How to solve the aging problem of metal fiber laser cutting machine

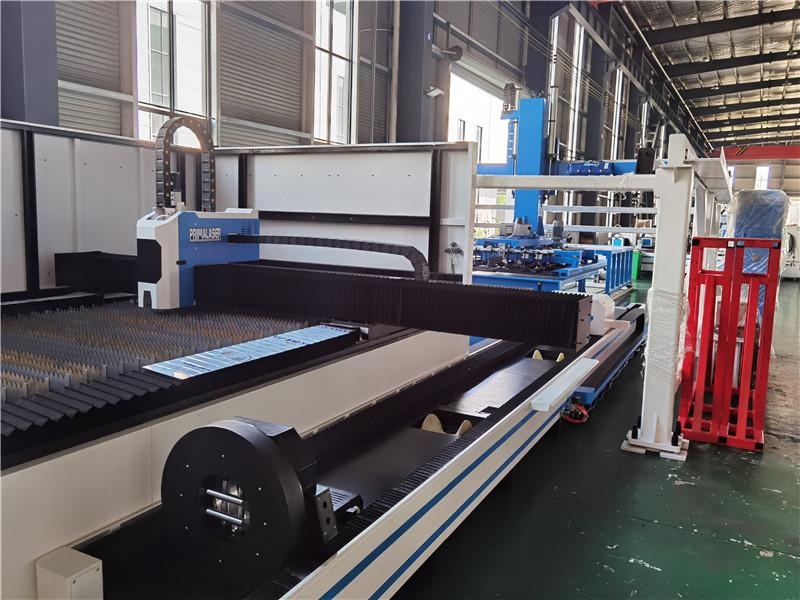

Among the components of the metal fiber laser cutting machine, the fiber laser is a vulnerable component, so both the operator and the business owner must pay attention to it in daily use.

So how to slow down the aging of the metal fiber laser cutting machine? In fact, it is like this. There are roughly two reasons for the power reduction of the fiber fiber laser cutting machine:

One, the machine needs to check and maintain the external optical path of the fiber laser generator regularly. In fact, the power of the metal fiber laser cutting machine will decrease

after a period of continuous use. When the power drops to affect production, it is necessary to maintain the fiber laser and the external optical path. When the maintenance is completed, the cutting capacity will be restored to the level when leaving the factory.

Maintenance and maintenance of fiber laser: Fiber laser is the head component of metal fiber laser cutting machine. Its quality directly affects the performance of the metal fiber laser cutting machine. If its quality itself has problems, it will speed up the metal fiber laser cutting machine. The rapid aging. Therefore, choosing a high-quality fiber laser is the key point. In addition, the maintenance work in the later period is also very important. Just like a person, no matter how good the skin is, it needs to be maintained. Only by doing enough daily care and maintenance can you delay aging and make your youth longer. After the fiber laser works for a period of time, The power drop is inevitable. Therefore, the maintenance of fiber lasers can be done as much as possible to keep the function of the fiber lasers at a standard and postpone the aging problem of the fiber lasers.

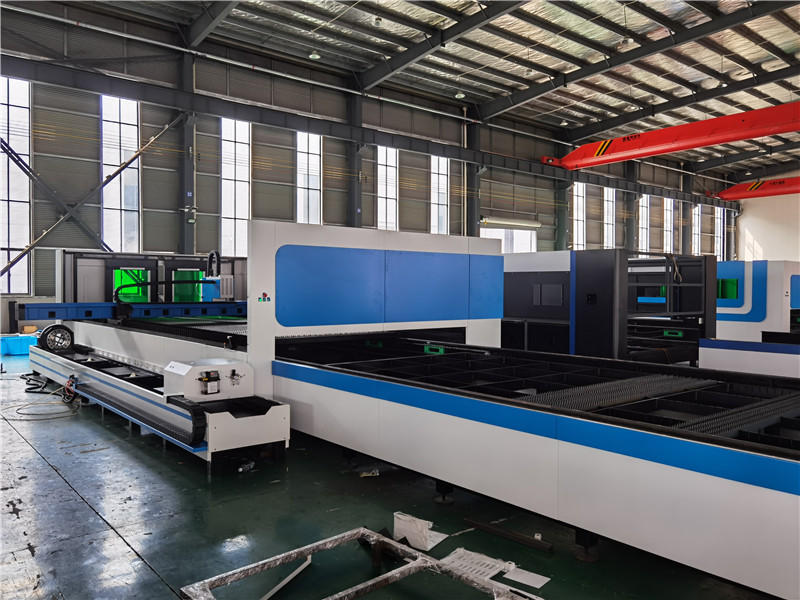

Secondly, the environment and conditions of the production site have a great influence on the power of the metal fiber laser cutting machine. Such as the quality of compressed air.

There is a lot of dust and smoke at the production site, and some users put paint spraying operations near the fiber optic laser cutting machine, which will affect the power of the fiber optic laser cutting machine, and then cause the cutting quality and cutting ability to decline.

The use environment of the metal fiber laser cutting machine: the use environment of the metal fiber laser cutting machine (such as temperature, dust) The metal fiber laser cutting machine has certain requirements for the temperature of the studio, and if the temperature is too high, it will cause crashes and slow response. Too low temperature can cause damage to air pipes and cables, and easily cause breakage and air leakage. Therefore, controlling the temperature of the working environment of the metal fiber laser cutting machine is one of the key factors to delay the aging.

In addition, the metal fiber laser cutting machine will generate a large amount of metal dust during operation. These dust, dust and smoke in the air adhere to the equipment, which will increase the wear and tear between the various parts of the equipment, and the attached dust will also affect The transmittance of the focusing lens indirectly affects the cutting accuracy of the metal fiber laser cutting machine.

The aging of metal fiber laser cutting machines is an unstoppable trend. How to protect and delay aging is a key issue. We hope that users will do a good job of maintenance in their daily work.

In addition, if there is any problem in the work of the equipment, it must not be ignored, and it must be dealt with in time to keep the equipment in good condition.