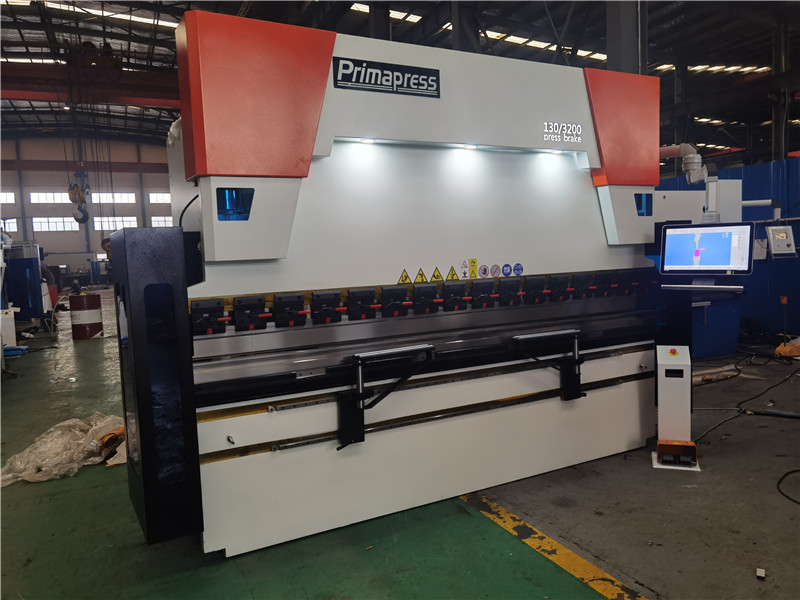

Application of the cnc press brake bending machine for sheet metal bending and material

The common technology operation is now used in the sheet metal bending process of the cnc press brake bending machine. The reason why the sheet metal bending process of the cnc press brake bending machine becomes so common is that it is simple and convenient compared with other processing technologies, and can help enterprises improve economic benefits. The production process will directly affect the cost of production parts, and the parts to be sampled are usually small batches. If there is no indication of specific subsequent processing amount, the cnc press brake bending machine is usually used for sheet metal bending. If there is a batch of sheet metal parts, the bending process of the cnc press brake bending machine is not as good as the stamping process. Why is the sheet metal bending process of the cnc press brake bending machine widely used? What are its advantages?

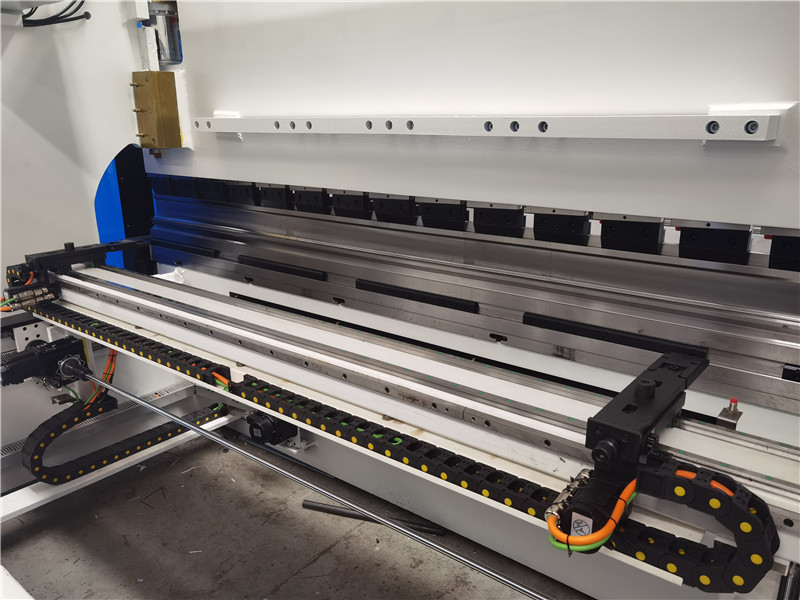

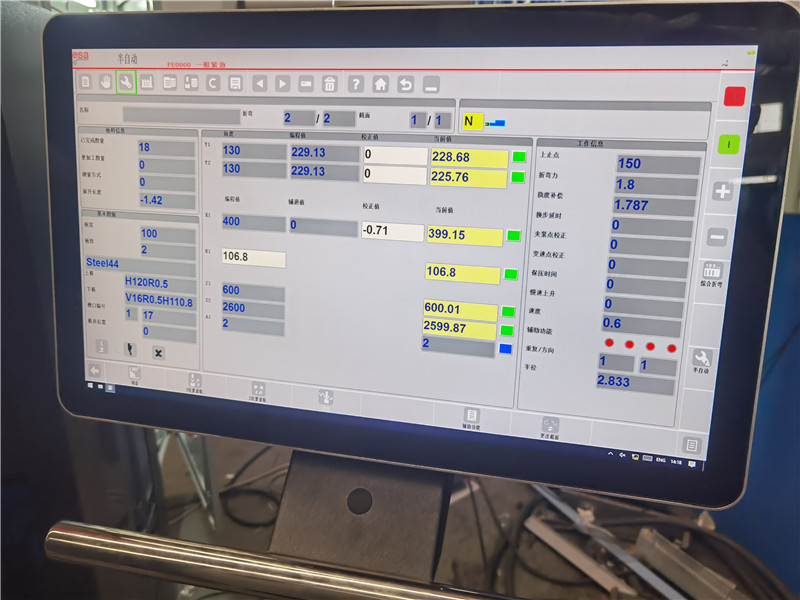

We should first understand the content of the bending process of the cnc press brake bending machine sheet metal. There are cutting, deburring, bending, secondary processing, spraying and other processing technologies. These processes are done manually by deburring, and the rest is done by machine. The manufacturers of precision cnc press brake bending machine sheet metal bending process believe that these processes can be mechanized and automated through positioning fixture, thus greatly improving the processing efficiency and production quality of parts. Cutting equipment is an obvious example. CNC punches, laser machines, shears, etc. of cutting equipment are all automated with positioning fixtures. The original point and X and Y coordinates of these equipment are set before leaving the factory, and the advantages of using CNC punch to solve the bending process of sheet metal of the cnc press brake bending machine are solved.

Introduction to Common Materials for Sheet Metal Bending Process of cnc press brake bending machine

- Galvanized steel plate SECC

The base material of SECC is ordinary cold-rolled steel coil. After degreasing, pickling, electroplating and various post-treatment processes in the continuous electrogalvanizing production line, it becomes an electrogalvanizing product. SECC not only has the mechanical properties and similar processability of ordinary cold-rolled steel sheets, but also has superior corrosion resistance and decorative appearance. In the market of electronic products, home appliances and furniture, it has great competitiveness and substitutability. For example, SECC is widely used in computer cases.

- Ordinary cold-rolled sheet SPCC

SPCC refers to the continuous rolling of steel ingots into steel coils or sheets of required thickness by cold rolling mill. The SPCC surface has no protection, and is easily oxidized when exposed to the air, especially in the humid environment where the oxidation speed is accelerated and dark red rust appears, so the surface shall be painted, plated or otherwise protected during use.

- Hot dip galvanized steel sheet SGCC

Hot dip galvanized steel coil refers to the semi-finished product after hot rolling pickling or cold rolling, which is cleaned and annealed, immersed in a solution zinc bath with a temperature of about 460 ° C, coated with zinc, and then quenched, tempered, leveled and chemically treated. SGCC material is harder than SECC material, with poor ductility (avoid deep drawing design), thicker zinc layer and poor electric weldability.

- Stainless steel SUS304

As one of the most widely used stainless steels, it has better corrosion resistance and heat resistance than the steel containing Cr (chromium) due to its Ni (nickel) content. It has very good mechanical properties, no heat treatment hardening and no elasticity.

- Stainless steel SUS301

The content of Cr (Cr) is lower than that of SUS304, and the corrosion resistance is poor. However, after cold processing, good tension and hardness can be obtained in the stamping process, and the elasticity is good. It is mainly used for spring and EMI prevention.