Steps of the electro-hydraulic servo synchronous press brake bending machine for bending arcs and complex workpieces!

The “three good”, “four good” and “three good” of the operator of the electro-hydraulic servo synchronous press brake bending machine: manage the equipment well, use the equipment well and repair it well; Four skills of equipment: know how to use, maintain, check and troubleshoot the equipment. Before operation, it is necessary to check and remove all the sundries around the work site that hinder the work and traffic. There shall be no oil stain on the ground to avoid slipping. Workpieces shall be stacked neatly and firmly. Check whether the oil filling points of each part are lubricated, and add oil in time in case of oil shortage or insufficient oil. Check whether the protective device is in good condition, and whether the electrical circuit switch and grounding are in good condition. Check whether the machinery operates normally and whether the electrical switch is sensitive when the vehicle runs empty.

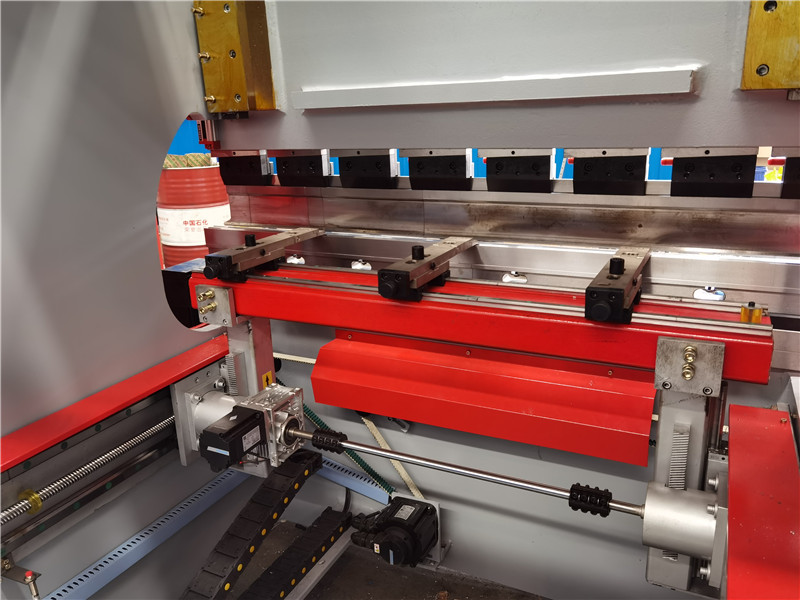

Electro hydraulic servo synchronous press brake bending machine uses ordinary knife to bend arc:

- Select 0.2R ordinary upper mold and lower mold according to the mold selection standard, calculate the arc length, calculate the number of cutters to complete the arc according to the arc length and material thickness, calculate the bending angle of each bend according to the arc angle and the number of cutters to be bent, and then bend. However, because the arc forming process is formed by bending several or even dozens of tools, the size range of the bending arc is limited by the tool.

The general processing range is: 1) forming 90 degree arc: arc forming above R12; 2) Forming circular arc above 120 degrees: it can process all R arcs larger than the tool.

- Processing precautions: the selection of tools shall be determined according to the processing method. For example, the selection of V-groove width shall be determined according to the feed amount.

Precautions for processing of electro-hydraulic servo synchronous press brake bending machine:

1) When converting the R mold into circular arc, first pay attention to selecting the mold according to the mold selection standard. However, when processing a 90 degree arc, due to the rebound of the processed sheet metal parts, when the lower die is 90 degrees, the 90 degree arc cannot meet the requirements, so it needs to be pushed manually during processing to ensure the processing angle. Therefore, under the premise of 88 degree lower die, 88 degree lower die should be selected when processing 90 degree circular arc.

2) When machining circular arcs, it is required to use a detection jig to detect, so as to ensure the processing appearance size.

3) When processing the process angle arc, it is generally processed with an easy die or manually.

4) Use R die (round bar and arc cutter)

Select the width standard of the lower die V-groove for the arc folding:

(1) The width of V groove of lower die selected for bending 90 degree arc is: V>2 (R+T);

(2) The width of V groove of lower die selected for bending 135 degree arc is: V>1.5 (R+T).