Features and advantages of cnc press brake bending machine follow-up support machine

cnc press brake bending machine follow-up support machine is a semi-automatic tool that assists the bending worker to do the upturning action during the bending process. The servo bending follow-up car has no requirements on the cnc press brake bending machine system and the pressure spindle. The floor-type follow-up front support device has an independent control system, which can be moved and used in conjunction with any bending equipment on the production site. Independent structure, no need to modify the mechanical parts of the cnc press brake bending machine. Independent electrical control system, man-machine interface, programmable or manual operation. Cooperate with CNC cnc press brake bending machine to quickly form semi-automatic processing, save labor, fast and flexible, mass production, and have good economic benefits.

Features

- Can be equipped with all brands and models of up-moving press brakes (hybrid hydraulic press brakes, electro-hydraulic servo press brakes, torsion axis press brakes).

- The main body is an independent structure, no need to change the mechanical parts of the cnc press brake bending machine, and the base is a Foma wheel structure that can be moved at any time.

- Universal balls are installed on the support table, which is convenient for the movement of the workpiece, and the direction of rotation is convenient for bending the workpiece.

- The height of the pallet can be fine-tuned up and down to facilitate the installation of molds of different heights.

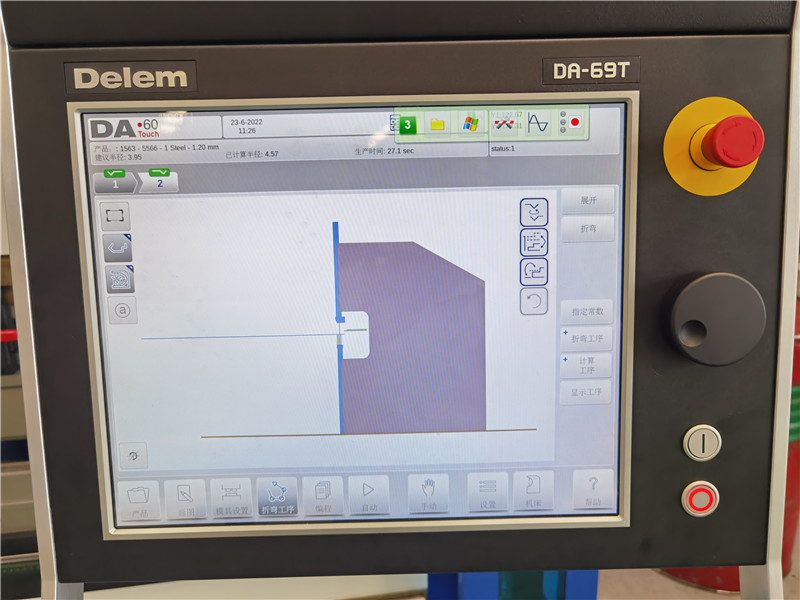

- Independent PLC electrical control system, using magnetic scale to feed back information to the computer, and the computer controls the closed-loop servo motor to do follow-up action.

- The follow-up turning speed can be adjusted according to different plate thicknesses, no need to change the control system of the cnc press brake bending machine, and no programming is required for standard bending; human-machine interface, programmable or manual operation.

- There is no need to modify the cnc press brake bending machine, only a displacement sensor needs to be installed on the slider of the cnc press brake bending machine, and it can be used after connecting to the incoming line interface of the cnc press brake bending machine, avoiding the risk of failure caused by modifying the electric box of the cnc press brake bending machineand taking the signal of the cnc press brake bending machine, It also avoids the work injury accident of the cnc press brake bending machine falling off the knife and pressing the operator’s hand due to the follow-up car interfering with the signal of the cnc press brake bending machine.

Application characteristics of floor-mounted servo follower in cnc press brake bending machine

- Compatibility

The floor-type bending follow-up front support device is a semi-automatic tool that assists the bending workers to do the upturning action during the bending process. The servo bending follow-up car is different from the follow-up device on the market. There are no requirements for the system and the pressure spindle, and the follow-up car has an independent control system, which can be moved and used in conjunction with any bending equipment on the production site.

During the first installation, adjust the interface of the cnc press brake bending machine and the parameters of the follow-up car. The next time you connect it, you only need to manually adjust the height of the car, and call up the follow-up parameters of the current cnc press brake bending machine, and you can use it. There is no need to purchase a cnc press brake bending machine equipped with a follow-up mechanism in order to improve the process, reducing the production input of the factory.

- Scalability

The size of the servo bending follower car can be customized according to customer requirements; it can also increase the profile support to expand the pallet width according to the requirements of the processed workpiece, and make personalized transformation.

The rotating pallet can be added to reduce the difficulty of the rotation direction of large-sized workpieces. One or two operators can easily and stably complete the bending process of large-scale panels. Universal bearings can be added around the pallet to reduce the difficulty of loading and unloading large-sized workpieces.

- High stability

The floor-type bending follower adopts a single-axis mechanical linkage method, which simplifies the control program on the one hand, and improves the mechanical stability on the other hand. At the same time, simple operation and fool-proof settings allow operators to get started quickly.

The servo follow-up cnc press brake bending machine and the bending forming machine can quickly form a semi-automation, which can quickly and flexibly proof and mass produce while saving labor, and has good economic benefits.