Factors to consider when buying a hydraulic ironworker combined punching and shearing machine

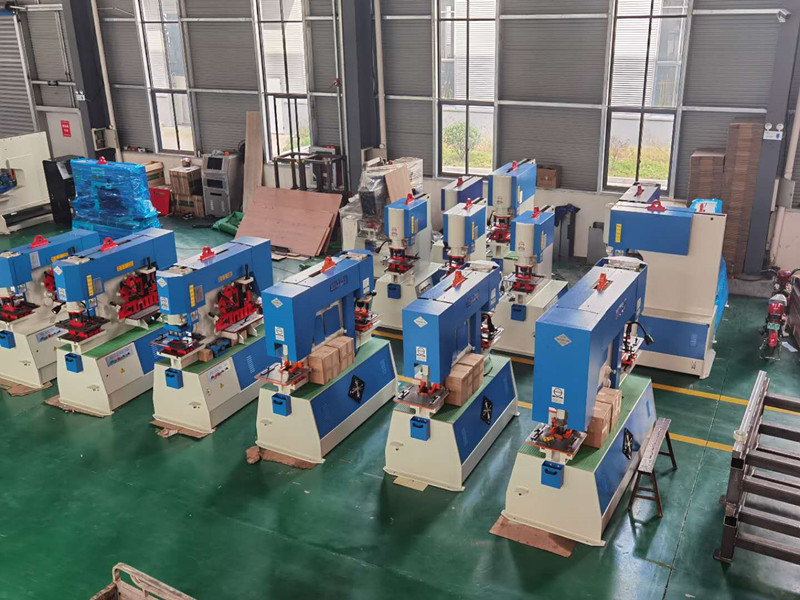

The hydraulic ironworker combined punching and shearing machine integrates various functions and can be used for various operations such as shearing, punching, and angle shearing of metal profiles. Today, I will show you some knowledge points about the multifunctional shearing machine. I believe that it will enable you to understand the shearing machine more clearly and operate it better in future use. The main details are as follows:

(1) The principle of the shearing machine is to drive the sliding plate equipped with the shearing blade to move up and down through the overlapping two-stage levers and sliders, and the fixed blade installed on the frame can complete the shearing of metal materials. Cutting and punching processing.

(2) The machine adopts electric power as the power source, and the punching and shearing of the machine is controlled by the foot switch, which can achieve 30 punching and shearing actions in one minute.

(3) We are also concerned about the types of metal profiles that can be processed. The hydraulic combined punching and shearing machine can punch and shear common steels such as angle steel, channel steel, steel plate, square steel, and I-beam. Shearing, corner trimming, die cutting and punching.

(4) Regarding the stations of the shearing machine, there are: punching station, angle steel shearing station, bar cutting station, plate shearing station, angle cutting station, etc., one machine is multi-purpose and easy to operate.

(5) The structure of the shearing machine is composed of the main parts such as the motor, the shield, the foot switch, the frame, and a number of punching and shearing parts.

Common functional characteristics of multi-functional combined hydraulic combined punching and shearing machine

- The machine is equipped with punching station, channel steel and angle steel shearing station, thick plate shearing station, round steel and square steel shearing station, and angle cutting station. Optional accessories such as punching large holes, channel steel punching, shutters and pipe corners are available.

- The combined hydraulic combined punching and shearing machine adopts the top processing technology in Europe. The frame is welded and quenched at high temperature, so that the frame has high rigidity and high strength; the tool is treated with special vacuum and high temperature to prolong its service life. number.

- The mechanical crankshaft transmission is selected, the whole machine has a reasonable layout, light weight, low noise, simple and reliable, and has an overload function.

- Standardize and equip five workstations. Independent work is not possible. The machine does not need any level adjustment, it can be used after it is put in place. Optional foot tower control system to add automatic punching, and shearing power.

As a kind of industrial equipment, the new multi-functional combined hydraulic combined punching and shearing machine has certain risks, so the operator must strictly operate in accordance with the mechanical safety operation rules. And only after passing the job can work. Before using the intelligent combined hydraulic combined punching and shearing machine, it is necessary to check whether the power supply voltage meets the requirements before closing the machine, and no one can operate it properly around the working range of the machine tool.