Hand-held sheet metal laser welding machine and argon arc welding machine use cost

Principle comparison:

Sheet metal laser welding machine is an application of laser thermal processing, which is a kind of high-energy beam welding. Laser equipment welding is welding using

a laser beam focused by a high-power coherent monochromatic photon stream as a heat source. The advantage is that it does not need to be carried out in a vacuum,

and can carry out precise energy control, so that the welding of precision devices can be realized. It can be applied to many metals, especially to solve the welding of some

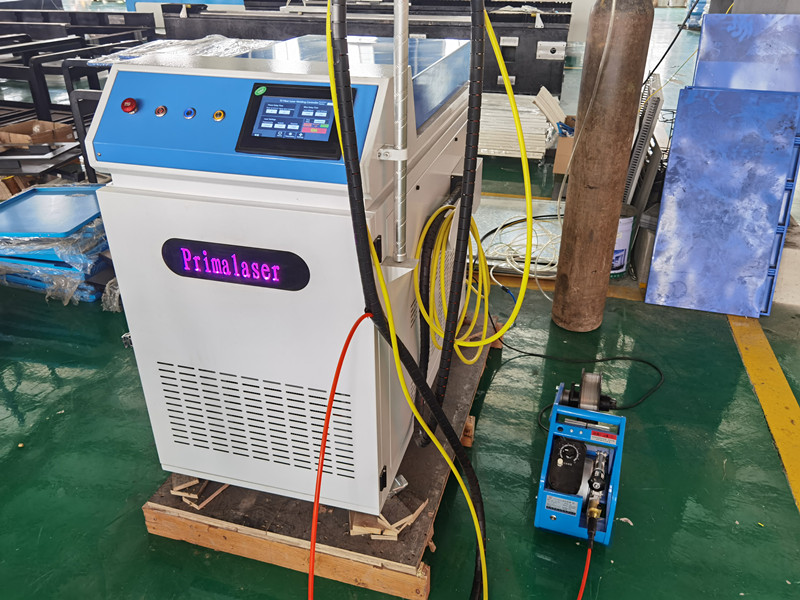

difficult-to-weld metals and dissimilar metals. It has been widely used for mold repair. The current portable handheld metal sheet laser welding machine is popular

because of its relatively small size and price advantage!

The argon arc welding machine is a kind of arc welding, which mainly uses the arc burning between the continuously fed welding wire and the workpiece as the welding

heat source, and the gas shielded arc sprayed from the torch nozzle realizes the purpose of welding. . At present, argon arc welding is a commonly used method, which can

be applied to most major metals, including carbon steel and alloy steel. MIG welding is suitable for stainless steel, aluminum, magnesium, copper, titanium, zirconium and

nickel alloys. The cost is relatively low. It is often used for mold repair, but it has disadvantages such as large welding heat affected area and large solder joints.

It is currently used in precision mold repair It has been gradually replaced by sheet metal laser welding machines.

Cost comparison between handheld sheet metal laser welding machine and argon arc welding machine:

The difference between a handheld metal sheet laser welding machine and an argon arc welding machine. The argon arc welding machine is a type of arc welding.

It uses the arc burning between the continuously fed welding wire and the workpiece as the heat source, which is sprayed from the torch nozzle Gas-shielded arc welding

has disadvantages such as large welding heat-affected area and large welding spot. Argon arc welding machine uses non-consumable electrodes and shielding gas.

It is often used to weld thin workpieces, but the welding speed is slower and the heat input is higher than that of metal. The sheet metal laser welding machine is much

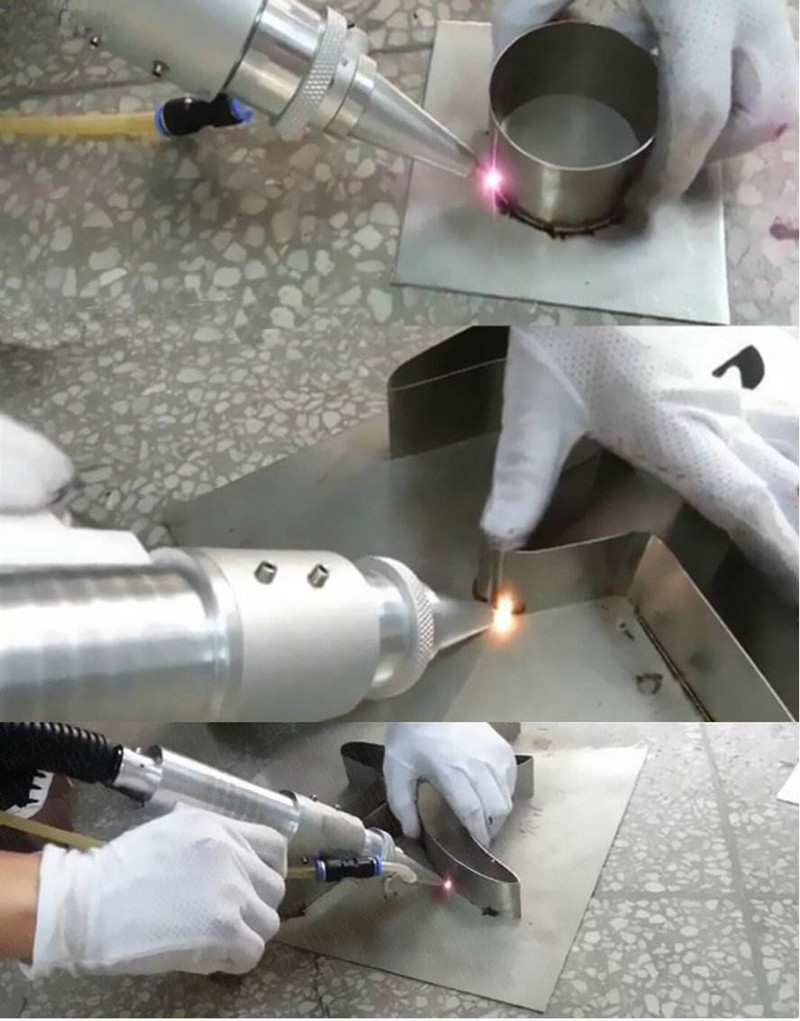

larger and is prone to deformation; while the metal sheet laser welding machine welding seam is characterized by a small heat-affected zone, a narrow weld seam, a fast

welding seam cooling rate, a small change in the performance of the weld metal, and a hard weld seam. . At present, the precision welding of argon arc welding machines

has been gradually replaced by hand-held sheet metal laser welding machines.

For welding thin-walled materials, it is better to use a sheet metal laser welding machine to weld thick materials. If there is no high requirement for welding accuracy

and welding speed, it is relatively more cost-effective to use an argon arc welding machine, but if you pursue good welding For the effect, it is better to use a

sheet metal laser welding machine.

Regarding the use cost of the handheld sheet metal laser welding machine and the argon arc welding machine, it must be judged by the welding effect that needs to be achieved.

The sheet metal laser welding machine does have the incomparable welding speed and welding accuracy of the argon arc welding machine.