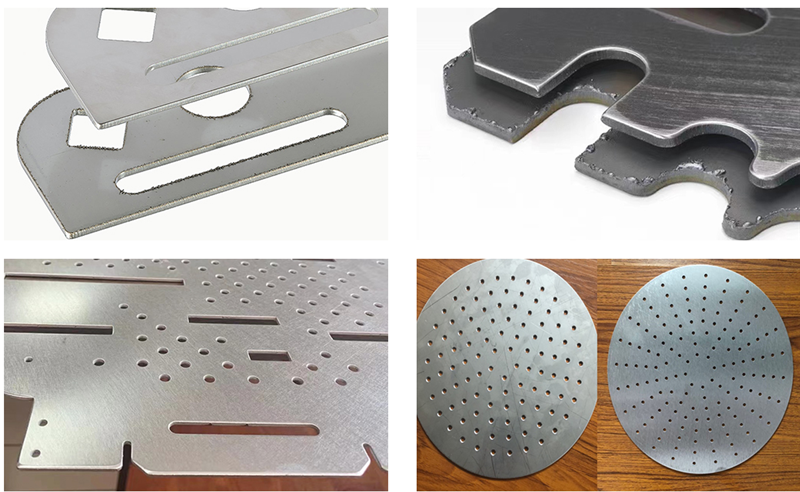

Introduction to Automatic metal plate metal plate deburring and polishing machine belt sander machine

plate deburring and polishing machine belt sander machine Basic parameters:

- Scope of equipment application: Suitable for laser cutting, stamping cutting, flame cutting plasma cutting, machining and other metal plate slag and burr removal, surface pre grinding, wire drawing, edge chamfering and other processes

- Four or six sets of roller brushes, adjacent to each other to form a positive and negative rotation direction, can ensure that the abrasive fully contacts each position of the product, thereby presenting a perfect processing effect.

- Equipment function: Pre grinding, wire drawing, polishing, scratch removal, deburring, chamfering and rounding off of workpiece surfaces such as laser cutting, plate cutting, stamping cutting, water knife cutting, plasma cutting, etc

- plate deburring and polishing machine belt sander machineEquipment combination: wide sand belt+universal rolling brush single or multiple combined structures

- Equipment processing width: 600mm, 800mm, 1000mm, 1300mm, 1600mm

- Equipment processing thickness: 0.5-60mm

- Conveying and feeding speed: 0.5-8m/min (variable frequency adjustable)

Variable frequency adjustable rolling speed

Variable frequency adjustable rotation speed

- Optional feeding method:

(1) Strong permanent magnet adsorption conveying material (suitable for carbon steel workpieces. Workpiece size ≥ 10mm × 10mm)

(2) Vacuum negative pressure adsorption conveying and feeding (suitable for stainless steel plates, copper plates, aluminum plates, etc. that are not magnetically adsorbed. Workpiece size ≥ 50mm × 50mm)

- Adjust the machining parameters on the CNC PLC touch screen of the entire machine.

- Equipped with wet vacuum cleaners to achieve environmentally friendly production.

- plate deburring and polishing machine belt sander machinespecifications:

| Processing width

Working thickness Feeding method/conveyor way Feeding speed/conveyor speed Broadband Belt Speed Brush plate rotation speed

Brush rotation speed |

300/650/1050/1300/1800mm

0.3-100mm Vacuum adsorption/magnetic adsorption/pressure roller 0.5-6m/min 12m/s-20m/s 60-120r/min 600-1450r/min

|