Description

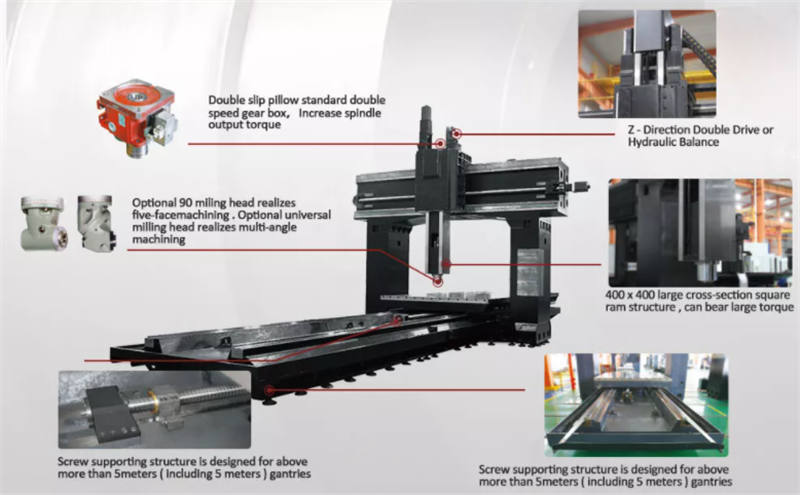

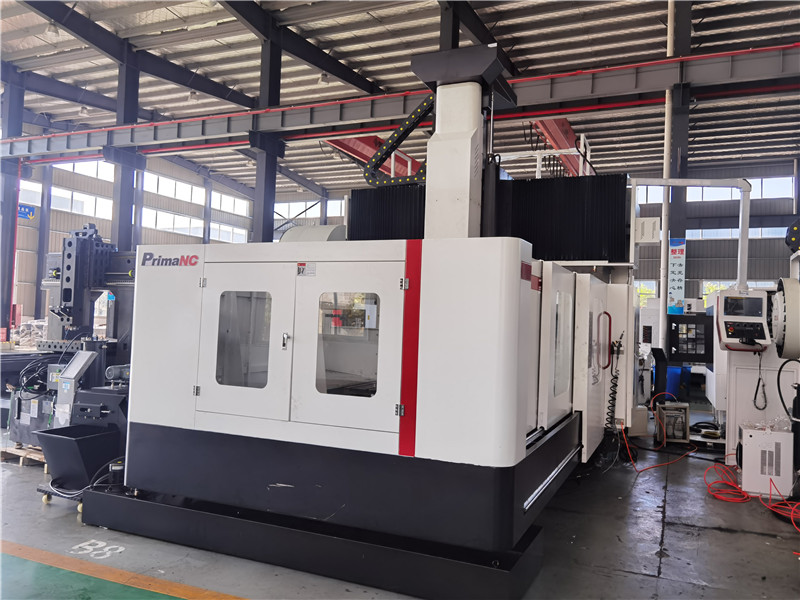

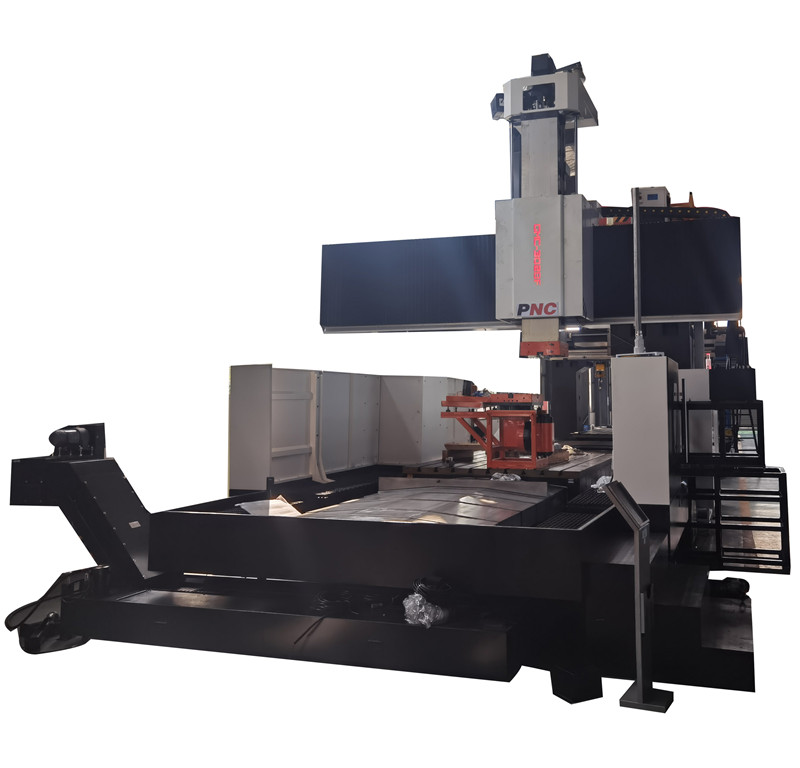

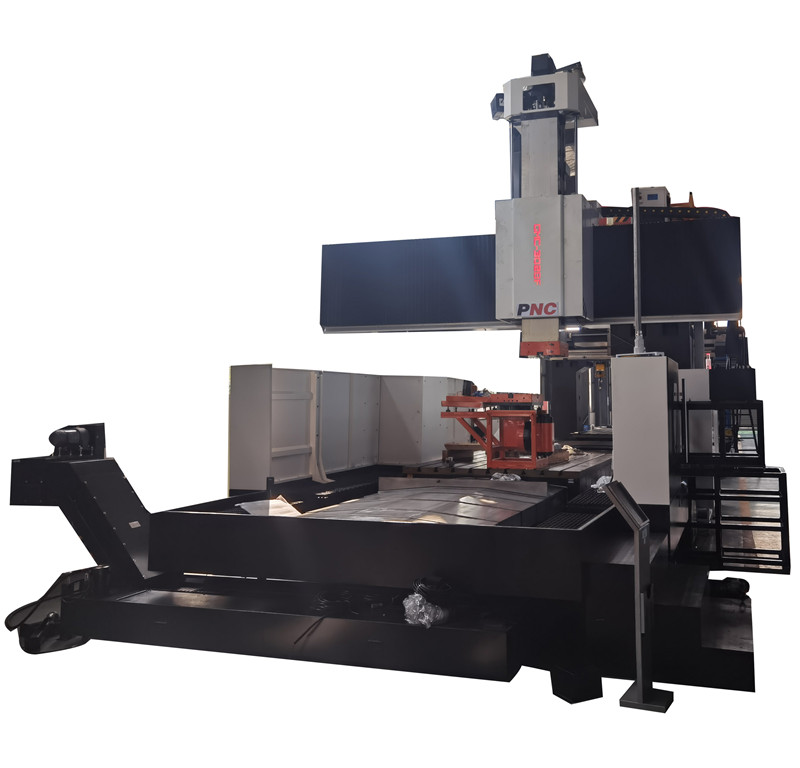

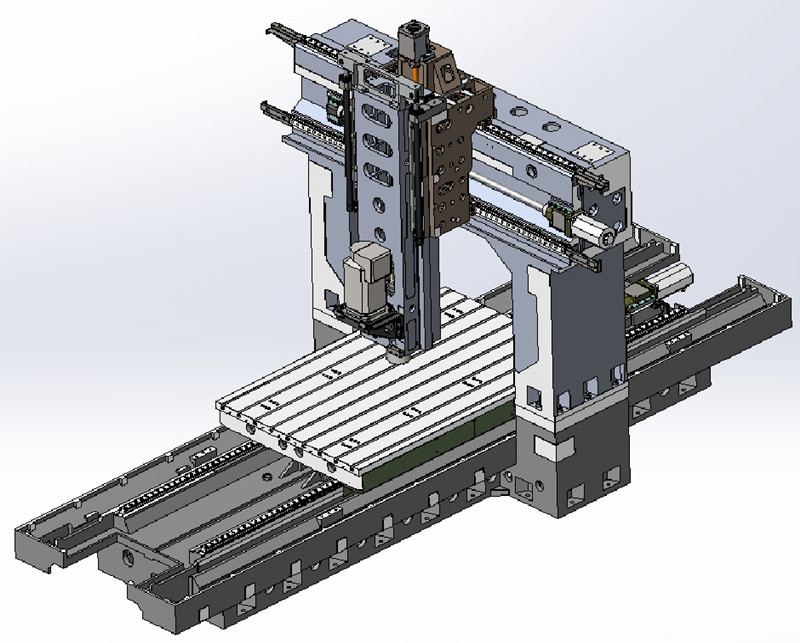

FANUC controller gantry CNC milling machine GMC 1611 heavy cutting double column gantry type CNC machining center

This machine is suitable for processing machinery and mold manufacturing field of vertical machining center, from the rough machining and finish machining and processing requirements apply, can finish milling, drilling, tapping, boring, and a variety of processes.

Main Parameter: we can make all kinds models based on your requirement.

| Machine Type | Unit | GMF4027B |

| Workbench size | mm | 4000/2300 |

| Door width | mm | 2500 |

| Workbench load bearing | T | 12 |

| T-slot width | mm | 9-22X200/2-22X140 |

| X/Y/Zaxis travel | mm | 3200/2500/1000 |

| Spindle end to table distance | mm | 255-1255 |

| Taper hole type | BT50 | |

| Pull stud specifications | P50T-1-MAS403 (45°) | |

| Speed range | rpm | 10-5000 |

| Main drive form | Spindle motor + ZF gearbox + belt | |

| Cutting feed rate range | m/min | 7 |

| X-axis rapid movement | m/min | 10/12/10 |

| System configuration FANUC Oi MF 1 package | ||

| X/Y/Z axis motor | αiF40/αiF30/2-αiF40B | |

| Spindle motor αiI22 | ||

|

Triaxial guide rail specifications |

X-axis 2-55# roller rail | |

| Y-axis 2-55# roller track | ||

| Z-axis square ram | ||

|

Triaxial screw specifications |

X-axis 8016 | |

| Y axis 6316 | ||

| Z axis 5010 | ||

|

Bearing specifications |

X-axis 60TAC120B | |

| Y axis 50TAC100B | ||

| Z axis 40TAC90B | ||

| Mainframe dimensions about | mm | 7890X4850X5130(highest point of travel) |

| Host weight approx. | T | 18 |

(1) 36 months quality guaranty

(2) free lifetime maintenance

(3) free training course in our factory.

(4) 18 hours on line service each day

(5) Strict quality control,3 times of testing

(6) engineers avaiable to go abroad

Main accessories

| Serial No | name | number | Manufacturer | Specification and model |

| 1 | system | 1set | Fanuc, Japan | FANUC 0i-MF;10.4″Color LCD display |

| 2 | Spindle servo motor | 1set | Fanuc, Japan | βiIP30/8000 |

| 3 | X、Y、Z servo motor | 1 set for each | Fanuc, Japan | βiS 40/2000 /βiS 40/2000 /βiS 40/2000B |

| 4 | X、Y、Z Shaft lead screw bearing | 1 group for each | Germany FAG / Japan NSK | 50 x 100/40×90 |

| 5 | X-axis ball screw | 1 group for each | Japan THK / Taiwan HIWIN / PMI | GQ63×12-C3 |

| 6 | Y-axis ball screw | 1 group for each | Japan THK / Taiwan HIWIN / PMI | GQ50×10-C3 |

| 7 | Z-axis ball screw | 1 group for each | Japan THK / Taiwan HIWIN / PMI | GQ50×10-C3 |

| 8 | X-axis linear guide rail | 2strip | Germany INA/ Taiwan

HIWIN/PMI |

55(8slider) |

| 9 | Y-axis linear guide rail | 2strip | Germany INA/ Taiwan

HIWIN/PMI |

55 |

| 10 | Z-axis linear guide rail | 2strip | self-control | quench |

| 11 | Tool magazine | 1 set | Okada | 24 disc type |

| 12 | Automatic lubrication system | 1 set | Proton | 4L |

| 13 | Main pneumatic components | 1 set | gold plate | |

| 14 | Main electric components | 1 set | Schneider | |

| 15 | Main drive toothed belt | 1group | JapanUNITTA | |

| 16 | air conditioner | 1set | Commissure width |

If any supplier fails to supply, it will be replaced by a brand of no less than the same quality.