Characteristics ,maintenance and configuration of hydraulic combined punching and shearing machine

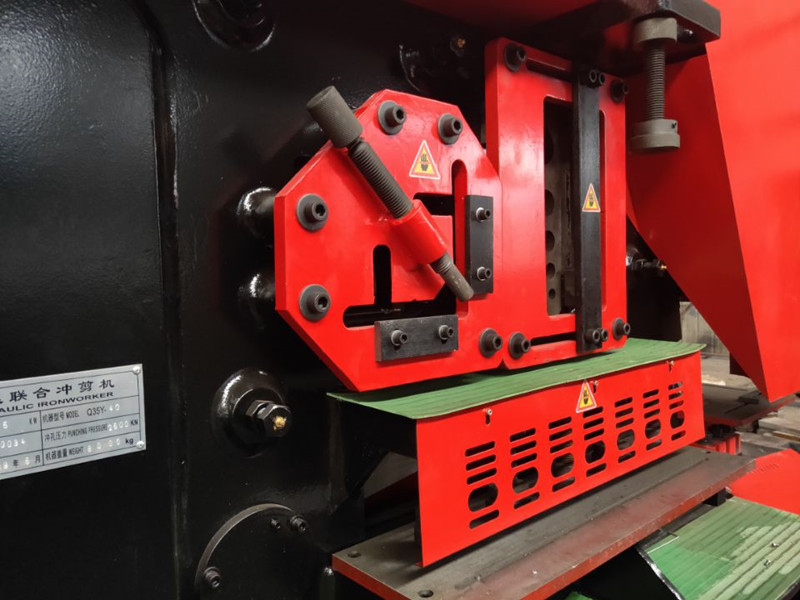

The hydraulic combined punching and shearing machine adopts the main cylinder for downward shearing movement. The upper tool post of the hydraulic

combined punching and shearing machine will swing in an arc around a fixed axis during the cutting process, and the force is applied through the fulcrum of the lever.

If it becomes smaller, the life of the shear can be increased, and the stroke of the upper tool post can be adjusted steplessly, which greatly improves the work efficiency.

He hydraulic combined punching and shearing machine is widely used in steel structure processing, storage racks, telecommunication towers, street lamps and

advertising signs and other civil facilities production enterprises.

Our hydraulic combined punching and shearing machine adopts European top processing technology. The whole frame is welded and made after high temperature

quenching treatment, so that the frame has high rigidity and high strength; the cutting tools are subjected to special vacuum high temperature treatment to extend Its service life.

The machine is equipped with punching station, channel steel and angle steel shearing station, thick plate shearing station, round steel and square steel shearing station,

and angle cutting station as standard. Accessories such as punching large holes, sheet bending, channel steel punching, blinds and pipe cutting corners can be purchased.

Standard equipped with five stations and dual hydraulic workstations. Can work independently at the same time. The machine does not need any horizontal adjustment,

and can be used after it is placed in place. Using hydraulic transmission, the whole machine is light in weight, low in noise, light and reliable, and has overload performance.

Equipped with a pipe cutting die, the pipe can be cut and beveled. The open tilting press has high efficiency, cost saving and beautiful cutting surface.

The mechanical combined hydraulic combined punching and shearing machine adopts mechanical transmission, the frame is cast steel, and the steel plate welded structure.

It has sufficient strength and rigidity to cut, punch, punch, and punch square steel, round steel, channel steel, I-beam, and angle steel. Die cut.

The hydraulic combined punching and shearing machine adopts hydraulic transmission. It is a new product of the domestic combined hydraulic combined

punching and shearing machine. It can cut plates, square steel and I-beam and is equipped with a shear stop device. The hydraulic combined punching and

shearing machine is a sheet metal and profile processing equipment integrating multiple functions. Before using any machine, we must pay attention

to some matters. For details, please see: Precautions for using hydraulic combined punching and shearing machine

What is the specific daily maintenance method of the hydraulic combined punching and shearing machine?

1. Operation method

1. Check the specific conditions of the power supply, observe whether the voltage is stable, and check whether the leakage protector and air switch are intact.

2. Open the wiring cabinet of the hydraulic combined punching and shearing machine, connect it to the line, and then close the cabinet door.

3. Power on and test the machine, if there is no problem. Observe whether the emergency stop switch is turned on.

4. Connect the foot pedal switch

5. Turn off the power every time the mold is changed

6. After the work is over, the power supply should be turned off, the power supply should be removed, and the site should be cleaned up.

2. Maintenance method

1. Before starting the machine, it is necessary to observe whether the leveling of each part of the machine is intact and whether the electrical contact is intact.

2. Before working, observe whether the hydraulic combined punching and shearing machine is lubricated, and start the machine and run it empty.

If there is no bad phenomenon, the work can be carried out.

3. Do not overload, and it is strictly forbidden to rebuild the quenched steel.

4. The staff should wear protective gear and gloves, and it is strictly forbidden to pass sandals and slippers.

5. The hydraulic combined punching and shearing machine needs to be filled with oil regularly, and the punching tool is strictly prohibited from skewing.

6. At work, you should pay attention to the protection of your fingers. When the sheet material cannot be pressed to the end, punching is prohibited.

7. During the disassembly of the machine, it is forbidden to strike a part with force.

8. It is strictly forbidden to pile a large amount of other objects in the work area, and you must stop when cleaning.

9. After the work is over, the machine should be shut down, cut off the power supply, and the site should be cleaned up.

10. Strictly control the specifications of punching and shearing sheets, and punching and shearing are prohibited when the range is exceeded.