Application of 3D metal fiber laser cutting machine equipment in automobile doors and windows

The application of 3D metal fiber laser cutting machine equipment in automobile doors and windows, along with the improvement of people’s living standards, we have more and more consumer demand relative to cars, and the automobile industry has become one of the rapidly developing industries. Technological development trends, consumption tendencies, etc., have also led to the ever-increasing efficiency of car updates, adding new technical specifications and requirements to corresponding equipment manufacturers.

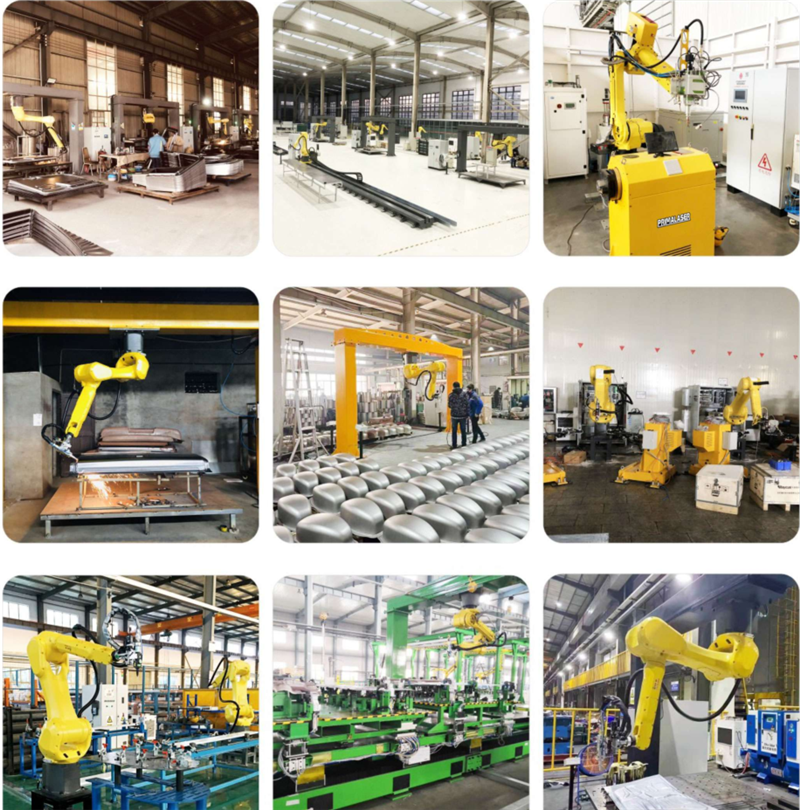

The following is the 3D metal fiber laser cutting machine equipment:

In the past, the door and window sheet metal of the car basically used the full-sequence die stamping technology. This processing method: the initial investment is large, the preparation time for operation is long, the enterprise product adjustment is laborious, the demand for talents is large, and the stamping technology is relatively complex. Especially nowadays, the speed of continuous updating of enterprise products is fast, and the varieties are gradually increasing. The production methods such as full-sequence die stamping processing are no longer suitable for the current economic environment.

Now the development and growth of the automobile door and window manufacturing industry is gradually lightweight and refined. The processing of precision parts of the car door and window sheet metal, high-quality and high-quality production and processing are the technical requirements of all industries. It is metal fiber laser cutting technology. In foreign countries, metal fiber laser cutting technology is mainly used for manipulator 3D metal fiber laser cutting machines and laser welding of special materials such as high-end car door and window shells and bottom brackets, aircraft wings and aircraft shells.

The three-dimensional metal fiber laser cutting machine equipment is composed of a special metal fiber laser cutting head, a high-precision capacitive sensor tracking system, a laser generator and a metal sheet with different wall thicknesses of the industrial manipulator system software. Advanced 3D metal fiber laser cutting machine. It uses the sensitivity and rapid operation characteristics of the industrial manipulator to manufacture and process the size of the car doors and windows according to the consumer manipulator 3D metal fiber laser cutting machine. The track can be programmed offline or offline, and the irregular product workpiece can be cut by metal fiber laser cutting head to achieve three-dimensional metal fiber laser cutting; use laser transmission to transmit the laser data to the cutting head of the manipulator three-dimensional metal fiber laser cutting machine (the cutting head of the metal fiber laser cutting machine is equipped with a special laser transmission speed Assembly and optical transmission data assembly), and then use the focusing system software to achieve focusing, and achieve multi-angle three-dimensional metal fiber laser cutting for various three-dimensional metal sheets.

metal fiber laser cutting requires the use of lasers to process various materials, such as drilling, 3D metal fiber laser cutting, scribing, laser welding, heat treatment, etc. It also does not require auxiliary tools, has a fast processing speed, and has small surface deformation. class material. Because the metal fiber laser cutting process should be a non-contact manufacturing process, and the kinetic energy and moving speed of the high-efficiency energy laser can be adjusted, it can achieve various manufacturing and processing effects, especially the high toughness, high ductility and high melting point material.

Prima Laser 3D metal fiber laser cutting machine equipment can arbitrarily adjust the relative path of the 3D metal fiber laser cutting machine according to the mathematical modeling of the customer’s product, and there is no need to open the full sequence mode. Sexual costs and expenses play a prominent role. Three-dimensional metal fiber laser cutting machine equipment is a technological change in sheet metal laser processing. The characteristics of three-dimensional metal fiber laser cutting machine equipment such as high speed, high precision, and flexible production and processing make the manufacturing industry more and more automated. It has a major role, greatly improving work efficiency and reducing costs. The relatively high sensitivity of the cutting efficiency and cutting precision of the 3D metal fiber laser cutting machine enhances the working ability of the metal fiber laser cutting head close to the production and processing range. Because of its low cost and high flexibility, the manipulator can be laser-cut by laser transmission, and its application value is favored by everyone.