Kazakhsta order Primapress smart cnc folding machine flexible bending center machine

Mr.R is a young Customer from Kazakhsta. He is engaged in sheet metal processing enterprises. The Involve industry is very wide. Mr.R very interested in the Panel Bending Machine . we first time discuss this machine last year ,Then we communicated through WhatsApp. He need bending the product ,the material is Corbon Steel, a board that needs to be processed with a maximum board, is 2mm thickness , Then I recommended him Second Generation Prima HS 2500 Smart Folding Machine with the Press Arm 13 Axis.

when I discussed with Mr. R,first showed The production efficiency of our machine test videos for bend a panel. This speed can replace the traditional bending machine, and a machine can replace at least 2 workers.

It is a benchmark product that has entered automated production in the sheet metal manufacturing industry.

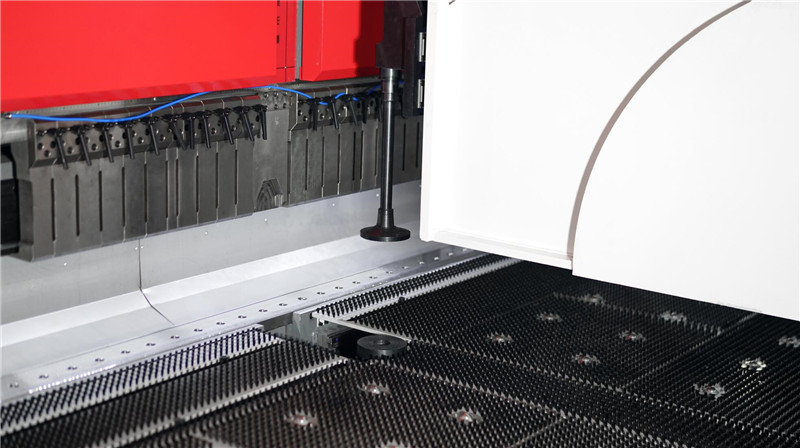

The bending speed is three times the CNC bending machine, reaching 0.5 S/times, and the full servo control can control the product accuracy within 3s.

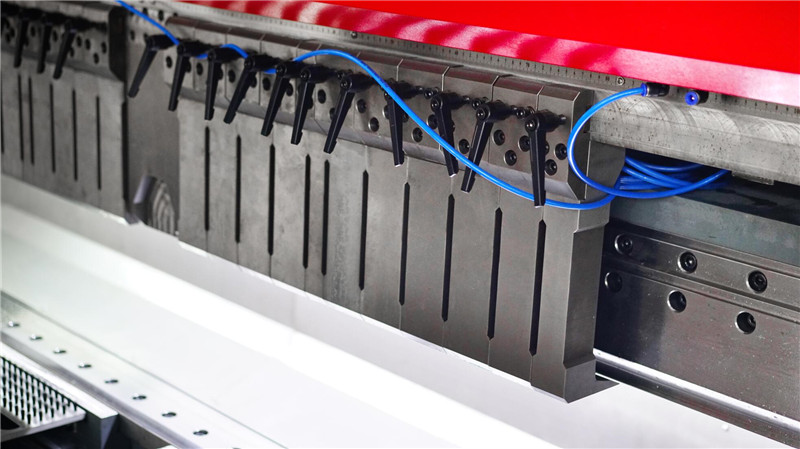

The whole machine is designed and produced in accordance with the standards of high -precision machine tools, and the main bed adopts a high label

Casting, both casting and welded parts have been strictly processed.

The machine tool is integrated, and finally uses a high -precision detector to strictly control the long -term operation of the machine

Accuracy, stability and high rigidity of smart cnc folding machine flexible bending center machine

The advantage of this machine is The flexible bending center focuses on solving various complicated sheet metal and bending problems in metal forming. Through multi-axis concurrent linkage, sheet metal operations are automatically completed, and the dependence on molds and labor is resolved from a technical perspective, which effectively improves production efficiency and reduces production costs.

Easily realize the arc, press dead edge, back shape, closed shape and other complex sheet metal bending requirements.

2500 functional configuration

◆ high-strength plate-welded body

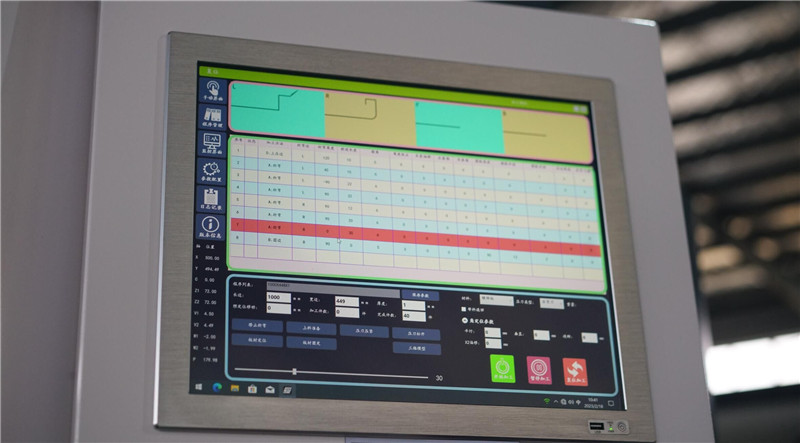

◆ 13-axis linkage control system

◆ pressure arm P-axis pressure adjustment system

◆ speed regulation instruction

◆ Advanced Directive

◆ on and down the dead side command

◆ Five-axis fully automatic positioning system

◆ separable locator

◆ fully automatic lubrication system

◆ off-load visualization system

◆ C axis, A axis synchronization system

◆ simulated bending visual system

◆ servo torque feedback system

◆ joint robotic arm docking system

◆ acting frame robotic arm docking system

◆ automated production line interface

◆ Internet of Things interface

◆ cloud operation and maintenance management interface

The flexible bending center can be widely used in the field of steel cabinet shells (file cabinets, tool cabinets, outer shields, electrical cabinets, communication cabinets, gas cabinets, water meter cabinets…), kitchen utensils (refrigerators, air conditioners, stoves…) , Furniture, ventilation, refrigeration, purification, door industry, decoration, elevator and other related metal forming fields. Primapress can manufacture the 1400mm and 2000mm , and 2500mm model.

After several months of communication, Mr. R said that he was ready to purchase our machine Second Generation Prima HS 2500 Smart Folding Machine with the Press Arm 13 Axis,and signed a contract with our Primapress company。Our Prima press company welcomes more customers to consult our Panel Bending Machine. We must show our customers the best machines and services to our customers!