![press brake]](https://www.china-prima.com/wp-content/uploads/2022/11/press-brake-420x280_c.jpg)

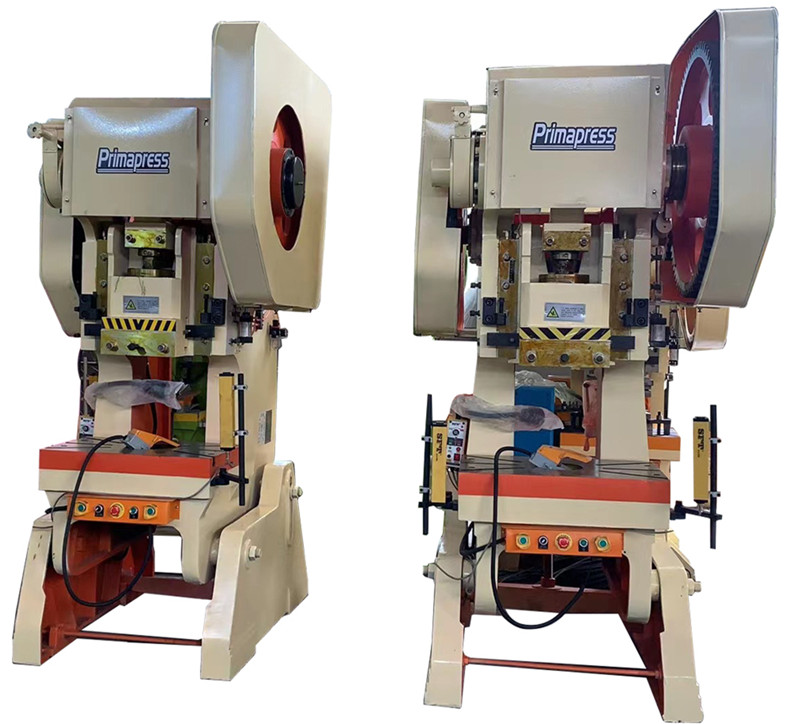

Functional characteristics and sales of open type fixed table punch press stamping machine

Tilting punch press stamping machine

Equipment for shearing, blanking, punch press stamping machineing and forming of various metal sheets

The tilting punch press stamping machine can realize cold stamping processes such as shearing, punch press stamping machineing, blanking, bending and shallow drawing forming. Manual feeding during operation, and single machine automation can be realized when the feeding device is configured additionally. Its structural characteristics are: the body is made of high-strength cast iron, and the single disc pneumatic block friction clutch and brake are used. Its trouble free service life is much longer than that of similar products. The sliding block is equipped with a collapse type safety device. When the machine tool is overloaded, the safety device will be collapsed first, thus ensuring that the whole machine will not be damaged.

Functional features

The working principle, use and scope of use of the tilting punch press stamping machine press JB23 open type double column tilting punch press stamping machine press takes the crank connecting rod as the working mechanism. This press is a universal press for sheet metal stamping. It can be used for cutting, punch press stamping machineing, blanking, bending, shallow drawing, forming and other cold stamping processes. The body of the press can be tilted by 25 ° to facilitate the sliding of finished stamping products or waste materials from the die. Single stroke or continuous stroke can be obtained by controlling the operating mechanism of the press with an electric appliance. When the automatic feeding mechanism is installed, semi-automatic continuous stamping can be carried out. When selecting the stamping equipment, it shall be selected according to the data given in the pressure curve. During stamping, it shall not exceed the strength range of the pressure curve. The press will be continuously improved in the production process. Some structures may be inconsistent with the contents of this manual, but the adjustment and use will not be affected, so no further notice will be given. In order to ensure the safety of the press in use, the contact of the travel switch must be flexible and reliable. [Main functions and characteristics of tilting punch press stamping machine: universal forging equipment, which is applicable to various metal sheet cutting, blanking, punch press stamping machineing, forming, bending, shallow drawing and other stamping processes. It is one of the main equipment in stamping production in various industrial departments.

It was found that some customers had misunderstandings about deep throat punch press stamping machine and tilting punch press stamping machine.

Generally, deep throat punch press stamping machine and tilting punch press stamping machine are distinguished from each other in the following aspects.

Speed: the speed of tilting punch press stamping machine is generally below 200 times, and that of deep throat punch press stamping machine is generally within 200~1000 times.

In terms of control: the ordinary ones are manual and foot operated. The deep throat punch press stamping machinees are all numerical controlled and fully automatic feeding.

In terms of precision: there are general and precision in general precision, and deep throat punch press stamping machinees are precision.

The 63t open fixed table mechanical punch press stamping machine JC21-63T adopts a steel plate welded body, which has good rigidity and beautiful appearance. It adopts a combined pneumatic friction clutch and brake, which are balanced, sensitive, and low noise. The slide block is equipped with a collapse block type overload protection device to protect the safety of parts and molds. It uses a pneumatic safety dual valve control, and can be equipped with an air cushion device, an automatic feeding device, and a photoelectric protection device.

63t open fixed table punch press stamping machine JC21-63T Performance characteristics:

- Straight body design, balanced stress, no deformation, strong rigidity;

- Ultra high enclosed height and large mold installation space;

- The slider is guided by a rectangle with six sides, high precision and good stability;

- The external supporting extra large frame improves the installation stability and safety of the 63t open fixed table punch press stamping machine;

- Built in oil circuit, circuit, beautiful and clean, more safe and reliable;

- The button switch is operated by both hands and complies with the national safety standard for press;

- It is easy to operate and maintain, and is suitable for all kinds of heavy duty stamping and hot die red stamping.

Technical process description of 63t open fixed table punch press stamping machine JC21-63T:

- The fuselage is welded with steel plates, and is subject to vibration aging treatment to eliminate internal stress and prevent deformation;

- The crankshaft is made of 45 # iron, forged and refined;

- Copper parts are used for body bearing bush and connecting rod bearing bush;

- The working key is made of 40Cr forged and quenched;

- The connecting rod is made of ductile iron, which increases the strength;

- The slider is enlarged.