Several issues affecting metal plate cnc press brake bending accuracy

metal plate cnc press brake bending is a very important process in sheet metal processing, but sometimes inaccurate metal plate cnc press brake bending may occur, which greatly affects production efficiency and product quality. This article will explore the reasons for inaccurate sheet metal metal plate cnc press brake bending, helping you better understand and solve this problem.

1、Material issues

- Material deformation

During the sheet metal metal plate cnc press brake bending process, if there are deformation issues with the material itself, it will affect the accuracy of the metal plate cnc press brake bending process, such as., Steel may experience local deformation or distortion during rolling, cooling, and other processes, leading to errors during metal plate cnc press brake bending.

- Uneven material hardness

The hardness of sheet metal materials is one of the important factors affecting metal plate cnc press brake bending accuracy. If the material hardness is uneven, it will lead to uneven stress during the metal plate cnc press brake bending process, resulting in metal plate cnc press brake bending angle deviation.

- Uneven thickness difference of sheet metal

The thickness of sheet metal materials is also one of the important factors affecting metal plate cnc press brake bending accuracy. If the material thickness is uneven, it will lead to uneven stress during the metal plate cnc press brake bending process, resulting in deviation in the metal plate cnc press brake bending angle.

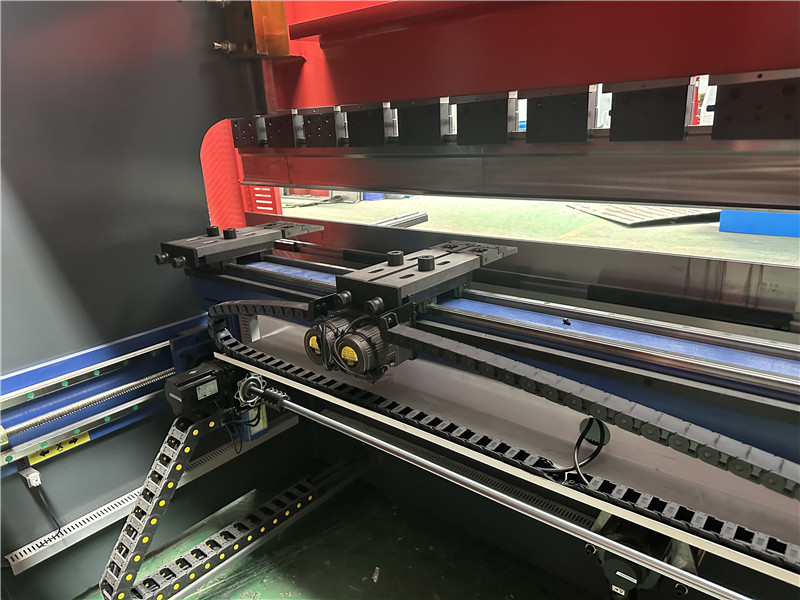

2、 Mold problems

- The mold accuracy is not high

Mold is one of the core equipment for sheet metal metal plate cnc press brake bending. If the accuracy of the mold is not high, it will lead to errors during the metal plate cnc press brake bending process. For example, rough surface of the mold, dimensional deviation, etc.

- Mold wear affects metal plate cnc press brake bending

During the metal plate cnc press brake bending process of sheet metal, the mold may wear out due to prolonged use, resulting in errors during the metal plate cnc press brake bending process. For example, the wear of the mold blade can lead to deviation in the metal plate cnc press brake bending angle.

3、 Operational issues

- Improper operation

Improper operation can also lead to inaccurate sheet metal metal plate cnc press brake bending, inexperienced operator skills, and improper operation sequence.

- Insufficient metal plate cnc press brake bendingpressure.

During sheet metal metal plate cnc press brake bending, pressure is very important. If the pressure is insufficient or excessive, it can lead to insufficient pressure during the metal plate cnc press brake bending process, resulting in deviation of the metal plate cnc press brake bending angle, while excessive pressure can cause damage to the sheet metal material.