked finished part.The AP-50 can run in a complete “lights out” manufacturing environment.

Quick Details

Condition: New

CNC or Not: CNC

Power Source: Mechanical

Place of Origin: Anhui, China (Mainland)

Brand Name: Primapress

Model Number: TC-MAX1250

Voltage: 380V/220V Optional

Power(W): 10.5Kw

Weight: 7850Kg

Dimension(L*W*H): 5190*3250*2550mm

Certification: CE ISO

Warranty: 2 years warranty time

After-sales Service Provided: Engineers available to service machinery overseas

Punch Force: 30 tons

Max. Processing Size: 5000*1250mm (With second position)

Max. sheet Thickness: 4mm

Max. Traversing Speed: 80m/min

Servo System: Siemens servo drive

CNC System: Siemens Sinumerik 840D Windows XP

linear guide and ball screw System: Germany Rexroth

Main motor: Siemens Electrical

Electrical components: Siemens Electrical

Programming software: CNCKAD from Israel

KEY FEATURES

•Automated production from stored raw material to stacked finished part

•Fast loading system

•Automatic sheet thickness control and automatic sheet separator devices ensure efficient material loading

•Intuitive touch screen graphical user interface

PRODUCTIVITY-ENHANCING OPTIONS

•Second loading pallet

•Part picking and sorting for scratch-free unloading

•Full integration with an existing warehouse

MODELS

•Available for SF/EM-20 Series punch presses

•Available for Smart Fab Series CNC press brake

SPECIFICATIONS

•Maximum sheet size: up to 60″ x 120″ (3050 x 1525 mm)

•Part sizes from 7.8″ x 3.9″ (200 x 100 mm)

•Maximum load table capacity: 6000 lbs (3000 kg)

•Maximum material thickness: 0.5″ (4 mm)

Standard Execution:

– ‘O’ Frame design tested by Finite Element Analysis software, precisely machined and stress relieved to ensure high precision

– Hydraulic punching with indexable tool station through 360° in increments of 0.001°

– Punching, cutting and forming processes subject to optional tooling fitted -controlled by the CNC according to material

– Capable of producing not only 2D components but when fitted with special tools can create 3D forms which wouldn’t be possible when using a profiling process

– High nibbling rate of 600 hits per minute in 1mm pitch

– High capacity motors and precision guides on all axes able to reach high operational speeds

– Rigid beam with fitted with two sheet clamps capable of positioning sheets of up to 8mm thickness

– Very accurate repeatability of 0.04mm

– Clamping force adjusted by CNC from 100kg to 1000kg

– Repositioning feature

– High processing speeds and data transfer rates

#press brake robots #horizontal press brake #dies press brake

#metal brake press #press brake damant #servo press brake

#brake caliper press