Application and advantages of laser sheet metal cleaning machine technology in six major industries

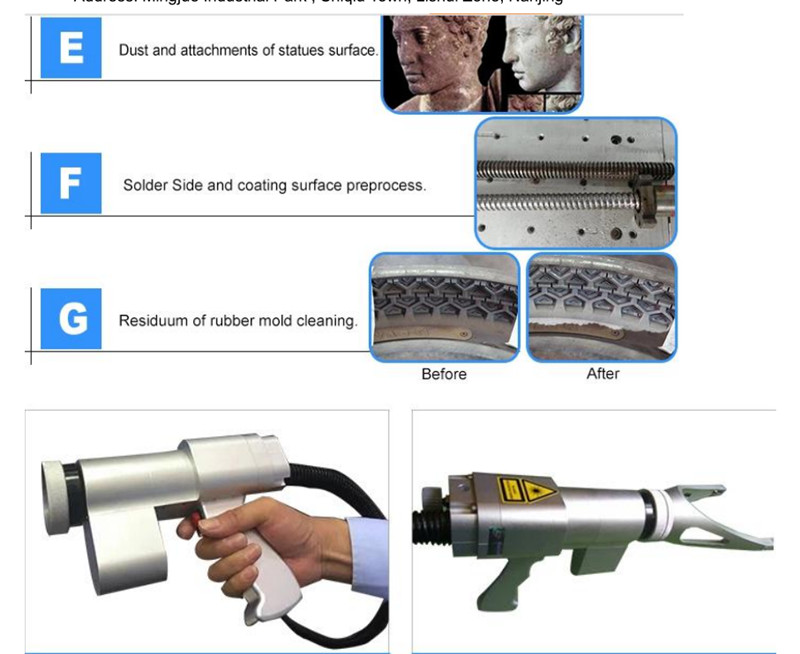

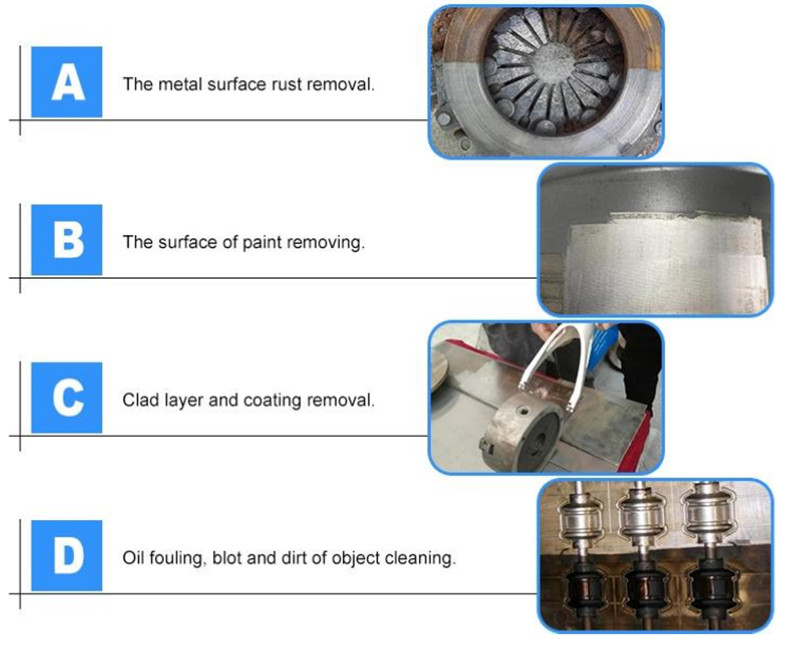

The laser sheet metal cleaning machine technology uses nanosecond or picosecond pulsed lasers to irradiate the surface of the workpiece to be cleaned by the sheet metal, so that the surface of the workpiece absorbs the focused laser energy in an instant to form a rapidly expanding plasma (a highly ionized unstable gas). ), so that the oil stains, rust spots, dust residues, coatings, oxide layers or films on the surface are vaporized or peeled off, so as to efficiently remove the surface attachments.

At present, the metal sheet cleaning methods widely used in the sheet metal cleaning industry include mechanical sheet metal cleaning, chemical sheet metal cleaning and ultrasonic metal sheet cleaning. However, under the constraints of environmental protection and the requirements of the high-precision market, their applications are subject to Great restrictions. The laser sheet metal cleaning machine has obvious advantages in various industries. The main application industries are as follows:

01

Mold industry

The laser can realize the non-contact metal sheet cleaning of the mold, which is very safe to the mold surface, can ensure its accuracy, and can clean the sub-micron dirt particles that cannot be removed by the traditional metal sheet cleaning method, and achieve true pollution-free, high efficiency and high Quality metal sheet cleaning.

02

Precision Instrument Industry

The precision machinery industry often needs to remove the esters and mineral oils used for lubrication and corrosion resistance on the parts, usually by chemical methods, and the chemical metal sheet cleaning often still has residues. Laser deesterification can completely remove esters and mineral oil without damaging the surface of the part. The laser causes the explosive vaporization of the thin oxide layer on the surface of the part to form a shock wave, which leads to the removal of dirt instead of mechanical interaction.

03

Rail industry

At present, all metal plate cleaning before rail welding uses grinding wheel and belt grinding metal plate cleaning. The base material is seriously damaged, the residual stress is serious, and a large amount of grinding wheel consumables are consumed every year, the cost is high, and serious dust pollution is caused to the environment. Laser sheet metal cleaning can provide high-quality and efficient green sheet metal cleaning technology for my country’s high-speed railway track laying production, solve the above problems, eliminate welding defects such as seamless rail holes and gray spots, and improve the stability and safety of my country’s high-speed railway operation .

04

Aviation industry

The surface of the aircraft must be repainted after a certain period of time, but the original old paint needs to be completely removed before painting. Chemical soaking/wiping is the main paint removal method in the aviation field. This method causes a large amount of chemical ancillary waste and cannot achieve partial maintenance and paint removal. This process is heavy and harmful to health. Laser metal sheet cleaning can achieve high-quality removal of surface paint on aircraft skins, and is easy to realize automated production. At present, this technology has begun to be applied to the maintenance of some high-end models abroad.

05

Shipbuilding industry

At present, the pre-production metal plate cleaning of ships mainly adopts the sandblasting method. The sandblasting method has caused serious dust pollution to the surrounding environment and has been gradually banned, which has caused the production of ship manufacturers to reduce or even stop production. The laser metal sheet cleaning technology will provide a green and pollution-free metal sheet cleaning solution for the anti-corrosion spraying of the ship’s surface.

06

Military industry

Laser metal sheet cleaning technology is widely used in weapon maintenance. The laser metal sheet cleaning system can remove rust and pollutants efficiently and quickly, and can select the removal part to realize the automation of metal sheet cleaning. Using laser metal sheet cleaning, not only the cleanliness is higher than the chemical metal sheet cleaning process, but also almost no damage to the surface of the object