Description

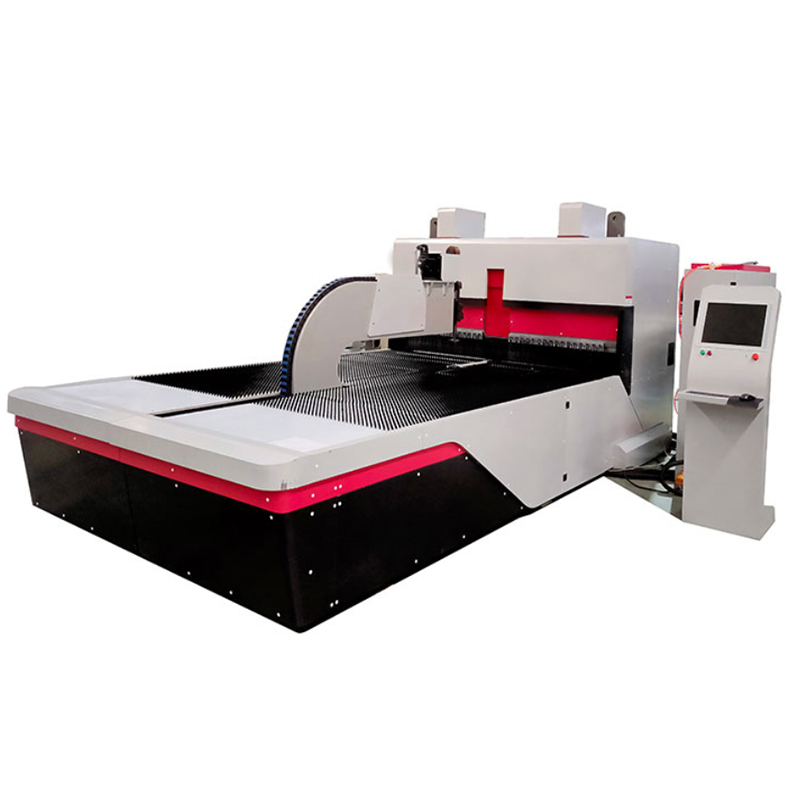

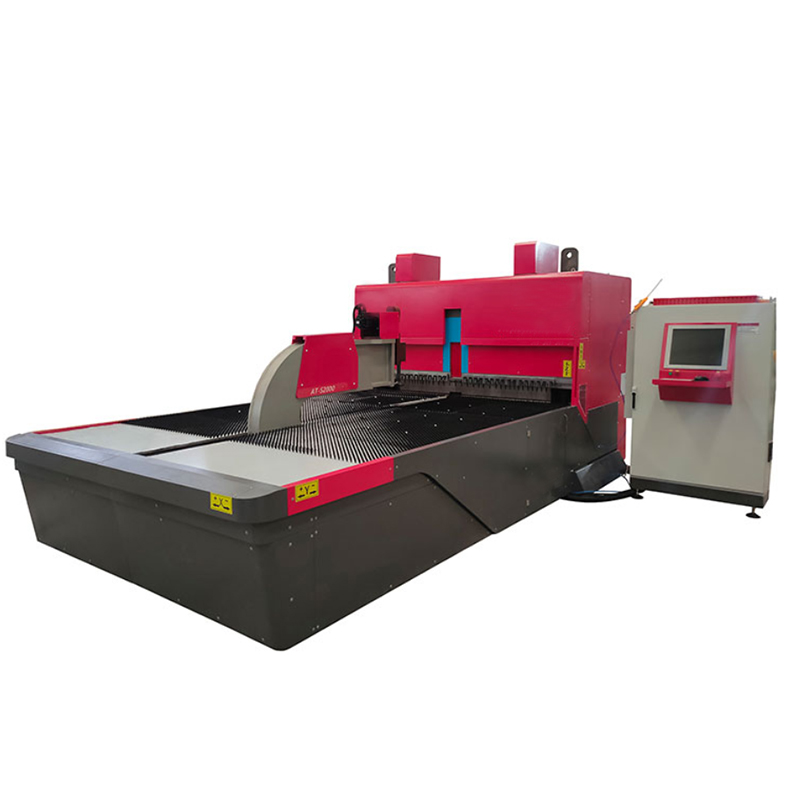

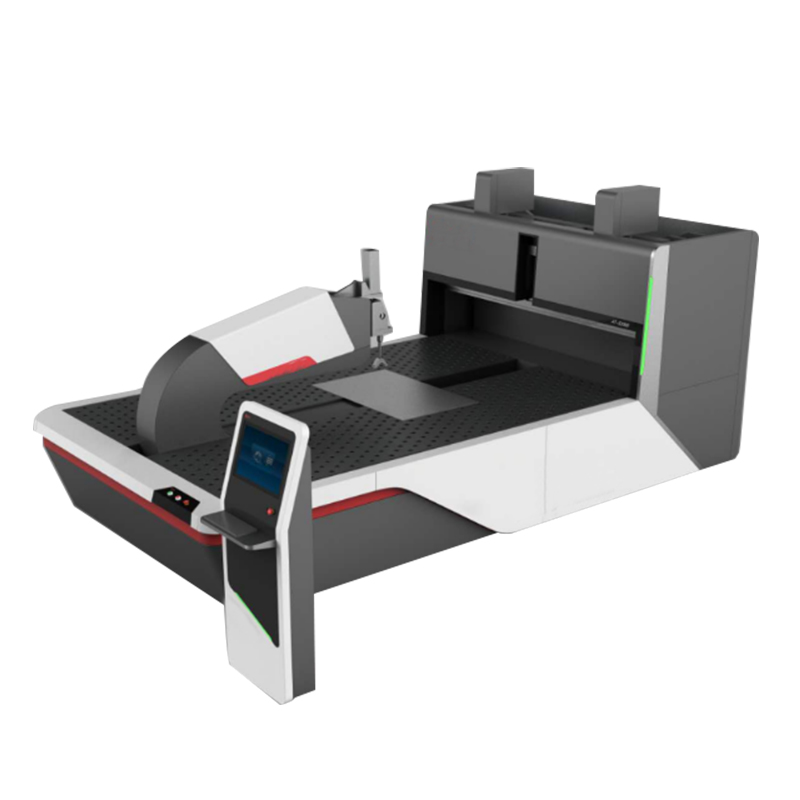

15 Axis Sheet Metal Bending Center Panel Bending Machine CNC 2000mm panel bender machine

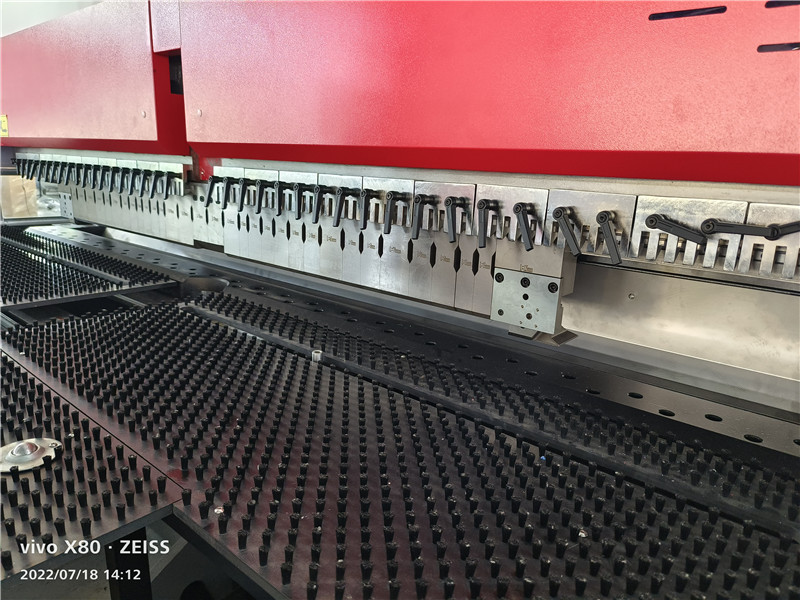

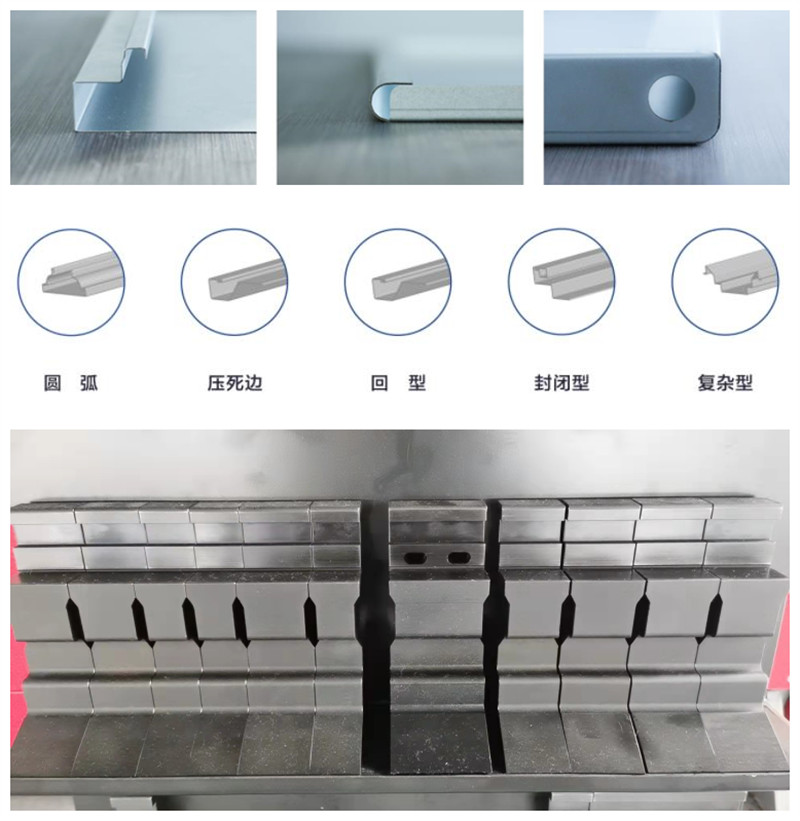

Primapress panel bender bending center adopts a full servo system. Unlike traditional bending machines, the bending machine mold needs to be pressed down against the fixed part of the bending machine, but the bending work is completed by the blade. During the bending process, the plate The material holder fixes the plate. The blade can be bent up or down in different shapes. First, one side is bent outward, and then it is automatically bent inward. These different actions are controlled by the servo electric drive device, which can ensure the highest positioning accuracy in the bending sequence and bring the best bending effect.

Industry Application*Food machinery, goods and household appliances

*Steel furniture, sheet metal and warehouse *Electrical cabinet

*Steel door and frame *Elevators and escalators

*Generators *Hospital and laboratory equipment

*HVAC *lighting device

15 Axis Sheet Metal Bending Center Panel Bending Machine CNC 2000mm panel bender machine Product Paramenters

| Name | Brands |

| Operating system | Above Windows 7 |

| Control system | 9 axis + concurrent linkage control system |

| Servo motor | Independent R&D, full closed-loop control |

| Screw | Taiwan-HIWIN |

| Bearing | NSK |

| Linear guide | Taiwan-HIWIN |

| Machine bed | High grade casting integral forming |

| Bending knife | Patented ball cutter head, more wear-resistant, longer service life |

| Sucker | AIRBEST |

| Pneumatic component | Japan SMC |

| Oil system | Taiwan |

Specifications:

15 Axis Sheet Metal Bending Center Panel Bending Machine CNC 2000mm panel bender machine PRODUCT SPECIFICATIONS

| 0 | Model | AT2000 |

| 1 | Maximum bending speed | 0.2 s/time |

| 2 | Maximum bending width | 2000mm |

| 3 | Maximum bending size | 2000*1250mm |

| 4 | Bending height | 170mm |

| 5 | The rated voltage | 380V |

| 6 | Peak power | 25KW |

| 7 | CNC system | PC-Base New Independent Research and Development 9 Axis Linkage Full Servo CNC System |

| 8 | Lathe bed | Casting bed |