How to select a sheet metal cnc servo press brake bender machine

The workpiece is the first factor to consider, and the key is to purchase a machine that can complete processing tasks with the shortest workbench and the smallest tonnage. The length of the processed parts is crucial for determining the specifications of the new equipment. Careful consideration should be given to the material grade of the processed parts, as well as the maximum processing thickness and length. Correct selection can greatly reduce procurement costs;

The second one is deflection, as shorter machines require less gasket adjustment to produce qualified parts. Reducing gasket adjustment also shortens preparation time. So, the material grade is also a key factor, and a machine tonnage table can be obtained from the manufacturer at any time, displaying the estimated tonnage required for different thicknesses, materials, and lengths;

The third factor is the bending radius. In order to choose the lowest tonnage specification, it is best to consider bending larger than the material thickness and use the free bending method as much as possible. When the bending radius is large, it generally does not affect the quality of the finished workpiece and its subsequent use;

The fourth factor is the bending degree. The bending accuracy requirement is a factor that needs careful consideration. It determines whether to choose a CNC (Computer Numerical Control) sheet metal cnc servo press brake bender machine or a manual sheet metal cnc servo press brake bender machine. If the bending accuracy requirement is ± 1 ° and cannot be changed, it is necessary to focus on the CNC machine. In addition, CNC sheet metal cnc servo press brake bender machine is ready for rapid mold installation. When it is necessary to bend many small batch parts, this factor cannot be ignored;

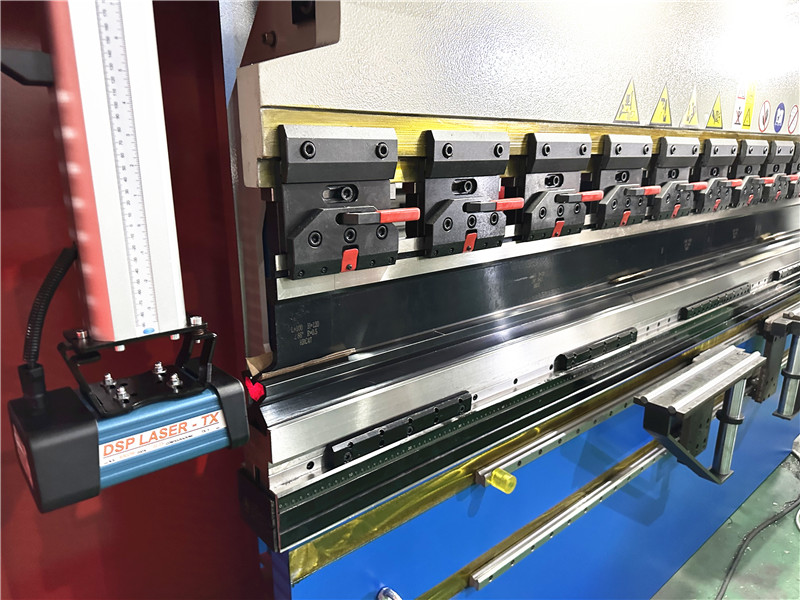

The fifth factor is that the variety of molds may not be suitable for new equipment. It is necessary to check the wear status of each mold by measuring the length from the front end of the convex mold to the shoulder and the length between the shoulder of the concave mold. It is better to use the precision grinding die for CNC sheet metal cnc servo press brake bender machine, and the conventional die for manual sheet metal cnc servo press brake bender machine.