Description

CNC servo hydraulic turret punch machine cnc turret punching machine with index molds

Servo CNC Servo Turret Punch press

Brief Introduction

Specifications

- Nominal force KN 300

- Workpiece size mm 1500*5000

Max workpiece weight Kg 156

- Max workpiece thickness mm 6.35

5.Max punch diameter mm Ф88.9

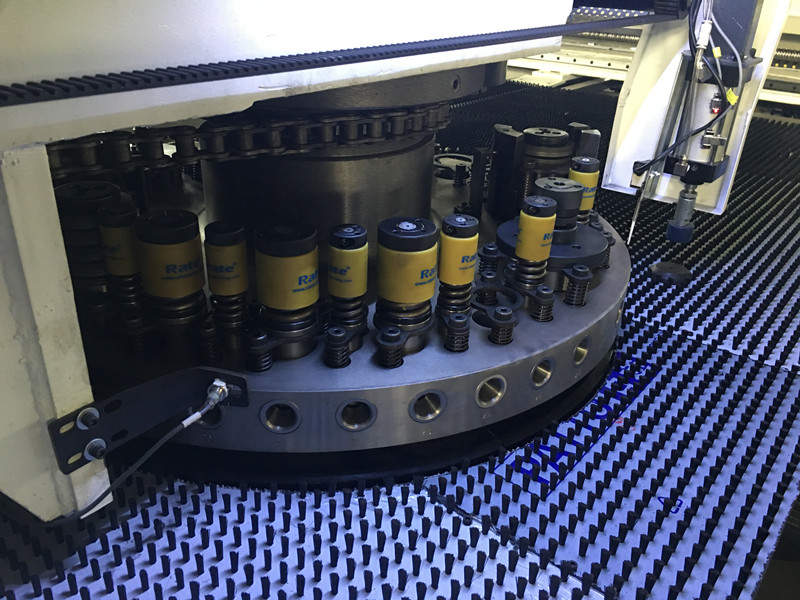

6.Number of stations 32

Working accuracy mm ±0.1

Max. hit speed HPM 600

Workpiece traveling speed m/min 106

Turret speed r/min 30

Frame construction Closed-type

Throat mm 1275

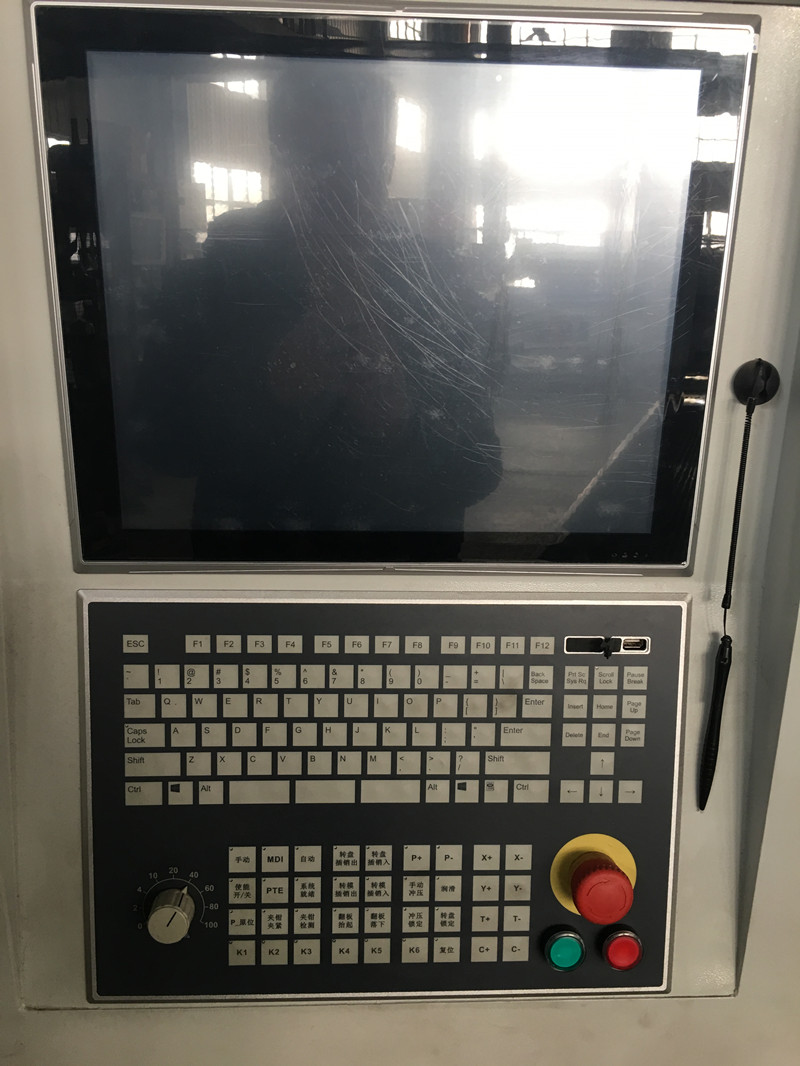

Number of control axis 5 axes (X, Y, T, C)

Max rotary station punching diameter mm Ф50.8

Repeatability mm 0.02

Number of clamp 2

Clamp type Pneumatic type

Heat treatment of the frame Tempering

Tool type Long guide sleeve type

(AMADA)

Turret construction Long bushing in the thin turret

Air pressure Mpa 0.6

Machine dimension (L*W*H) mm 5300*5000*2200

Machine weight kg 18500

- Machine Feature

- Advanced and reliable Servodrive system can select stroke automatically corresponding to different thickness of metal sheet and is convenient to realize special process of louver, blanking, etc. The punch is equipped with auto Servooverload protection device, and guarantees consistent pressing force for quality products.

- The punch is of Germany Siemens0iP control system.

- Rotary tooling stations are of worm wheel structure with max. punching diameter of Ф50.8.

- Dual turret is of long insert structure ensuring coaxiality of the punch and die, which gives long life to the tool and turret.

- Imported pneumatic and Servocomponents guarantee reliability of the machine.

Imported ballscrews with long travel, and linear guideways ensure transmission precision.

The worktable with hard brush and steel ball reduces noise and shock of the machine, and protects surface of the work piece.

The machine is straight-side frame, which is annealed for eliminating inner stress.

The clamps with auto protection function, in the protective zone, only excise movement without punching action for continuous operation.

10.Central lubrication device provides lubricant oil to the desired points to reduce friction of pairing elements for long machine life.

12.Tool station layout consists of A、B、C、D, which is convenient for the customer and save the tool cost.

13.Common requirement is for site foundation preparation and machine installation is simple.