Description

Primapress Full Electric Servo Bending Machine press brake pure electrical press brake bending machine :

The Primapress ECO series is an all-electric transmission mode, and the servo motor drives the screw. It has the highest precision and the fastest processing efficiency among various series of bending machines. The patented software has good compatibility. The use is still accurate, different from the traditional bending machine that does not need oil, and the motor only runs when it is working, energy-saving, environmentally friendly and clean, and has better adaptability for customers who have higher requirements for the plant environment.

- Output according to the actual tonnage, saving energy and electricity.

- Pure electric does not need oil, environmental protection and cost saving, low noise, suitable for enterprises with high requirements in processing environment.

- The efficiency is increased by 100%, the speed is fast, and the output is increased.

- High precision, the repeatability of the fully closed-loop control slider is 0.01mm, and the repeatability of the rear gear is 0.05mm.

- The actual tonnage output makes the machine more durable and does not damage the knife mold.

- The software and hardware of the servo motor have good compatibility, the system is stable, and the machine does not stop all day.

- All-steel welded structure, manganese steel material has a good rebound coefficient, and the stress is relieved by vibration demagnetization, tempering and sanding treatment, and the body is stable and durable.

- Direct manufacturer, one-stop service, to solve customer’s knife mold design, product, automation and other problems, the whole machine is guaranteed for three years.

Full Electric Servo Bending Machine press brake pure electrical press brake bending machine Specification:

| No | Name | Item | P30T | P20T | |

| 1 | Force | T | 30 | 20 | |

| 2 | Worktable | mm | 1250 | 600 | |

| 3 | Column gap | mm | 1070 | 570 | |

| 4 | Throat | mm | 300 | 200 | |

| 5 | Stroke | mm | 150 | 120 | |

| 6 | Open height | mm | 430 | 420 | |

| 7 | Backgauge(optional) | mm | 500 | 250 | |

|

8 |

Stroke | Down | mm/s | 200 | 200 |

| Working | mm/s | 1-30 | 1-30 | ||

| Return | mm/s | 200 | 200 | ||

|

9 |

Servo | Power | KW | 7.5 | 7.5 |

| Nos | Set | 1 | 1 | ||

| 10 | Control | Model | ECO-10ES | ECO-10ES | |

| Axis | 2 | 2 | |||

| 11 | Size | L | mm | 750 | 750 |

| W | mm | 1000 | 1000 | ||

| H | mm | 2100 | 2100 | ||

| 12 | Weight | Kg | 2500 | 1500 | |

Full Electric Servo Bending Machine press brake pure electrical press brake bending machine Main configuration list

| No | Name | Supplier | Remark |

| 1 | Servo motor | Easycat | |

| 2 | Linear guides | Easycat | |

| 3 | Ball screw | Hiwin Taiwan | |

| 4 | Electrics | Schneider | |

| 5 | Bearing shaft | Luoyang | |

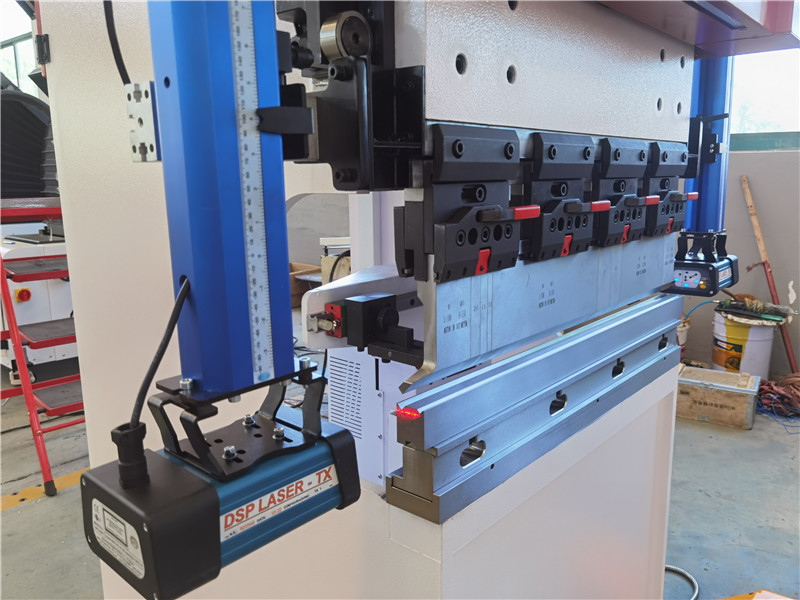

| 6 | CNC system | ET 15 2D Touch screen | |

| 7 | Machine body | Primapress |

Full Electric Servo Bending Machine press brake pure electrical press brake bending machine More Features and functions :

- Finite element analysis for high rigidity design

The key mechanical parts of the machine tool use finite element analysis to analyze the deformation and safety factor to ensure the high rigidity requirements of the machine tool as a whole and the reliability of long-term use.

2.ET 15 CNC system

ET 15 CNC system is mainly used in the field of all-electric servo bending machines. It is a high-end CNC system tailored according to market demand. It has powerful functions, rich built-in resources, and features products that are safe, efficient, energy-saving and environmentally friendly. .

CNC system product features

Reliable performance

The CNC system ET 15 adopts a high-end CNC system development platform and advanced sheet metal bending special algorithms and motion control algorithms. The main board adopts industrial-grade chips. The CNC system has passed EMC electromagnetic compatibility verification and high and low temperature environmental adaptability testing.

High-speed and high-precision control

The CNC system adopts high-speed acceleration and deceleration algorithm and trajectory look-ahead algorithm. Before bending, the CNC system makes an overall planning of the motion trajectory according to the bending speed and vector characteristics, and ensures good bending accuracy while accelerating and decelerating at high speed. And soft motion characteristics, so that high speed and high precision are effectively integrated!

High speed: The maximum fast forward speed of the Y axis is 200mm/s, and the working speed is 0-30mm/s.

High precision: repeat positioning accuracy ±0.01mm.

Processing consistency: The influence of oil temperature changes on the consistency of bending workpieces is avoided.

- Energy saving and environmental protection

The CNC system ET 15 is mainly used in all-electric servo CNC bending machines, especially power saving and green environmental protection.

Special power saving: the difference in electricity consumption between the all-electric servo bending machine and the electro-hydraulic servo bending machine is like the difference between the inverter air conditioner and the ordinary air conditioner.

Green and environmental protection: no need to use and replace hydraulic oil, which ends the pollution of waste hydraulic oil to the environment.

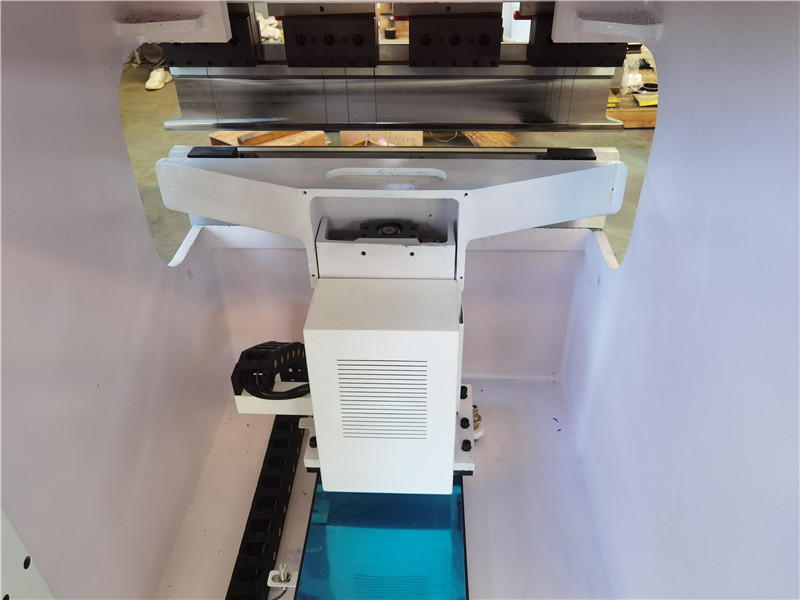

4 spindle power box

The spindle power box can transmit the bending pressure, adopts heavy-duty ball screws and bearings, ultra-long life design, and seal protection design ensures that key components are not affected by external dust.

Spindle power box/synchronizing wheel/AC servo motor

Main technical indicators and functions: