Intelligent flexible bending centers replacing ordinary cnc press brake bending machines?

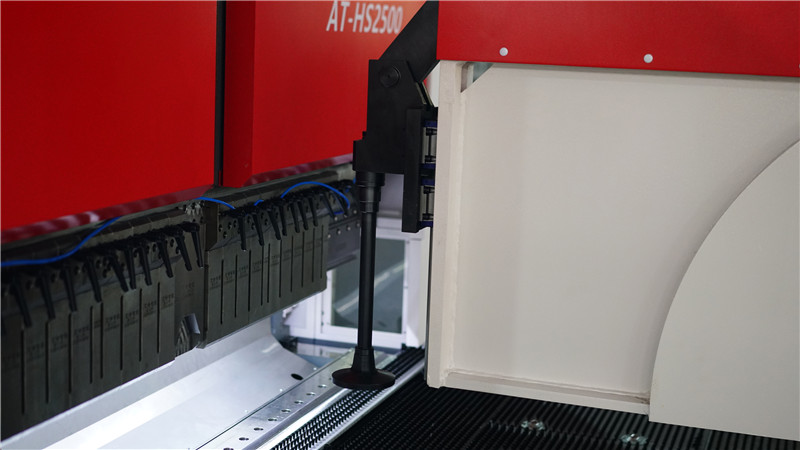

The main advantages of intelligent flexible bending centers compared to traditional cnc press brake bending machines are as follows:

- Speed

The fastest fully automated bending process in the intelligent flexible bending center can reach 0.2 seconds per tool, greatly reducing the cycle time of multi sided and multi pass bending, which is more than three times the speed of traditional CNC cnc press brake bending machines. The more edges and more complex the workpiece, the greater the speed advantage.

Traditional CNC cnc press brake bending machines require skilled workers to hold the workpiece for positioning and bending, and each edge needs to be repositioned, resulting in low efficiency.

- Labor

The intelligent flexible bending center has low technical requirements for workers. Ordinary workers can take up their posts after training, without the need to hire experienced and skilled workers. At the same time, the bending process is completely automated, greatly saving labor and reducing the labor intensity of workers. Traditional CNC cnc press brake bending machines often require multiple people to complete large-sized workpieces, while intelligent flexible bending centers only require workers to place the workpiece on the workbench, and the equipment automatically completes positioning, which is truly time-saving and labor-saving.

- Security

The intelligent flexible bending center does not require manual holding of workpieces, and the bending process is completely automated, greatly reducing the safety hazards caused by worker misoperation.

- Usability

The intelligent flexible bending center adopts graphic visualization programming. Workers only need to input bending data based on the workpiece, and the system automatically generates bending instructions without the need for code programming. Ordinary workers can master it in 2 hours. Traditional CNC bending centers require workers to master complex programming skills and memorize the bending sequence of each edge during the bending process, which is difficult and has a high error rate.

- Consistency

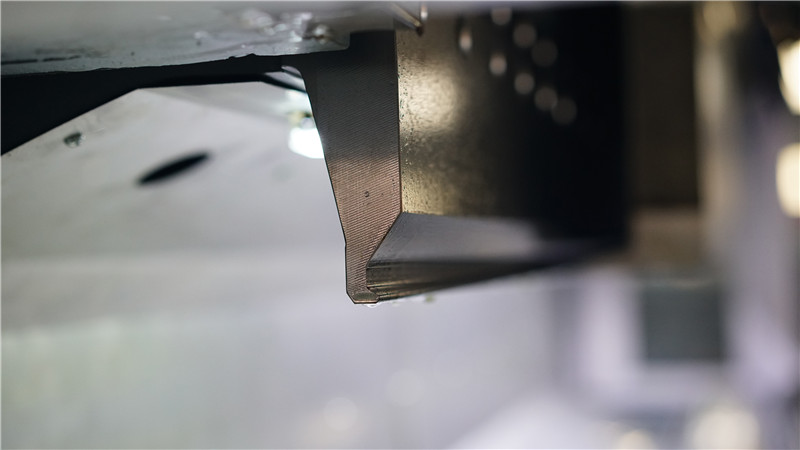

The intelligent flexible bending center can achieve automatic positioning of sheet metal, with high positioning accuracy and higher consistency of formed products, making it more suitable for mass production. The traditional CNC bending center has low accuracy in positioning and may result in dimensional errors due to multiple positioning.

- Automation

The intelligent flexible bending center reserves rich interfaces for easy connection with upstream and downstream production lines. It can be docked with a robotic arm to achieve automatic integrated loading and unloading. Paired with a self driving robotic arm and an intelligent flexible bending center in the same control system, the collaborative efficiency is higher; Replacing a workpiece does not require maintaining two sets of programs, only changing the bending center program and automatically generating a robotic arm program, resulting in higher flexibility.