Analyze the function and characteristics of Metal Sheet Two-roller Rolling Machine

The main machine is the main structure of the sheet metal two-roller rolling machine

The structure of the sheet metal two-roller rolling machine equipment is mainly the main machine, the hydraulic station, and the three most electrical control cabinets. When working,

the first one will output the high-pressure electric oil pump and the high-pressure oil pipe and then enter the in-cylinder folding machine to work. The electric motor folding machine,

high-voltage plunger oil power generation will drive the motor, and then can achieve the purpose of processing.

When operating the metal sheet two-roller rolling machine, the forming effect is very good, the efficiency is high, and the working speed is fast. After installation, it should be installed

on a hard surface. This equipment can maintain a stable job during our working time. , Should also strictly abide by the rules and regulations and related operation process, the operator

should be familiar with the working principle and maintenance of the crimping machine.

There is a very important relationship between the maintenance and service life of the sheet metal two-roller rolling machine. In the process of use, as long as the continuous maintenance is performed, the relevant work is done to ensure that the use becomes smoother. The order of operation, work according to the order.

- The transmission of the lower roller of the sheet metal two-roller bending machine is realized by the main motor through the main reducer. The output shaft of the main reducer is transmitted to the two lower rollers through a set of gears. The change of the roller transmission direction is changed by the main motor. get.

- The realization of the lifting movement of the upper roller of the sheet metal two-roller bending machine is that the auxiliary motor drives the worm and worm gear mechanism under the bearing housing of the left and right rollers through the auxiliary reducer to move the nut fixed on the worm wheel to rotate, thereby making The lifting screw rod moves up and down to complete.

- The unloading device is used to lift the upper roller into position when the cylindrical part is rolled, before the left bearing is removed to tilt the bearing seat, and the upper roller is pulled

- by the balance rod at the end of the upper roller, and then the The upper pin of the tilting bearing seat is pulled out, and the tilting bearing seat is turned over, and the rolled workpiece can be released from one end of the upper roller.

- The electrical part adopts brand-name high-quality products, stable action, long life, safe and reliable, and easy to operate.

The two-roller bending machine is a high-quality product developed and developed by our company with the introduction of foreign advanced technology. The main features are as follows:

- Mainly used for rolling of thin plates (1~3mm), suitable for industries such as water heaters and fire-fighting equipment.

- It can be used as a stand-alone machine or with a production line.

- The production efficiency is extremely high, and a working beat is completed every 30 seconds. (Complete the production of a finished product)

- The entire process of feeding, centering, feeding, rolling, and discharging is automatically controlled by the computer.

- The reel can be completed at one time, which can completely eliminate the remaining straight edges.

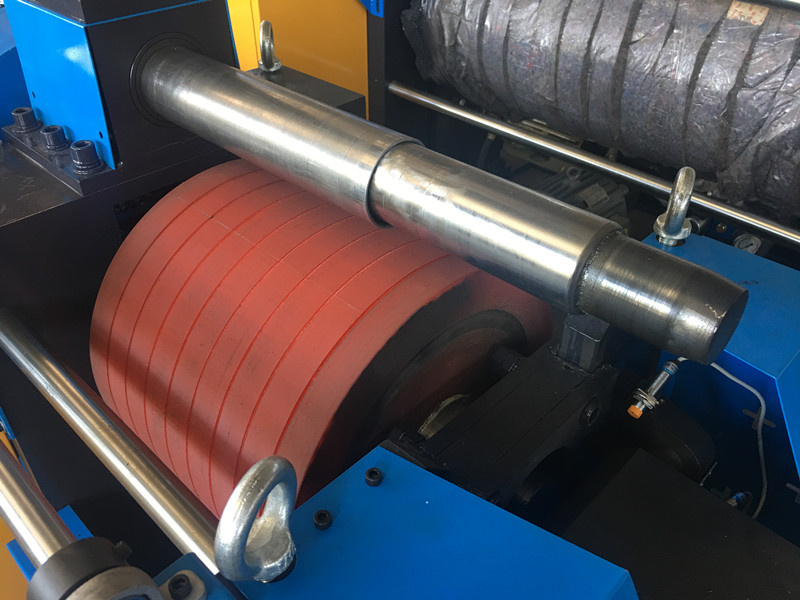

How does it work? One of the rolls is made of a highly elastic composite material, so that the two rolls are in a superimposed position, so that the elastic roll is recessed. When the roll rotates,

the plate is rolled in, and the material is rolled up by its bonding surface. .

How does the two-roll machine work? The two-roller machine is composed of two rollers, which is different from the three-roller machine: the three rollers of the three-roller machine are

all rigid rollers and are made of metal. The two-roller machine has only one rigid roller, and the other is a flexible roller, made of rubber. When working, the servo motor drives the flexible

roller to press against the rigid roller, and the deformation of the flexible roller causes the material to be deformed into a qualified shape. Due to the use of flexible rollers, the two-roller machine does not have any abrasion on the surface of the plate, which is very suitable for stainless steel materials.