Description

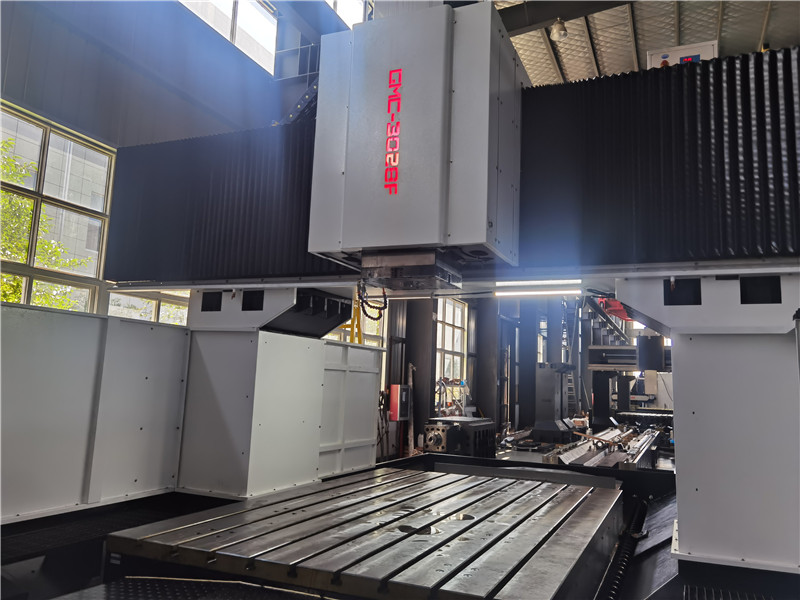

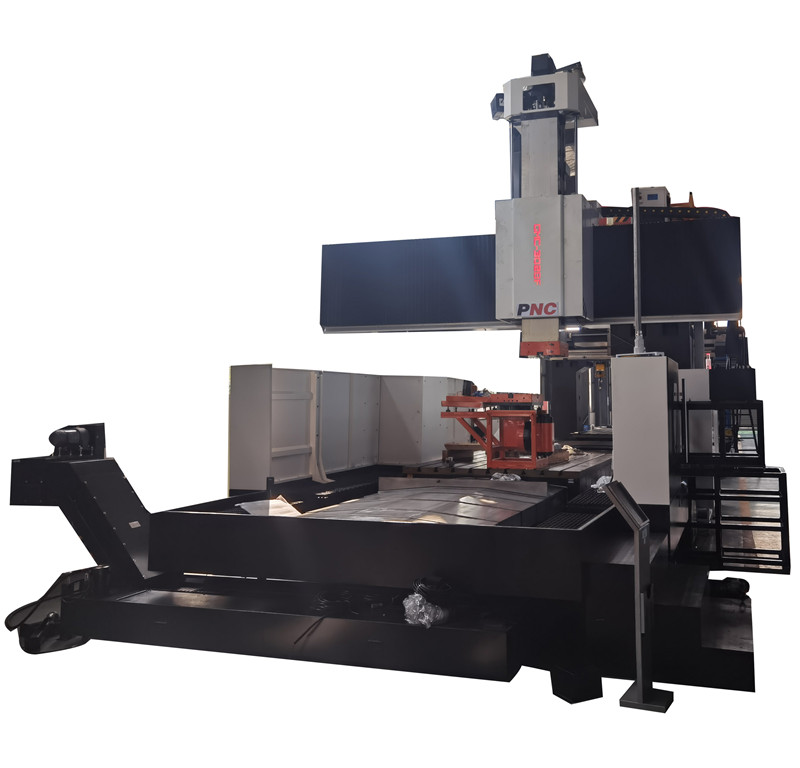

Double Column Machining Center /4 Axis 5 Axis CNC Machining Center/Heavy Duty Gantry Milling Machine

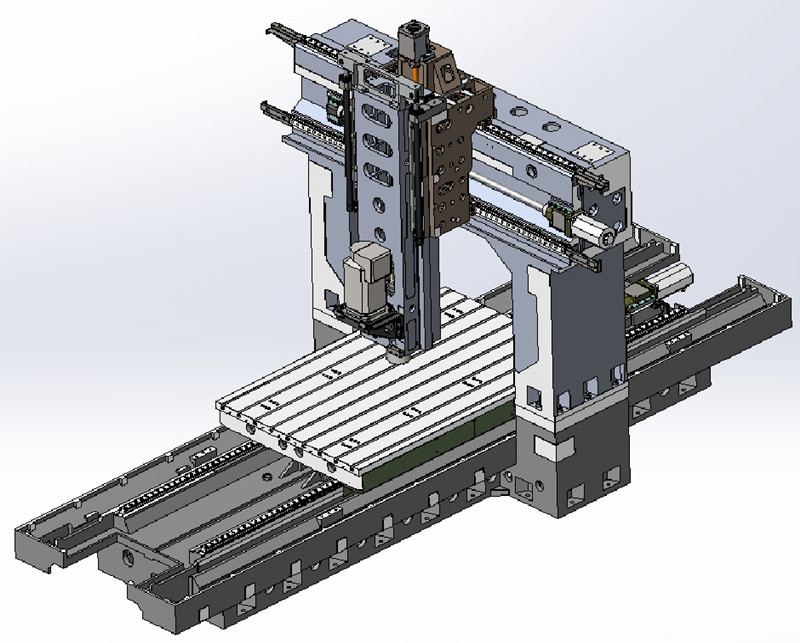

The overall layout of the CNC gantry milling machine is a fixed beam and fixed column gantry frame structure, the base is fixed, and the worktable moves in the X direction on the base; the column is fixed on the base, the beam is fixed on the column, and the slide moves in the Y direction on the beam; the ram moves on the slide Move up in Z direction

|

Performance

|

GMC-2217

|

GMC-3018

|

GMC-4032

|

GMC-6035

|

|

|

Travel

|

|||||

|

Work table travel(X/Y/Z)

|

mm

|

2200/1700/1000

|

3000/1800/1000

|

4000/3200/100

|

6000/3500/1200

|

|

Distance from spindle surface to worktable

|

mm

|

0-1200

|

0-1200

|

0-1400

|

0-1600

|

|

Rail way

|

Two linear guide rail, one hardened rail

|

||||

|

Work table

|

|||||

|

Table size

|

mm

|

2200×1300

|

3000×1500

|

4000×1800

|

6000×2500

|

|

The maximum load capacity of the workbench

|

T

|

5

|

7

|

12

|

20

|

|

Splindle

|

|||||

|

The spindle taper(model sleeve diameter)

|

mm

|

BT50/155

|

BT50/155

|

BT50/190

|

BT50/190

|

|

The spindle motor power

|

kw

|

18

|

22

|

26

|

30

|

|

Splindle speed

|

rpm

|

6000

|

6000

|

6000

|

6000

|

|

Accuracy

|

|||||

|

Position Precision

|

mm

|

0.01/1000

|

0.01/1000

|

0.01/1000

|

0.01/1000

|

|

Repeated position precision

|

mm

|

±0.01

|

±0.01

|

±0.01

|

±0.01

|

|

Size

|

|||||

|

Net weight

|

T

|

23

|

30

|

40

|

75

|

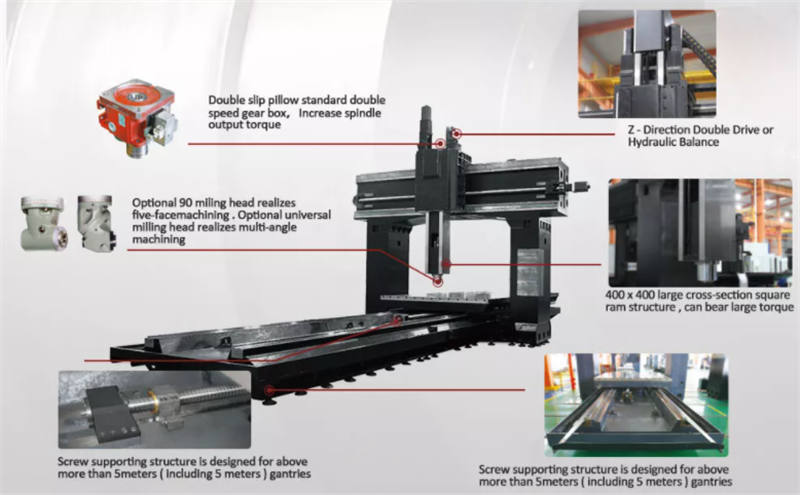

The main large parts of the machine tool: the base, worktable, column, beam, sliding seat and ram are all made of high-quality resin sand, high-strength and high-quality cast iron, and have a perfect heat treatment process to eliminate residual stress, and arrange enough reinforcing rib plates. Ensure that the whole machine has sufficient strength, rigidity and high stability

High rigidity, long-term accuracy retention

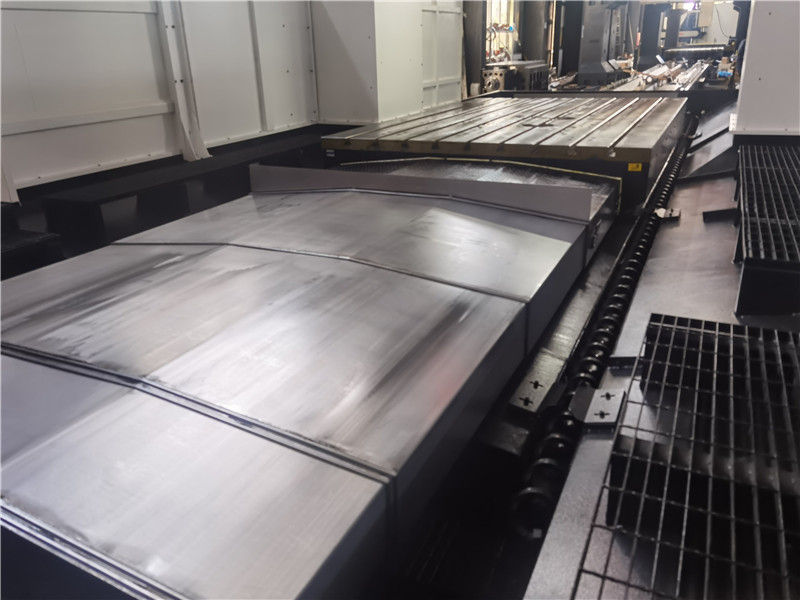

X-axis can adopt 2/3/4 heavy-duty roller guide rails, with heavy load capacity, strong rigidity and good dynamic accuracY.

High rigidity, long-term accuracy retention

The three-axis transmission adopts Taiwan brand large-diameter ground double-nut ball screw, which is compact in

structure, stable in motion and high in precision. The screw support adopts precision screw support bearings, and

both ends are pre-stretched to eliminate precision loss caused by thermal elongation.

High rigidity, long-term accuracy retention

The beam adopts a stepped structure, the cross-section of the beam is large, the span of the guide rail is large, the distance from the center of the spindle to the guide rail surface is short, the turning moment is small, and the structural rigidity is good. The Y-axis adopts the two upper and one lower, three guide rails to hang the sliding seat, which reduces the influence of the gravity of the sliding seat on the Z-axis.

High efficiency

The spindle speed can reach 8000rpm, and the three-axis rapid movement can reach 8/12/10m/min.

Large processing range

Compared with machine tools of the same specification, the ultra-wide door width of the machine tool ensures a wider

processing range, and the X-axis adopts two heavy-duty guide rails. The bearing is heavy, and the Y-axis adopts three heavy-duty guide rails to ensure the shock resistance of the machine head. The super height of the Z axis ensures the

passage of the gantry.

Q1: Are you factory or Trade company? A1: We are factory. Our factory have more than 20 years experience in production various CNC machine.We provide final solution for machining manufacturing industry. Q2: How to choose the suitable machine? A2: Tell us your max workpiece size(such as max length,max width, max height and weight) and photo. We can recommend the suitable machine for you. Q3: Can you supply customized service? A3: We can customized according to customer’s special requirements. Q4: How to intall and operate of the machine? A4: Enough photoes, video and operation manual will be supplied.It will show how to operate the machine. Our engineers also provide online technical support Q5: What is the payment item? A5: 50% T/T in advance , 50% balance will be paid before machine leave the seller’s factory.