Operating procedures and precautions for use of plate shears metal shearing machine

Operating Instructions

First: Carefully implement the relevant provisions of the General Operating Procedures for Forging Equipment.

Second: Seriously implement the following supplementary provisions:

- Before work:

1) Before idling test run, manually turn the machine for one working stroke, and start the equipment after confirming that it is normal.

2) For equipment with hydraulic device, the oil volume in the oil storage tank shall be sufficient. After starting the oil pump, check whether there is any leakage in the valve and pipeline, and the pressure should meet the requirements. Open the bleeder valve to drain the air in the system.

- Earnestly accomplish:

1) It is not allowed to cut the laminated sheet, trim the edge of the rough edge sheet, and cut the narrow sheet and short sheet that cannot be pressed tightly.

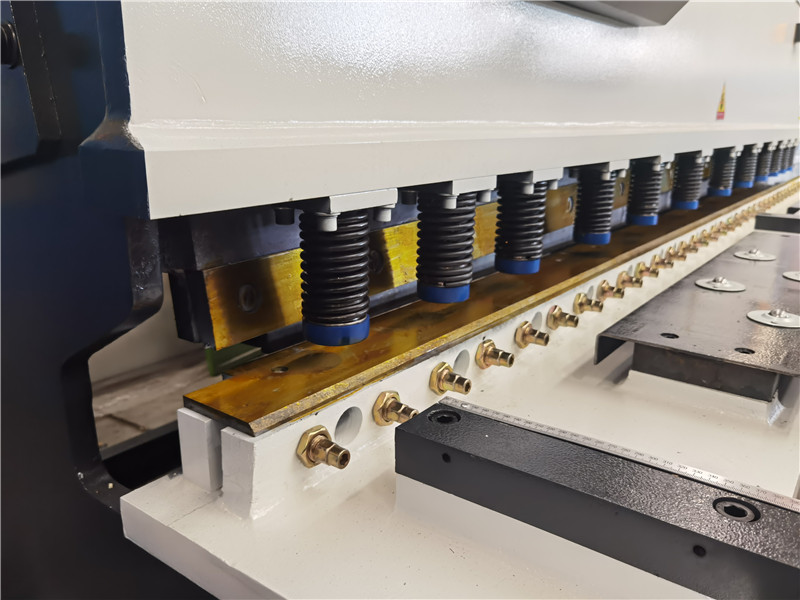

2) The gap between knife plates shall be adjusted according to the thickness of the plate, but shall not be greater than 1/30 of the maximum plate. The knife plate shall be fastened firmly, and the upper and lower knife plate surfaces shall be kept parallel. After alignment, manual turning shall be used for inspection to avoid accidents.

3) The blade of the knife plate shall be kept sharp. If the blade becomes blunt or cracks, it shall be replaced in time.

4) During shearing, the pressing device shall firmly press the sheet, and it is not allowed to shear when the pressing is not tight.

5) For equipment with hydraulic device, other hydraulic valves except throttling valve shall not be adjusted without permission.

6) . The thickness of the plate sheared by the hydraulic swing plate shears shall be determined according to the Curve of the Relationship between the Ultimate Strength of the Plate and the Plate Thickness.

- After work, the upper cutter plate shall be placed at the lowest position.

Before operation, wear tight protective clothing with cuffs fastened. The hem of the jacket cannot be opened. Do not wear, take off or change clothes near the running machine tool, or wrap around the body to prevent the machine from being twisted. Safety helmet must be worn. Braids should be put into the helmet. Skirts and slippers are not allowed.

The operator of the shear must be familiar with the main structure, performance and use method of the shear.

Plate shears are suitable for cutting various steel plates, copper plates, aluminum plates and non-metallic material plates with the thickness of the machine tool’s rated value, and must be free of hard marks, welding slag, slag inclusion and welding seams. Excess thickness is not allowed.

How to use the shearing machine: adjust the clearance of the blade according to the thickness of the material to be sheared; Adjust the profile or clamp according to the width of the material to be cut; Before the operation of the plate shears, conduct 1-3 idle strokes, and then conduct the shearing work after it is normal.

In case of abnormal operation of the machine during use, the power supply shall be cut off immediately and the machine shall be shut down for inspection.

When adjusting the machine tool, the power must be cut off. When moving the workpiece, pay attention to the safety of hands.

All parts of the plate shear shall be lubricated regularly. The operator shall fill lubricating oil once per shift, and the mechanic shall fill lubricating oil once every half a year for the rolling bearing.

Notes for use

- Start the plate shearing machine for idling for several cycles to ensure that under normal conditions, try to shear plates of different thicknesses from thin to thick. Make sure that the user is familiar with the performance of the shear.

- Different blade clearances must be adjusted for different plate thicknesses during shear test. If the corresponding blade clearance is not adjusted, the blade durability will be affected.

- Switch on the pressure gauge switch of the plate shearer during shearing, observe the pressure value of the oil circuit, and the pressure shall be less than 20MPa when shearing 12mm plates. The pressure of this remote pressure regulating valve No9 is set at 20-22MPa when it leaves the factory. The user must comply with this provision. It is not allowed to increase the pressure for the material surface beyond the specified value, causing damage to the machine.

- Sound balance during operation. If the shearing machine has noise, it shall be stopped for inspection.

- During the operation of the shear, the temperature of the oil tank is less than 60 ° C, and if it exceeds 60 ° C, shut down the machine for rest.