Elements of purchasing a metal plate fiber laser cutting machine

In enterprises that generally require metal plate fiber laser cutting machines, the price of metal plate fiber laser cutting machines should be one of the top priority factors for everyone. There are many manufacturers producing metal plate fiber laser cutting machines, but the prices vary greatly, ranging from tens of thousands of yuan to millions of yuan. It is difficult to decide which company to purchase equipment from. So, let’s talk about the differences between high priced cutting machines and low priced cutting machines. What exactly determines the price of metal plate fiber laser cutting machines.

- Servo motor: It is related to the cutting accuracy of the metal plate fiber laser cuttingmachine. Some manufacturers choose to import servo motors, some are servo motors from joint venture factories, and some are various miscellaneous motors.

- Laser lens: It is related to the power of the metal plate fiber laser cuttingmachine. It is divided into imported lenses and domestic lenses, and domestic lenses are divided into imported lenses and domestic lenses. There is a significant difference in price, as well as a significant difference in usage effectiveness and lifespan

- Laser tube: This is the heart of metal plate fiber laser cuttingmachines. Due to the high price of imported laser tubes, which are usually around tens of thousands of yuan, most domestic metal plate fiber laser cuttingmachines use domestic laser tubes. The quality and price of domestic laser tubes also vary. The service life of good laser tubes is usually about 3000 hours.

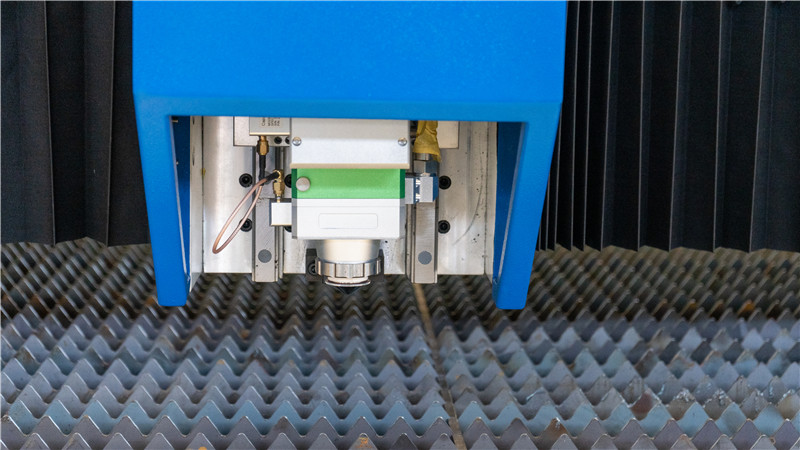

- Mechanical assembly quality: Some manufacturers use very thin iron plates to manufacture machine casings to reduce costs, which is usually not visible to users. However, over time, the frame may deform, affecting the cutting accuracy of the metal plate fiber laser cuttingmachine. A good metal plate fiber laser cuttingmachine should adopt a frame structure, welded with high-quality section steel, and made of high-quality cold-rolled steel plates for the casing. When a user purchases a machine, they can determine whether the quality is good or bad by checking whether the frame structure is being used and the thickness and strength of the outer iron sheet.

- Machine functions: Some people familiar with metal plate fiber laser cuttingmachines lament that the current configuration of metal plate fiber laser cuttingmachines has increased too much, and the price has decreased compared to a few years ago. How satisfying! But some people say that don’t be fooled by those shiny external things, if compared to the reliability and convenience of maintenance services, many new devices are not as “old three” as in previous years.

When purchasing a metal metal plate fiber laser cutting machine, not only should one pay attention to their own needs, but also choose the type of metal plate fiber laser cutting machine after analyzing the cutting process requirements and thickness. This is not to say that metal plate fiber laser cutting machines are better. For example, frequently cutting metal plates below 3mm and occasionally cutting thin plates around 10mm without high requirements for the cutting process, it is recommended to purchase a metal plate fiber laser cutting machine of approximately 1000 watts. If there are plates around 10mm that need to be cut, they can be processed by a third party. Firstly, many users have entered a misconception that the metal plate fiber laser cutting machine they purchase is “versatile” and can do anything. This is actually a big mistake, not only a waste of money, but also the operational efficiency of the equipment has not been well utilized.