Features and application scope of metal pneumatic punch press machine

Features of metal pneumatic punch press machine:

- Compressed air is used as the power source, and it is easy to operate and simple in structure.

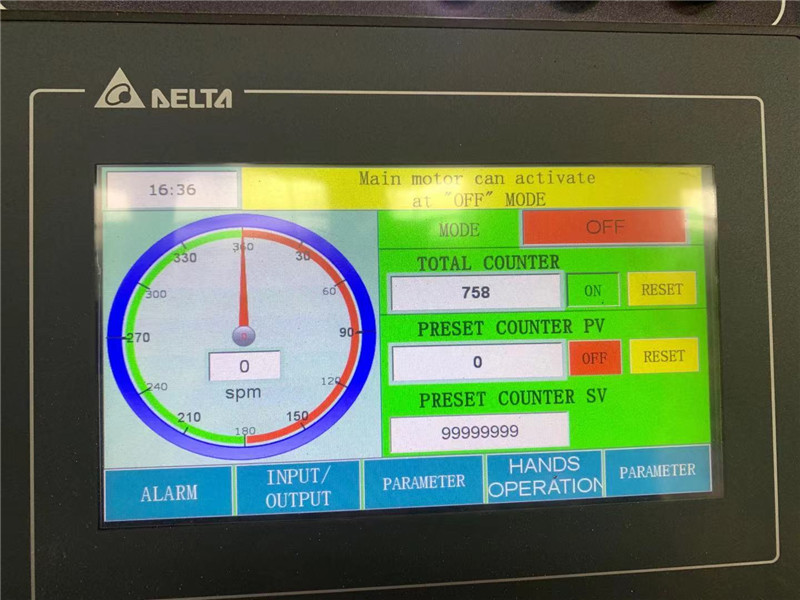

- Using a microcomputer control system, the mode can be selected from manual, semi-automatic and fully automatic. Heating mold, temperature control and pressure sensor can be added. Simple structure.

- Equipped with anti-rotation guide rods and guide plates, with high precision, which can adapt to high-speed punch press machineing.

- The height, speed, stroke, pressure and stamping time can be adjusted arbitrarily according to different products or molds.

- There is no noise generated by the hydraulic system during standby, which can save power consumption and reduce production costs.

- Two-hand control or foot pedal mode can be selected. Ensure the personal of the operator.

Application range of metal pneumatic punch press machine

- Metal punch press machineing industry: metal pneumatic punch press machineing machines are widely used in metal punch press machineing industry, and can be applied to the punch press machineing field of various metal and non-metal pipes and plates.

- Machinery industry: applicable to the processing and production of stamping parts, stamping processing, metal stamping parts, metal stamping parts, automobile stamping parts, drawing parts, metal drawing parts, and stamping sheet metal parts in the machinery industry.

- Household products: most of the furniture products in daily life are processed and produced by metal pneumatic punch press machinees, such as electronics, communications, electrical appliances, lighting, toys, chassis, furniture, sports equipment, barbecue tableware hardware, lighting hardware, electronic hardware , Chassis cabinets, kitchen utensils, hinges, split pins, spring pins, pliers, dried fruit pliers, packaging materials, stickers, mobile phone films, gaskets, cushions, aluminum parts, terminals, speaker nets and other daily necessities.

- Road traffic: In particular, the production of auto parts is inseparable from metal pneumatic punch press machinees, transportation supplies, protective equipment, automobiles and motorcycles and accessories communication products.

- Office supplies: power cabinets, ATM shells, air-conditioning parts, printers, copier racks and various sheet metal.

What is the difference between a high-speed punch press machine and a traditional punch press machine

Different classification methods:

- According to the general speed, the low-speed punch press machineis about 110 speed, the high speed is about 200~1100 times/min, and the ultra-high speed punch press machineis more than 1100 per minute.

- According to the control mode, it is divided into ordinary punch press machineing machine and high-speed punch press machineing machine.

CNC punch press machineing machine: short for digital control punch press machineing machine, it is an automatic machine tool equipped with a program control system

High-speed punch press machineing machine: punch press machineing to about 200-1100 times per minute

- The precision of the high-speed punch press machineing machine and the precision requirements of the required mold are relatively high, so the cost is relatively high.

- High-speed punch press machineing machine has strong automation and practicality.