Operation steps and precautions for the use of metal 2D and 3D wire forming bending machine

Using a metal wire forming bending machine to process and produce metal wire forming bending products, there is a professional process, to complete a complete set of

wire forming bending production process, let’s take a look at the precautions for the use of the metal wire forming bending machine.

1. When the metal wire molding product is abnormal, it must be stopped before adjustment and modification.

2. When the machine is running, it is prohibited to touch the panel of the CNC steel wire bending machine by hand.

3. The direction of the drop of metal wire molding products must be controlled. (I believe every master is familiar with it) so as not to jam the knife holder and cause collision.

4. Start the machine in strict accordance with the steps of use. Before production, all fasteners transferred during adjustment must be checked to avoid loosening,

falling, shifting, collision phenomenon, and damage to the machine.

5. When the CNC steel wire bending machine is damaged, it must be inspected and corrected by experienced personnel. When reporting for repairs, the relevant professionals

should perform the repairs. It is strictly forbidden to disassemble without professional and technical personnel to avoid secondary damage.

Scope of application: suitable for various small buckle products such as iron wire, steel wire, copper wire, stainless steel wire, aluminum wire, etc. (Circle, semicircle, ellipse,

square, flat, sheet) bending and processing into regular and irregular shapes such as square buckle, round circle, oval buckle, S hook, 9-shaped needle, 8-shaped buckle, plum

blossom buckle, etc. Various products.

Operation steps of automatic metal wire bending machine

2D and 3D Automatic metal wire bending machine is a kind of mechanical equipment, we must pay attention to it when operating it, and don’t make mistakes. In order to prevent

operation errors, we will look at the operation steps of the automatic metal wire bending machine today.

Before the operation of the automatic 2D and 3D metal wire bending machine:

1. The automatic metal wire bending machine must be well grounded, and it is not allowed to connect to the power supply voltage exceeding the specified range, and the

plug-ins cannot be plugged or unplugged when the power is on, otherwise the accessories may be damaged;

2. Proximity switches, encoders, etc. cannot be hit by hard objects;

3. Do not hit the display unit with sharp objects;

4. The automatic metal wire bending machine equipment must be placed in a dry and ventilated place to prevent corrosion and rust;

5. Do not install or change the PC input and output terminals without permission;

6. The automatic metal wire bending machine should be kept clean, and special attention should be paid to no foreign matter in the wire feeding and corner folding area;

7. Add lubricating oil regularly;

- Die adjustment: the molds such as wire feeder, conduit, short wire guide, closed cutter, open cutter, cylindrical angle head, fixed angle head, angle plate,

- small straight angle knife and other tools are correctly installed .

Automatic metal wire bending machine in operation:

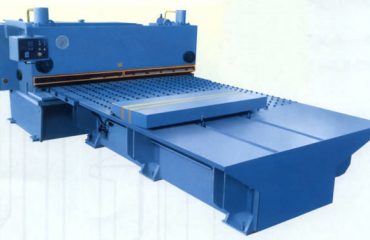

Primapress Metal 2D and 3D Wire forming bending Machine

1. When the machine starts to operate, the operator must stand in a safe area;

2. When the product is cut off, the direction should be controlled to avoid hurting people;

3. After using the machine for a period of time, check the relevant configuration.

CNC 2D and 3D steel wire bending machine