Description

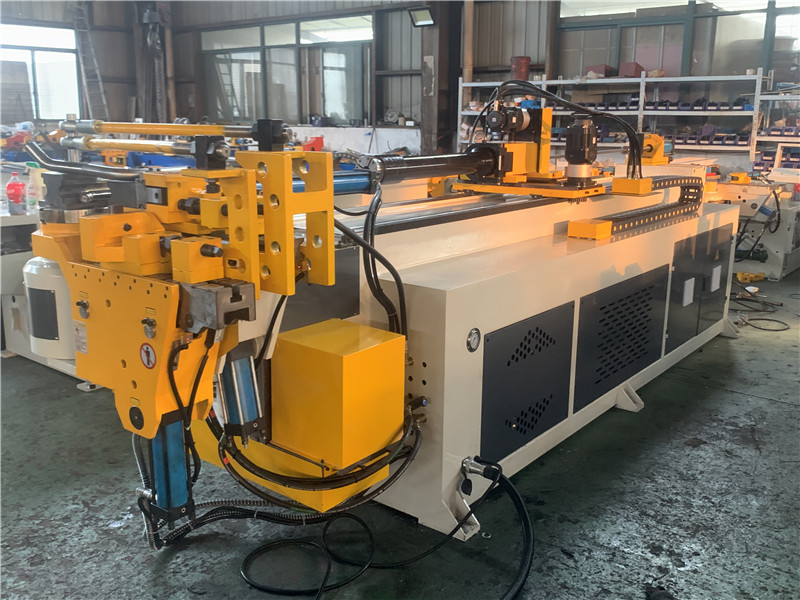

Automatic Pipe Bending Machine 130 CNC Automatic Cold Pipe Bending Machine Hydraulic for Big Heavy Steel Tube

Technical Parameter and Configuration for Automatic Pipe Bending Machine DW114CNC-2A1S

- Machine Characteristic

The series was adapted in particular to professional world market requirements. All the parts, structure and characters are similar to the standard of mechanical engineering from Europe.Our professional experience and drawings plans for Electric, Electronic, Hydraulic and mechanical from known companies bring to upgrading of the machines’ systems to accurate and attractive performance.

GM-SB-CNC Series numerical control single-head pipe bending machine is the product from the combination with our technology and advanced Italian technology, integrated with machine, hydraulic, and electricity. This series adopt VDU touch screen operating panel, which can input, store, and display various bending data and order. Y, B, C three coordinates of motion under precision control by industrial computer can realize full-auto mandrel on or mandrel off rapid bending, CNC machine also with advanced functions, such as components bending spring back compensation, errors self diagnose alarm, memory store after power off, automatic lubrication and safety protection. Advanced technology, high automation reliability, integrated design all make CNC pipe bending machine the first class pipe processing machine in the world.

Main Technical Parameter

parameter

| Model | DW18CNC-2A1S | DW25CNC-2A1S | DW38CNC-2A1S | DW50CNC-2A1S | DW63CNC-2A1S | DW75CNC-2A1S | DW89CNC-2A1S | DW114CNC-2A1S |

| Maximum pipe diameter × wall thickness | Φ19×1.5 | Φ25×1.8 | Φ38×2.0 | Φ51×2.0 | Φ63×2.5 | Φ76×3.0 | Φ89×3.0 | Φ114×8.0 |

| Standard feeding distance | 1200mm | 1800mm | 2200mm | 2500mm | 2500mm | 2600mm | 3200mm | 3600mm |

| Feed type | Straight feeding or jig | Straight feeding or jig | Straight feeding or jig | Straight feeding or jig | Straight feeding or jig | Straight feeding or jig | Straight feeding or jig | Straight feeding or jig |

| Maximum bending radius | 90mm | 120mm | 175mm | 200mm | 250mm | 300mm | 350mm | 400mm |

| Maximum angel of bending | 185° | 185° | 185° | 185° | 185° | 185° | 185° | 185° |

| Numbers of single pipe bends | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 |

| Numbers of parts saved | 400sets | 400sets | 400sets | 400sets | 400sets | 400sets | 400sets | 400sets |

| Rotation pace | Max.270°/s | Max.270°/s | Max.270°/s | Max.270°/s | Max.270°/s | Max.180°/s | Max.180°/s | Max.180°/s |

| Feeding pace | Max.1000mm/s | Max.1000mm/s | Max.900mm/s | Max.900mm/s | Max.900mm/s | Max.700mm/s | Max.700mm/s | Max.700mm/s |

| Rotation accuracy | ±0.15° | ±0.15° | ±0.15° | ±0.15° | ±0.15° | ±0.15° | ±0.15° | ±0.15° |

| Feeding accuracy | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| Rotation servo power | 400W | 400W | 400W | 750W | 750W | 1KW | 1KW | 1.5W |

| Feeding servo power | 750W | 1KW | 1KW | 1KW | 1.5W | 2KW | 2KW | 3.5W |

| Oil pressure motor power | 3KW | 3KW | 4KW | 5.5KW | 5.5KW | 7.5KW | 11KW | 15KW |

| Total weight | 1200KG | 1350KG | 2000KG | 2500KG | 2800KG | 3600KG | 4000KG | 5000KG |

| boundary dimension(mm) | 2760×690×1000 | 3000×780×1100 | 3400×780×1160 | 4200×850×1160 | 4300×850×1160 | 5700×1080×1400 |

you can make a choice and contact with Primapress

- Configuration of Hydraulic and Electronic Control System

| Name | Manufacturer |

| Hydraulic Motor | Germany Siemens(Beide) |

| Hydraulic Pump | Wuxi Tuoli |

| Hydraulic Valve | Japan Yuken(Imported) |

| Oil way Board | Taiwan Shanghong (Imported) |

| Cylinder | Shanghai Qifan |

| Touch screen | Taiwan Weinview(Imported) |

| PLC | Japan Mitsubishi(Imported) |

| Angle controller | Japan Nemicon(Imported) |

| Switch power | Taiwan Mingwei |

| Rotating/feeding servo motor | Japan Mitsubishi(Imported) |

| Transformer | Wuxi Xinyu |