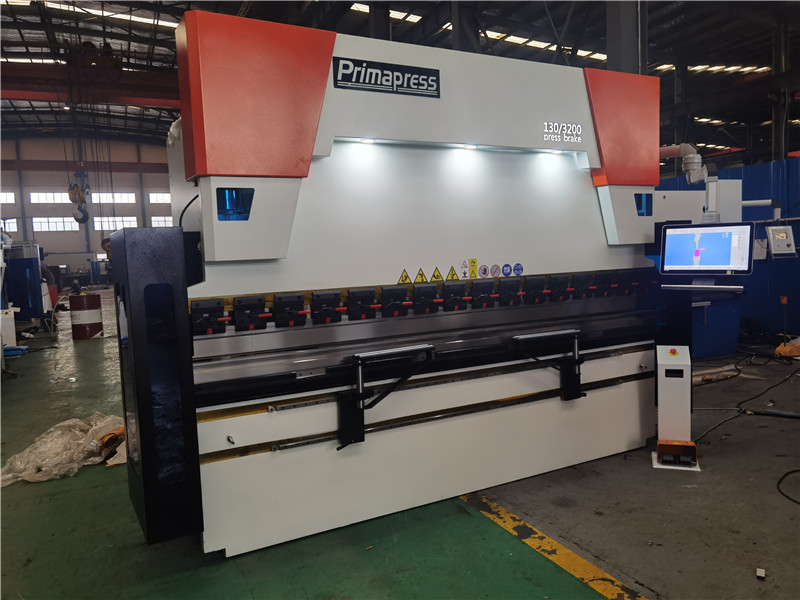

Composition and Introduction of Electro hydraulic Servo Synchronous NC press brake Bending Machine

Brief Introduction of Electro hydraulic Servo Synchronous CNC press brake Bending Machine

The main cylinders on both sides are synchronously controlled by a closed loop composed of an electrohydraulic servo valve imported from Germany and a grating ruler from HEIDENHAIN, Germany. The feedback is accurate and the slider runs accurately, so that the bending accuracy and the slider’s repeated positioning accuracy are high. ● The hydraulic bulge automatic compensation system is adopted to solve the influence of the deformation of the slider during bending on the workpiece quality. The compensation quantity is automatically adjusted by the numerical control system, which is convenient and accurate. ● The rear stopper mechanism with complete functions is adopted, and multiple rear stopper shafts can be selected for control. Functional parts in the rear stopper. For example, the guide rail, lead screw, bearing, etc. are all imported components to ensure the accuracy of the rear stopper. ● The machine body adopts an integral welded structure, which is convenient for transportation and processing, and can ensure the overall accuracy of the machine tool. ● The machine body, sliding block and other important parts are analyzed with ANSYS finite element analysis software to ensure the reliability of the machine tool. ● The hydraulic system adopts the integrated control system imported from Germany, which reduces the pipeline installation, improves the working stability of the machine tool, and has a beautiful and simple appearance.

system

The press brake Bending Machine is to use the equipped mold (general or special mold) to bend the metal plate in the cold state into workpieces of various geometric cross-section shapes. The press brake Bending Machine generally uses the special CNC system for the press brake Bending Machine. The coordinate axis of the press brake Bending Machine has developed from a single axis to 12 axes. The CNC system can automatically realize the control of the sliding block’s running depth, the adjustment of the sliding block’s left and right tilt, the front and back adjustment of the rear stopper, the left and right adjustment Pressure tonnage adjustment and slider approaching working speed adjustment, etc. The press brake Bending Machine can conveniently realize the sliding block downward, inching, continuous, pressure maintaining, return, midway stop and other actions, and complete the multi elbow bending at the same angle or different angles at one time [1].

Composition of Electro hydraulic Servo Synchronous NC press brake Bending Machine

slider

Sliding block part: hydraulic transmission is adopted, and the sliding block part is composed of sliding block, oil cylinder and mechanical stop micro adjustment structure. The left and right cylinders are fixed on the frame, and the piston (rod) drives the slider up and down through hydraulic pressure. The mechanical stop is controlled by the numerical control system to adjust the value.

workbench

Workbench part: it is operated by the button box to make the motor drive the stopper to move forward and backward, and the moving distance is controlled by the numerical control system. The minimum reading is 0.01 mm (there are travel switch limits in the front and back positions).

synchronous system

Synchronous system: different from ordinary press brake Bending Machine, this machine uses servo valve, grating ruler and other hydraulic devices to form a closed loop, so as to accurately control various actions of the press brake Bending Machine.

Material retaining mechanism

Material retaining mechanism: the material retaining mechanism is driven by a motor, which drives two screw rods to move synchronously through chain operation, and the numerical control system controls the material retaining size.

Accuracy of Electro hydraulic Servo Synchronous NC press brake Bending Machine

The repeated accuracy of the slider of CNC press brake Bending Machine is ± 0.0004 inch, and the accurate angle of forming must adopt such accuracy and good mold. The repeat accuracy of the slider of the manual press brake Bending Machine is ± 0.002 inch, and the deviation of ± 2~3 ° will generally occur under the condition of using the appropriate mold. In addition, CNC press brake Bending Machine is ready for rapid mold installation. When you need to bend many small batches of parts, this is an unquestionable reason to consider.