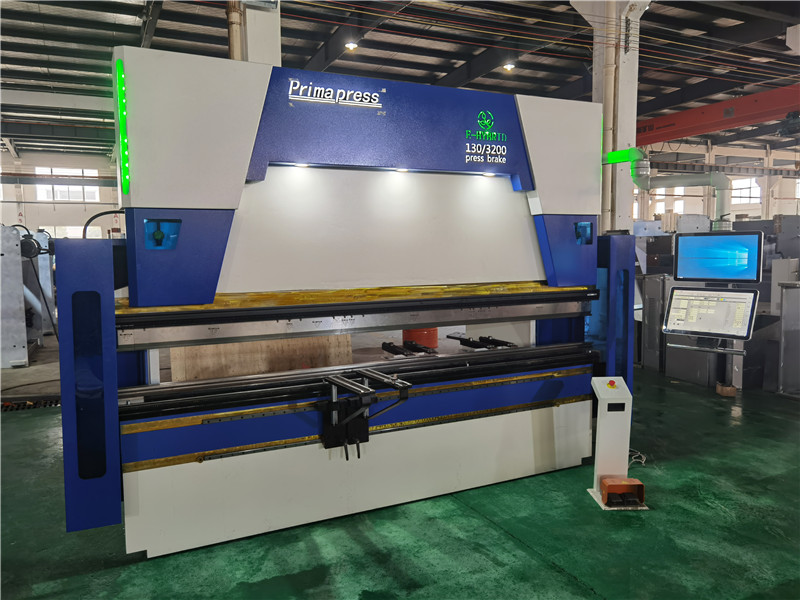

Method of bending circular arcs with a cnc press brake bending machine

There are generally several methods for bending arcs in a cnc press brake bending machine:

- Using molds:

A common method is to use specially designed arc molds. This type of mold typically includes an upper mold and a lower mold, with the upper mold having a curved blade and the lower mold providing support. By adjusting the position and angle of the upper and lower molds, the circular arc bending operation of the sheet metal can be achieved.

- Utilizing multi-stage bending:

If the CNC cnc press brake bending machine does not have a dedicated arc mold, it can approach the arc shape through multi-stage bending. Divide the entire arc into multiple small segments and perform bending operations on each segment. By controlling the bending angle and position of each small segment, it is possible to achieve an approximate shape of an arc.

- Use special cutting tools:

Some CNC cnc press brake bending machines can use special cutting tools to achieve circular arc bending. These cutting tools are usually designed based on the shape of the arc to be bent, and can complete the formation of the arc in one bend.

It should be noted that when performing circular arc bending, it is necessary to set reasonable parameters based on specific sheet materials, thickness, radius, etc., and obtain the desired circular arc shape through experiments and adjustments. Meanwhile, ensuring the rigidity and accuracy of the machine tool, as well as the quality and adaptability of the mold or tool, is also crucial for achieving high-quality arc bending results.