Procurement knowledge of electro-hydraulic servo cnc press brake bending machine

The electro-hydraulic servo cnc press brake bending machine is a kind of bending machine, which uses the servo motor as the actuator, and uses the CNC system and the grating ruler feedback data to control the flow ratio of the main cylinders on both sides to achieve the synchronous movement of the slider. In addition, the bending machine constitutes a closed-loop control, with accurate feedback and accurate slider operation, so that the bending accuracy and slider repeated positioning accuracy are high. Do you know the performance characteristics of the bending machine? If you are not clear, let’s take a look at the following introduction.

The performance characteristics of the electro-hydraulic servo cnc press brake bending machine are described in detail as follows:

- The electro-hydraulic servo cnc press brake bending machineadopts the hydraulic bulge automatic compensation system to solve the influence of the deformation of the slider during the bending process on the workpiece quality. The compensation quantity is automatically adjusted by the numerical control system, which is convenient and accurate.

- The electro-hydraulic servo cnc press brake bending machineadopts a fully functional rear stopper mechanism, which can control multiple rear stopper shafts. Functional parts in the rear stopper. For example, the guide rail, lead screw, bearing, etc. are all imported components to ensure the accuracy of the rear stopper.

- The body of the electro-hydraulic servo cnc press brake bending machineadopts an integral welding structure, which is convenient for transportation and processing, and can ensure the overall accuracy of the machine tool.

- The body, slider and other important parts of the electro-hydraulic servo cnc press brake bending machineare analyzed by ANSYS finite element analysis software to ensure the reliability of the machine tool.

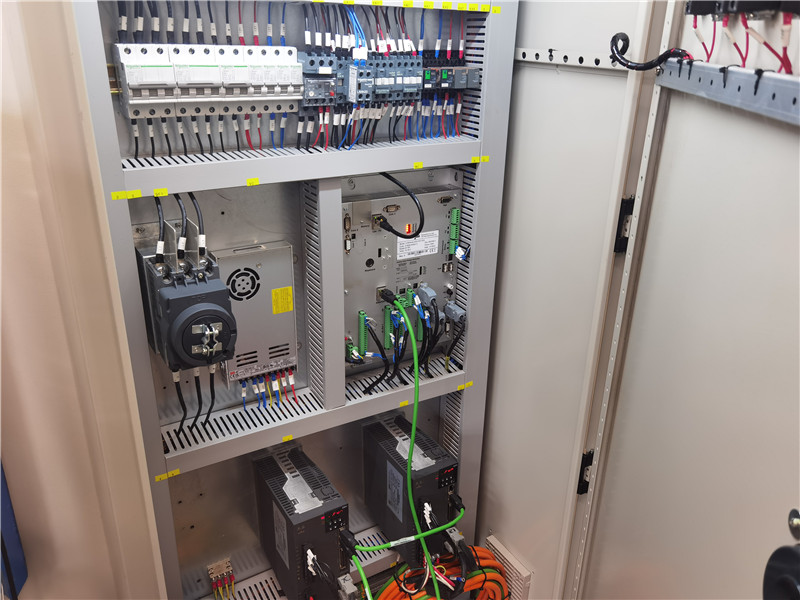

- The hydraulic system of the electro-hydraulic servo cnc press brake bending machinereduces pipeline installation, improves the working stability of the machine tool, and has a beautiful and simple appearance.

What should be paid attention to when purchasing electrohydraulic bending machine?

Performance characteristics of electro-hydraulic bending machine

- The main machine is equipped with a special numerical control system for the plate shearing machine.

- The rear stopper position is displayed in real time.

- Multi step programming function, automatic operation and continuous positioning of the rear stopper, realizing automatic adjustment of the rear stopper position.

- The cutting counting function can display the cutting quantity in real time, and memorize the position, program and parameters of the rear stopper after power failure.

- Imported ball screw and linear guide rail are used to ensure the positioning accuracy and higher machining accuracy.

How to choose and purchase electrohydraulic bending machine?

- The main difference between the electro-hydraulic servo cnc press brake bending machineand the ordinary cnc press brake bending machinelies in whether there is a feedback loop and whether there is electro-hydraulic bending machine compensation.

- Calculate the number of tons of plate shears to be purchased according to the material and thickness of metal plates to be processed and bent; Note: The tonnage here refers to the maximum pressure of the bending machine, not the weight of the electro-hydraulic servo cnc press brake bending machine;

- Determine the knife edge width, throat depth and distance between columns of the electro-hydraulic servo bending machine according to the length of stainless steel and other plates to be processed. After determining the tonnage and main parameters, you can start to find the appropriate manufacturer;

- Manufacturer or brand of electro-hydraulic synchronous bending machine. The electro-hydraulic bending machine is more intelligent and fully automatic. The quality, price and after-sales service of different manufacturers are quite different; Domestic brands are the top ten brands such as Yawei;

- There are many optional additional functions of the electro-hydraulic servo synchronous bending machine, which need to be customized according to the requirements of the processing workpiece, such as the number of shafts, compensation type, laser testing, safety protection (laser protection or light curtain protection), etc.